Sensitive membrane and corrosion Bragg grating-based corrosion sensor and equipment

A sensitive film and sensor technology, applied in instruments, scientific instruments, weather resistance/light resistance/corrosion resistance, etc., can solve problems such as corrosion monitoring and early warning, achieve high sensitivity and realize the effect of distributed measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific examples and drawings.

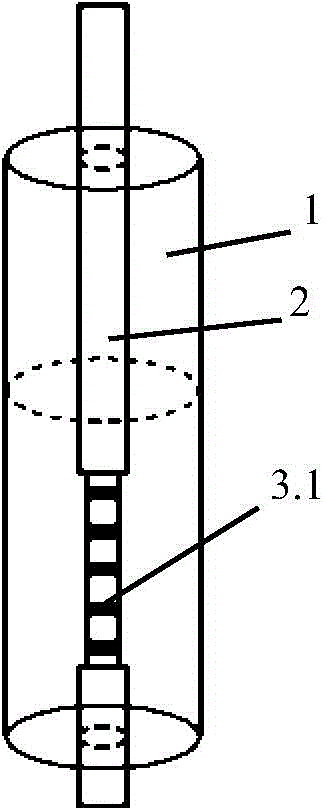

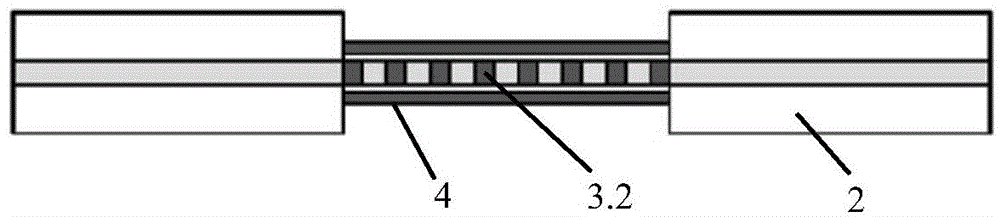

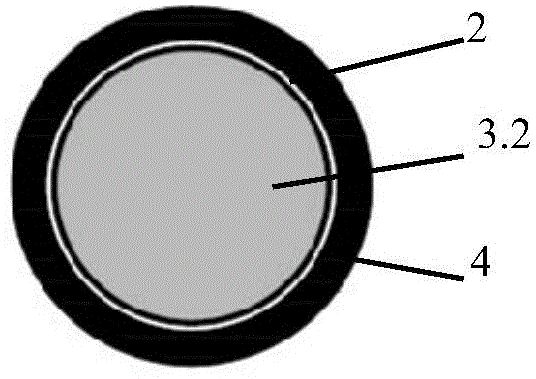

[0030] This embodiment provides a corrosion sensor based on a sensitive film and an etched Bragg grating such as figure 2 with image 3 Shown, including optical fiber, written on the optical fiber is etched Bragg grating 3.2, etched Bragg grating 3.2 is deposited with a sensitive film 4, the material of the sensitive film 4 is the same as the metal to be monitored, the thickness is 10nm-1μm; wherein the Bragg grating is etched The diameter of 3.2 is 8.6-12μm. Compared with the unetched state, the center wavelength of the grating is reduced by 2-6nm, and the center peak attenuation is 10-20dBm. The other parts of the optical fiber are covered with a protective cladding 2.

[0031] The preparation method of the rust sensor based on the sensitive film and the etched Bragg grating includes the following steps:

[0032] S1. Pretreatment of grating: take the optical fiber w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com