High-precision full-automatic FPC (Flexible Printed Circuit) defect detecting device and detecting process

A defect detection, fully automatic technology, applied in the direction of measuring devices, using optical devices, optical testing flaws/defects, etc., can solve the problems of long manual detection time, high image density, high false alarm rate, etc., to simplify FPC defect detection Technology, high-precision detection, and the effect of reducing the false alarm rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The above content has fully described the present invention. In order to have a clearer understanding of the technical characteristics, purpose and effect of the present invention, the specific implementation of the present invention will now be described in detail with reference to the accompanying drawings.

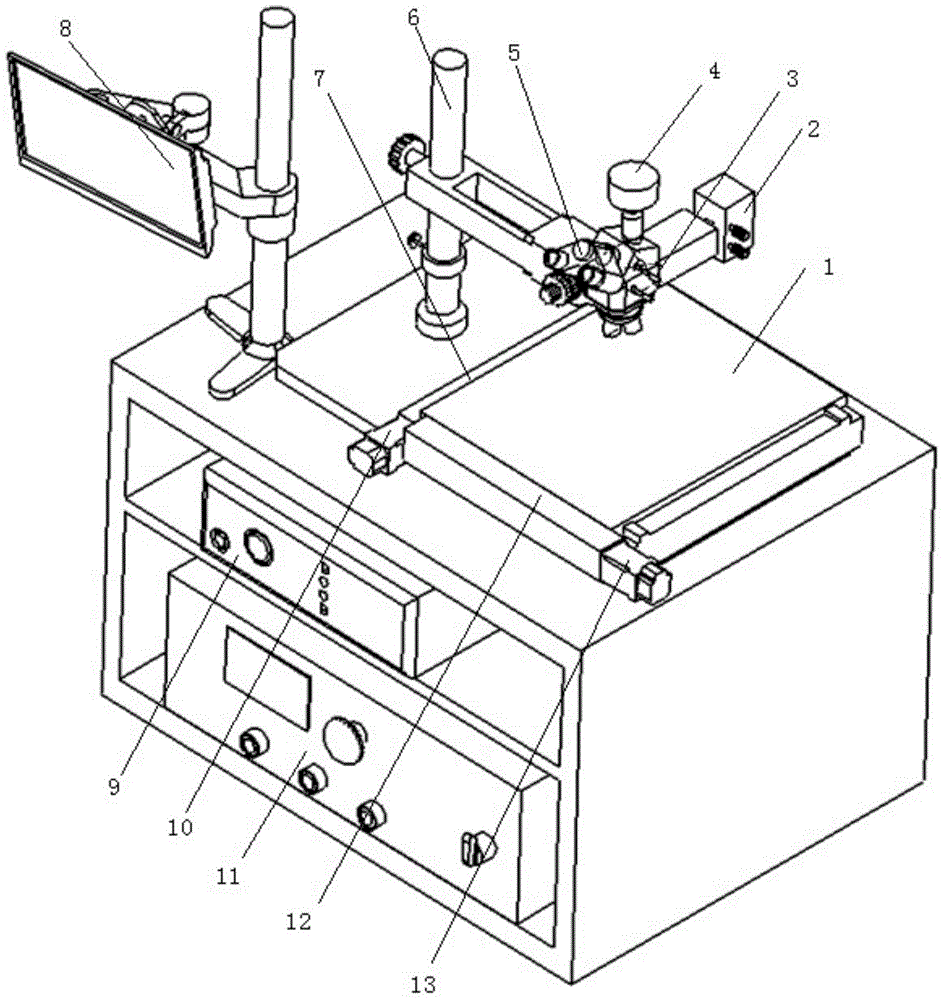

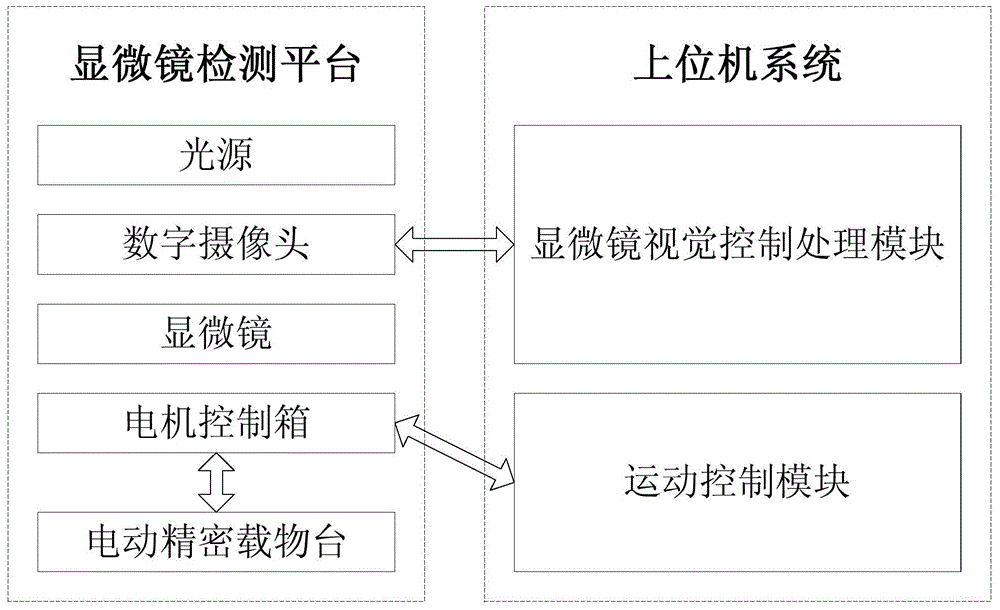

[0031] The high-precision automatic FPC defect detection device described in this example is as follows: figure 1 and 2 As shown, including the host computer system and microscope detection platform. The host computer system includes a microscope vision control processing module and a motion control module. The microscope detection platform includes an electric precision stage 1, a light source 2, a conversion rod 3, a digital camera 4, a microscope 5, a microscope fixing bracket 6 and a motor control box 11. Wherein, the electric precision stage 1 includes an X-axis servo motor 10 , a Y-axis servo motor 13 , an X-axis motion guide rail 7 , and a Y-axis motion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com