Resin lens printed with infrared up-conversion luminescent material on surface and manufacturing method of resin lens

An infrared up-conversion, resin lens technology, applied in optics, optical components, optical components, etc., to enhance the atmosphere and improve the effect of artistic rendering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0029] 1. Take 1g of the lanthanum series infrared up-conversion infrared excitation wavelength 980nm red rare earth luminescent powder material produced by Shanghai Kerun Photoelectric Materials Co., Ltd., 5-10g of solvent-based transparent screen printing ink produced by Dongguan Meiji Polymer Material Co., Ltd., Stir well and mix evenly to make luminous ink and put it into the ink box of the pad printing machine for standby.

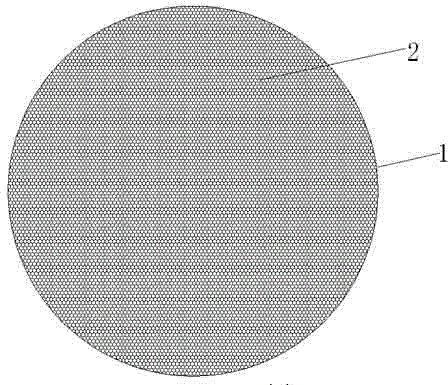

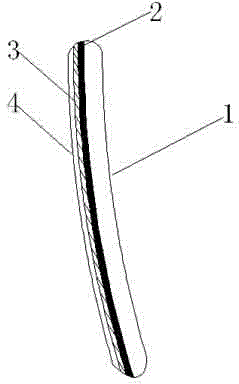

[0030] 2. The surface of the resin substrate 1 is bombarded with a plasma machine for surface activation treatment, and the surface activation treated resin substrate 1 is placed on the pad printing machine to print the ink pattern of the infrared luminescent grid layer 2 doped with rare earth elements.

[0031] 3. Put the resin substrate 1 printed with the ink pattern of the infrared luminescent grid layer 2 on the surface into a 60° C. oven and bake for 20 minutes, so that the pattern is initially cured.

[0032] 4. Move the ink-cured resin subs...

Embodiment 2

[0035] Take 1g of lanthanum series infrared up-conversion infrared excitation wavelength 980nm green rare earth luminescent powder material produced by Shanghai Kerun Photoelectric Materials Co., Ltd., 5-10g of solvent-based transparent screen printing ink produced by Dongguan Meiji Polymer Material Co., Ltd., and stir well After mixing evenly, make luminescent ink and put it into the ink box of pad printing machine for standby. Its follow-up manufacturing process method is the same as embodiment 1.

Embodiment example 3

[0037] Take 1g of lanthanum series infrared up-conversion infrared excitation wavelength 980nm blue rare earth luminescent powder material produced by Shanghai Kerun Optoelectronic Materials Co., Ltd., 5-10g of solvent-based transparent screen printing ink produced by Dongguan Meiji Polymer Material Co., Ltd., stir and mix well After uniformity, make luminous ink and put it into the ink box of pad printing machine for standby. Its follow-up manufacturing process is the same as the implementation case 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com