Disposable tea processing technology

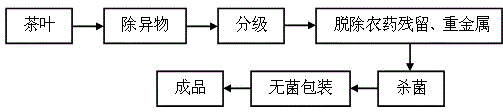

A processing technology, a technology for washing-free tea, which is applied in the direction of pre-extraction tea treatment, food preparation, food science, etc., can solve the problem of pesticide residues and heavy metals not being removed, and achieves improved quality, hygiene and safety, and tea aroma. , the effect of degrading pesticide residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Take the production of 10kg green tea disposable tea as an example to describe in detail.

[0020] Take 10kg of dry green tea and slowly add it to the inlet of the electrostatic sorting device. After being sorted, the material is placed on the conveyor belt from the outlet at a constant speed, and then enters the inlet of the color sorter through the electromagnetic cleaning device. Classification is carried out in the sorting machine. After classification, the materials flow into different conveyor belts and are transferred to the next process. After color selection, the tea leaves enter the ozone-microwave device. The ozone concentration is 5mg / L, the microwave processing power is 0.2w / g, and the microwave processing time is 5min. , and the microwave treatment is intermittent treatment, every 1min for 30s, the above ozone treatment and microwave treatment are carried out at the same time, and the degradation rate of pesticides is 95%.

[0021] After the ozone-microwav...

Embodiment 2

[0024] In Example 1, the parameters of ozone-microwave treatment are changed to: adopt ozone concentration 6mg / L, microwave treatment power 0.2w / g, microwave treatment time 5min, and microwave treatment is intermittent treatment, every 1min treatment 30s, pesticide degradation The rate reached 98%.

[0025] Using ozone-microwave to degrade pesticide residues in tea leaves will not affect the active ingredients in tea leaves. The degradation rate of pesticide residues in tea leaves can be as high as 98%, and can enhance the aroma of tea leaves; supercritical complexation extraction is used to remove residues in tea leaves The removal rate of heavy metal components reaches 90%, and the complexing agent will not remain in the tea leaves. After the removal, the residual heavy metal content in the tea leaves is lower than the national general food hygiene standards. After extraction, the tea polyphenols, theanine, etc. The effect of active ingredients is small. Before and after ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com