Medicine for treating skin diseases and preparation method of medicine

A technology for skin diseases and medicines, applied in the field of medicines for the treatment of skin diseases and their preparation, can solve the problems of treating symptoms but not the root cause, incomplete extraction of active ingredients of medicines, influence on the curative effect of medicines, etc., and achieves remarkable effects, clearing blood toxins in the body, and recovering. skin health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

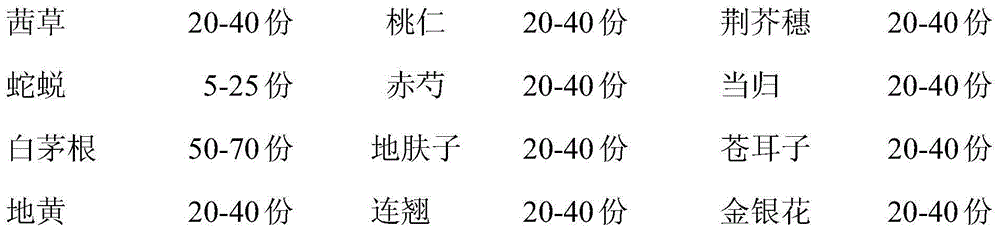

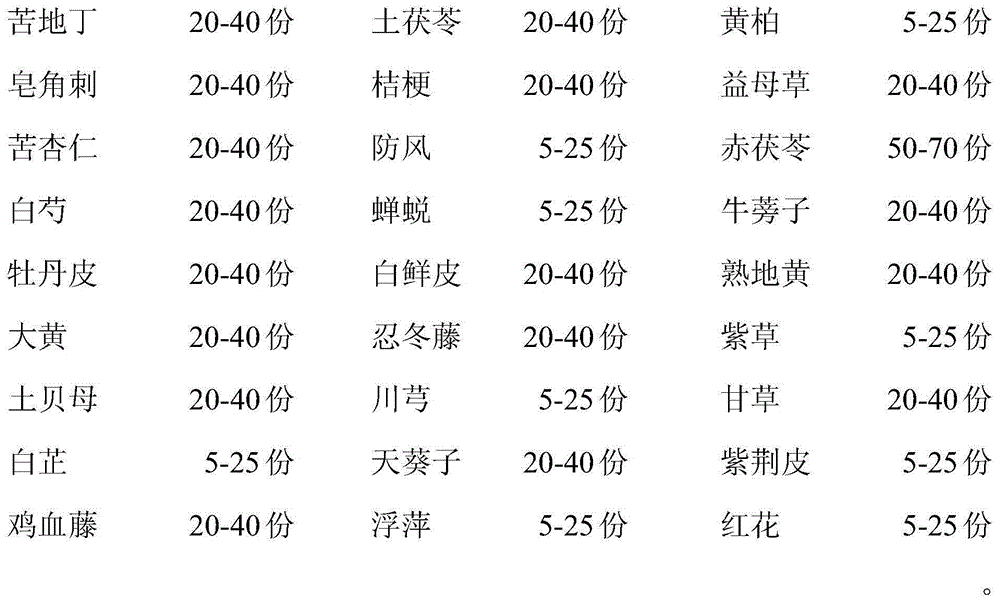

[0054] A medicine for treating skin diseases, comprising raw materials by weight of:

[0055]

[0056]

[0057]The method for preparing the above-mentioned medicine comprises the following steps: first, select 39 medicinal materials according to the above weight, and mix the 39 medicinal materials evenly; then crush the above-mentioned raw materials into coarse powder, place them in an oven, and sterilize them in batches at a low temperature of 60°C. After 1 hour, stand for 24 hours; then sterilize at 60°C for 1 hour, stand for 24 hours, and repeat the sterilization operation 4 times in a row. The sterilized coarse powder is finely pulverized, and then nanometer pulverized, and the pulverized particle size is 50-80nm; finally, the pulverized powder is filled into capsules.

[0058] Another option is to make the above medicines into pills. The specific steps are as follows: select 39 medicinal materials according to the above weights; The 10 herbs of rattan are extracted...

Embodiment 2

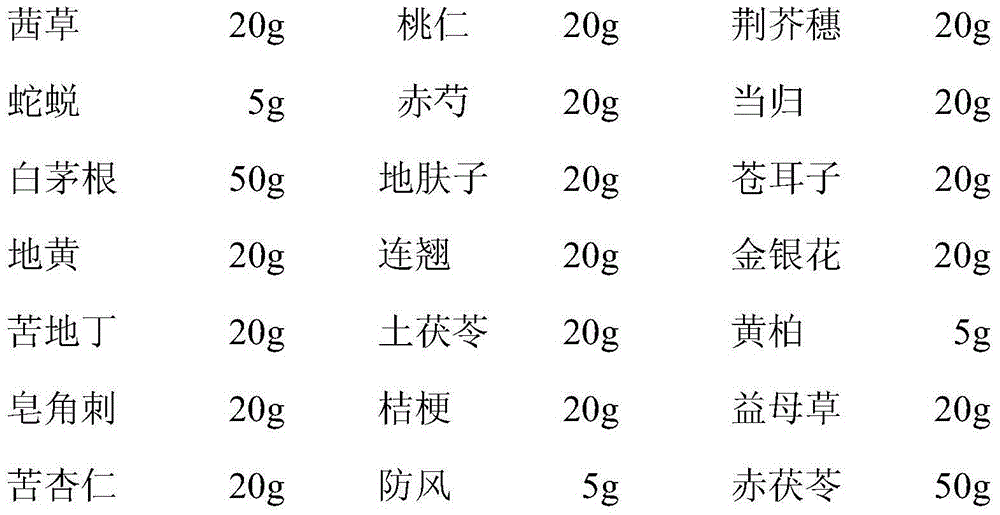

[0060] A medicine for treating skin diseases, comprising raw materials by weight of:

[0061]

[0062]

[0063] The method for preparing the above-mentioned medicine comprises the following steps: first, select 39 medicinal materials according to the above weight, and mix the 39 medicinal materials evenly; then crush the above-mentioned raw materials into coarse powder, place them in an oven, and sterilize them in batches at a low temperature of 60°C. After 1 hour, stand for 24 hours; then sterilize at 60°C for 1 hour, stand for 24 hours, and repeat the sterilization operation 4 times in a row. The sterilized coarse powder is finely pulverized, and then nanometer pulverized, and the pulverized particle size is 50-80nm; finally, the pulverized powder is filled into capsules.

[0064] Another option is to make the above medicines into pills. The specific steps are as follows: select 39 medicinal materials according to the above weights; The 10 herbs of rattan are extracte...

Embodiment 3

[0066] A medicine for treating skin diseases, comprising raw materials by weight of:

[0067]

[0068]

[0069] The method for preparing the above-mentioned medicine comprises the following steps: first, select 39 medicinal materials according to the above weight, and mix the 39 medicinal materials evenly; then crush the above-mentioned raw materials into coarse powder, place them in an oven, and sterilize them in batches at a low temperature of 60°C. After 1 hour, stand for 24 hours; then sterilize at 60°C for 1 hour, stand for 24 hours, and repeat the sterilization operation 4 times in a row. The sterilized coarse powder is finely pulverized, and then nanometer pulverized, and the pulverized particle size is 50-80nm; finally, the pulverized powder is filled into capsules.

[0070] Another option is to make the above medicines into pills. The specific steps are as follows: select 39 medicinal materials according to the above weights; The 10 herbs of rattan are extracte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com