Negative-pressure coating method

A technology of negative pressure and coating surface, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as low efficiency, uneven film thickness, repeated spraying, etc., and achieve improved stability and improved efficiency , Improve the effect of forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

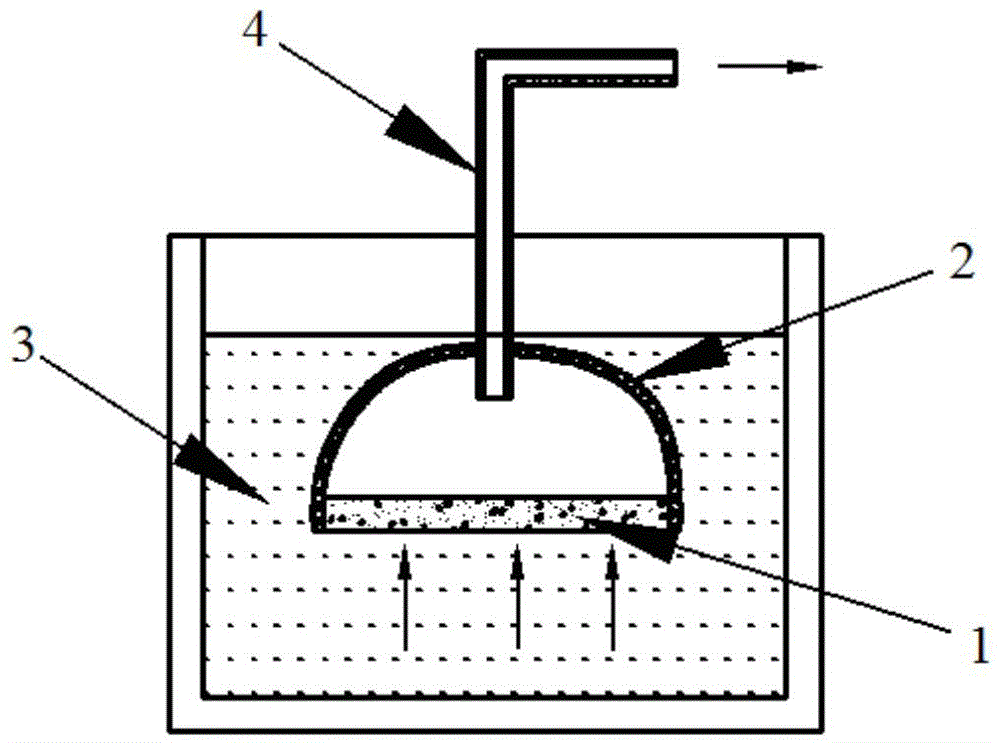

[0023] Such as figure 1 The shown negative pressure coating method of the present invention has a tooling 2 comprising a porous plate-shaped membrane support body 1, the coating surface of the membrane layer support body 1 faces an open space, and the non-coated surface of the membrane layer support body 1 is located in the negative pressure space Among them, the negative pressure space communicates with negative pressure equipment such as a vacuum pump through a pipeline 4 . According to the filtration requirements of the membrane layer, the slurry 3 is configured in a conventional manner. The powder particles in the slurry 3 are spherical, which can better ensure the permeability of the membrane layer and the uniformity of the pore size. At the same time, the particle size of the powder particles in the slurry 3 is about half of the pore diameter on the membrane support 1, and the powder particles of this ratio are more likely to accumulate and block in the pores of the memb...

Embodiment 2

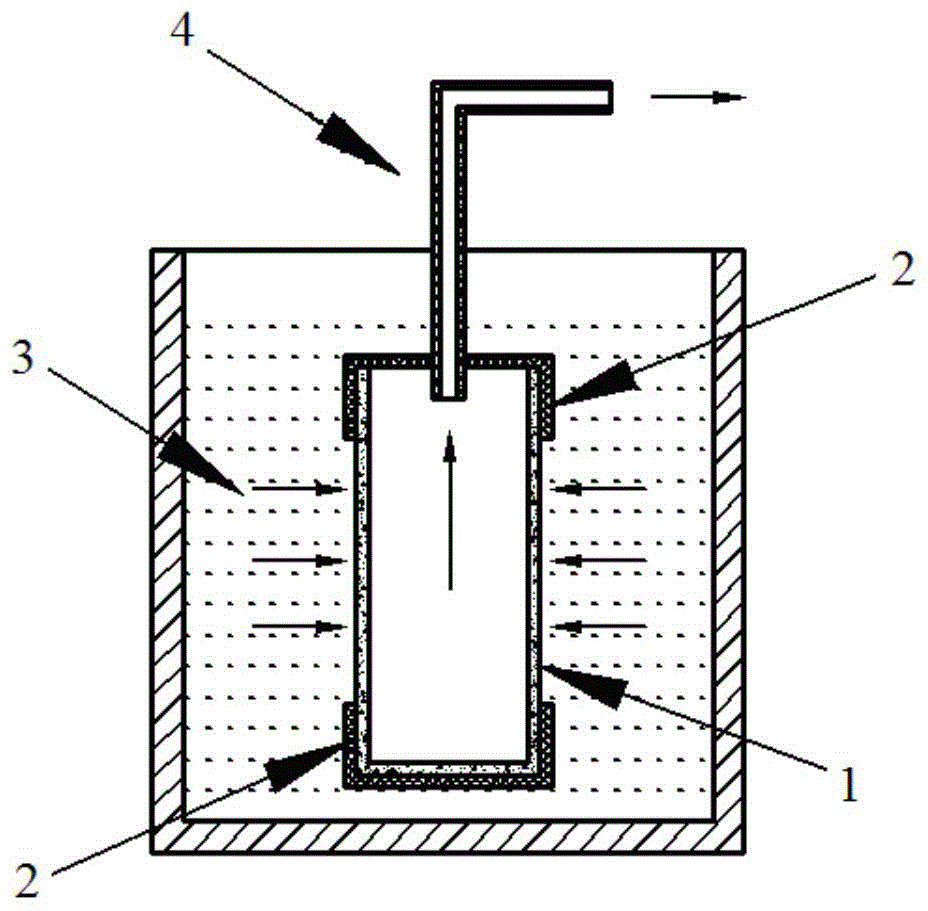

[0026] On the basis of Example 1, the porous tubular membrane layer support 1 is coated. The two ends of the tubular film layer support body 1 are covered with the tooling 2 of the rubber sealing sleeve structure to make it sealed. Then, a through hole is opened on the sealing sleeve at one end to connect the pipeline 4 to the negative pressure equipment, and the inner cavity of the tubular membrane support body 1 is used as a negative pressure space. Place the tooling 2 and the film layer support 1 in the slurry 3 as a whole, open the negative pressure device and pass the pipeline 4 to make the air pressure in the inner cavity of the tubular film support 1 less than the pressure in the slurry 3, and the pressure in the slurry 3 The powder particles uniformly adhere to the outer coating surface of the film layer support 1 under the action of the pressure difference to form a film layer. Finally, the dried and formed membrane layer support body 1 having the membrane layer is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com