Preparation method for CuS/TiO2 core/shell structure nanometer powder

A technology of shell structure and nanopowder, which is applied in the synthesis field of CuS/TiO2 core/shell structure composite nanopowder, to achieve the effect of accelerating preparation efficiency and reducing equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

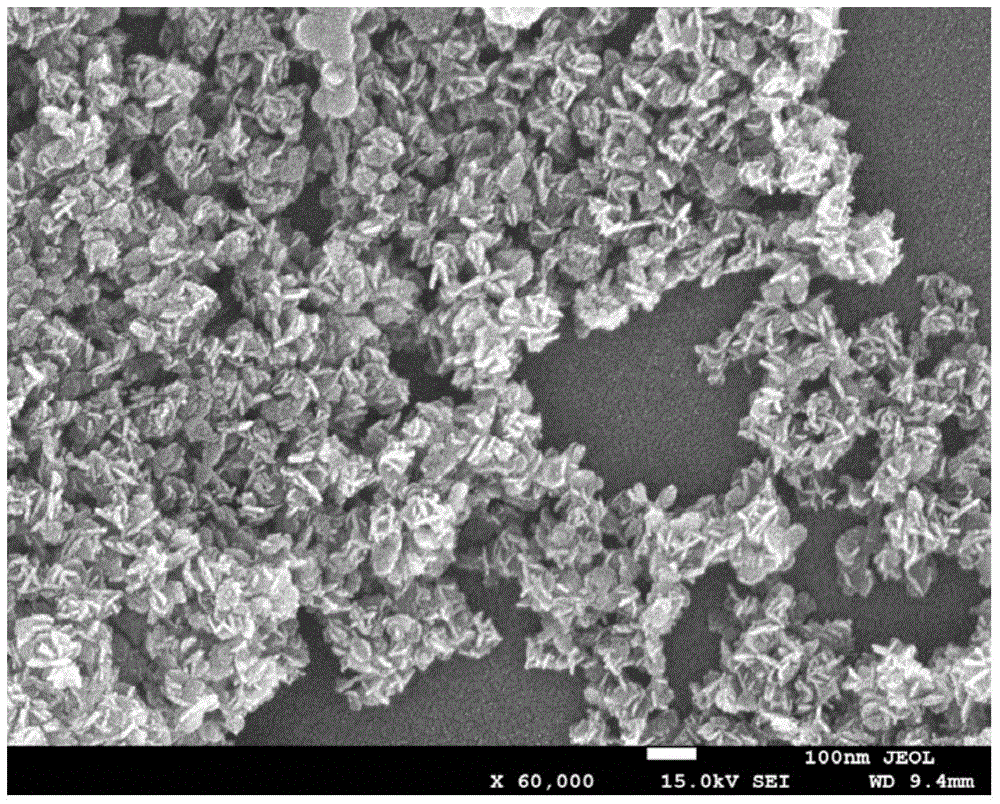

[0040] Variation of core CuS size with reaction time

[0041] By controlling the reaction time within 20min~60min, the size of the core CuS can be changed to a certain extent. The experiment was divided into 4 groups, and the reaction time was 20min, 40min, 60min respectively. The only remaining variable reaction conditions are CuCl 2 The concentration of aqueous solution is 20mmol / L, TiCl 4 The concentration of the ethanol solution is 5% by volume, and the centrifugation speed is 11000r / min. The prepared powder can be observed under a scanning electron microscope with a magnification of 200,000 times, and the size of the core CuS gradually increases between about 10nm and 100nm.

example 2

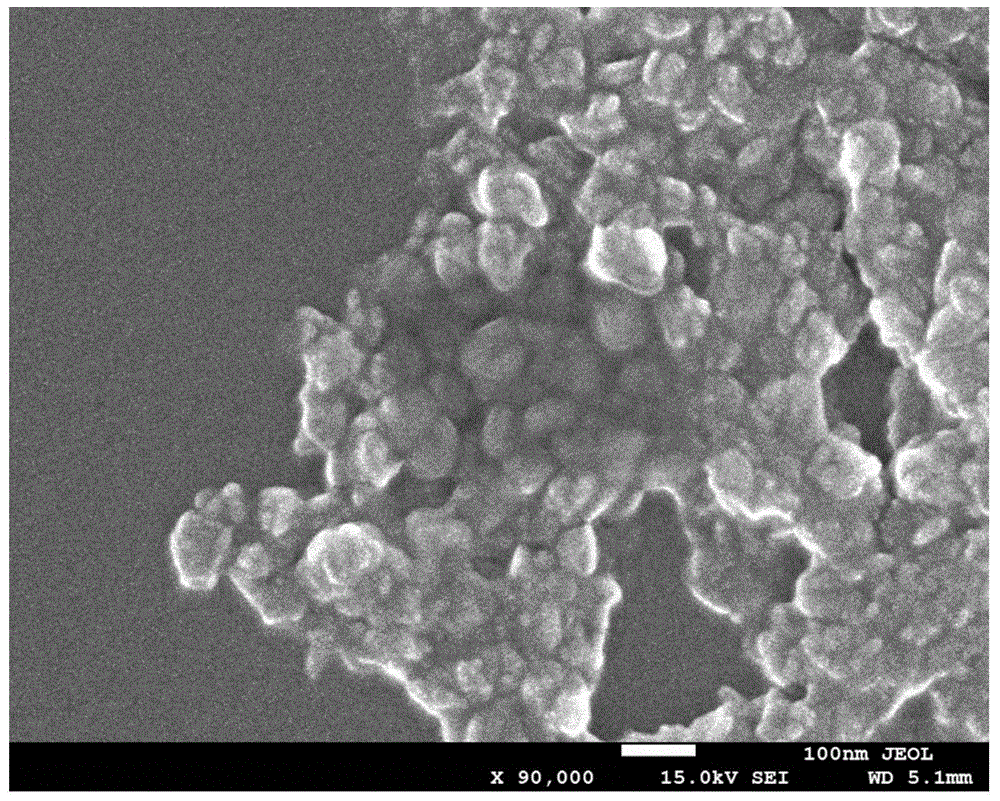

[0043] TiO 2 Coating layer with TiCl 4 Changes in concentration of ethanol solution

[0044] By controlling TiCl 4 The concentration of ethanol solution changes within 3% to 15% by volume, and the coated TiO 2 The thickness of the layers varies to some extent. The experiments were divided into 4 groups, TiCl 4 The concentration of the ethanol solution is 3%, 5%, 10%, and 15% by volume respectively. The only remaining variable reaction conditions are CuCl 2The concentration of the aqueous solution is 20mmol / L, the core reaction time is 30min, and the centrifugal speed is 11000r / min. The prepared powder can be observed under a scanning electron microscope with a magnification of 200,000 times, and the size of the core CuS gradually increases between about 10nm and 100nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com