Automobile steering drive axle

A technology for steering drive axles and automobiles. It is applied in the directions of axles, wheels, brakes, etc. It can solve the problems of easy interference in overall layout, frequent changes of axle housing molds, and long production cycle, and achieve low cost, shortened installation length, and simplified production. The effect of craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

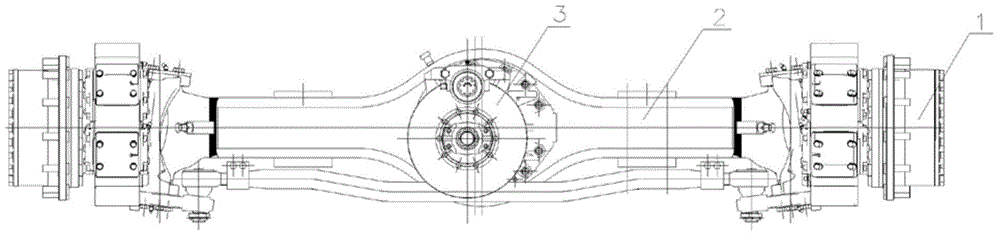

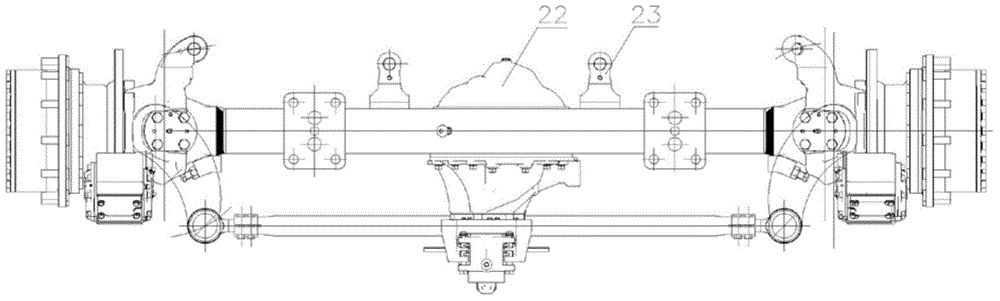

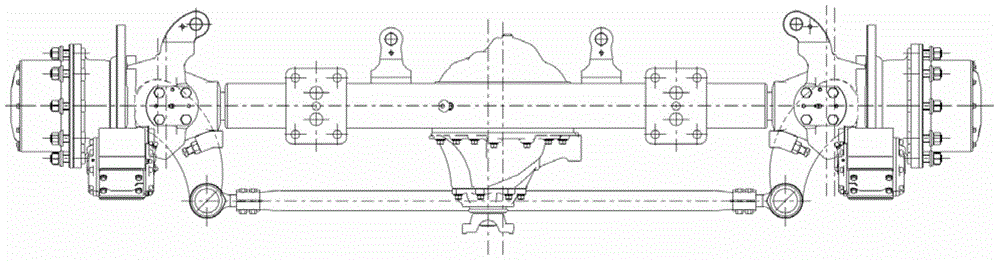

[0036] Such as Figure 1 to Figure 3 As shown, the new large-tonnage steering drive axle for special vehicles of the present invention can meet the severe operating conditions of some special vehicles, including: axle housing assembly 2, final reducer assembly 3 arranged in the middle of the axle housing assembly, And the wheel edge assembly 1 arranged at both ends of the axle housing assembly. The final drive assembly can be integrated with a parking brake (such as figure 2 ), or without a parking brake (eg image 3 shown).

[0037] combine Figure 2 to Figure 4 , the axle housing assembly adopts tailor-welded structure. It includes: four steel plates 21 and a rear cover 22, the four steel plates are respectively welded together to form the axle housing body, the cross section of the axle housing body forms a rectangular cavity, and the rear cover is fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com