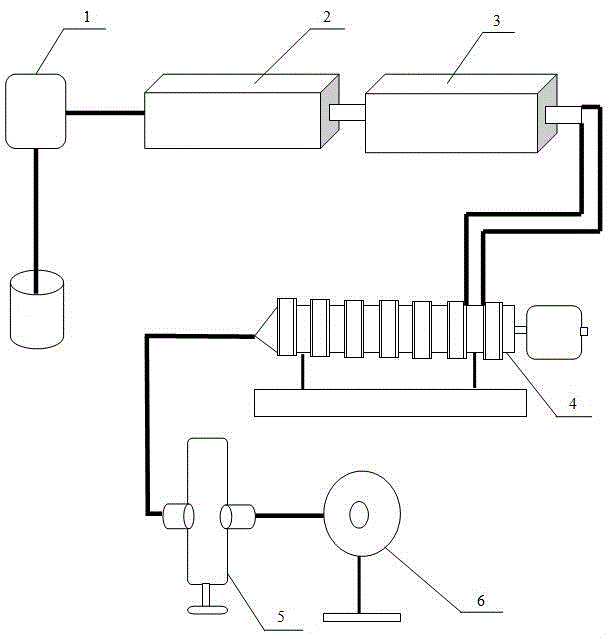

Waste rubber regeneration method and device

A regeneration device and waste rubber technology, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of uneven heating of rubber powder particles, overheating of rubber materials, high efficiency, etc., and achieve high reusable value, low noise pollution, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

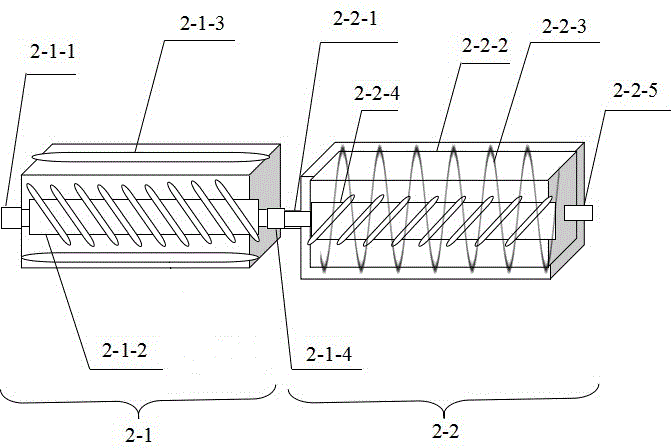

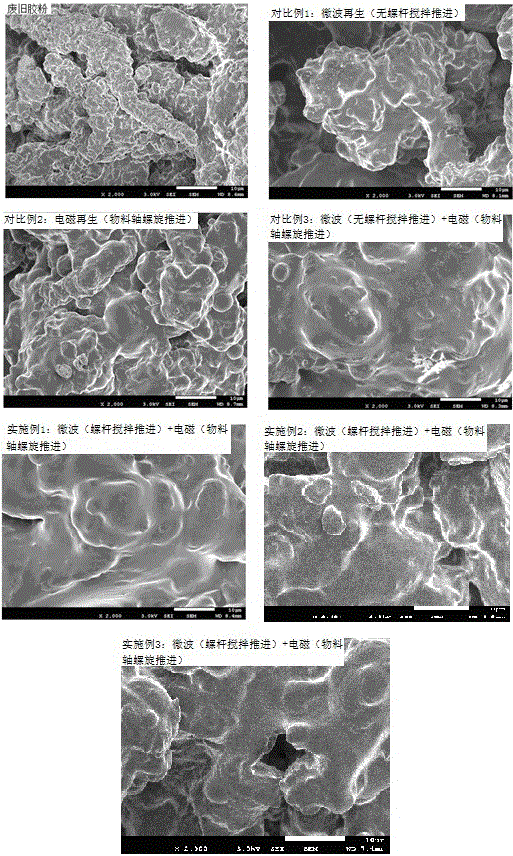

[0028] Example 1: Microwave (screw stirring propulsion) + electromagnetic (material axis spiral propulsion)

[0029] Take 30-40 mesh waste tire whole tire rubber powder as an example. Take the quantitative mixed rubber powder and add it to a microwave desulfurization device through the feeding device, and regenerate it under 2450MHz, 800W microwave radiation, control the temperature between 160-180°C, and control the screw motor speed at 500-900r / min. After desulfurization and regeneration for 6 minutes, it is directly discharged into the feed port of the second-stage electromagnetic desulfurization device through the outlet of the first-stage microwave desulfurization device. The heating power is 2KW, the temperature is controlled between 160-180°C, and the speed of the screw motor is controlled at 500-900r / min. Continue to desulfurize and regenerate for 8 minutes under the same conditions. After the regeneration is completed, the discharge port of the second-stage electro...

Embodiment 2

[0030] Example 2: microwave (screw stirring propulsion) + electromagnetic (material axis spiral propulsion)

[0031] Take 30-40 mesh waste tire whole tire rubber powder as an example. Take the quantitative mixed rubber powder and add it to a microwave desulfurization device through the feeding device, and regenerate it under 2450MHz, 800W microwave radiation, control the temperature between 160-180°C, and control the screw motor speed at 500-900r / min. After desulfurization and regeneration for 5.5 minutes, it is directly discharged into the feed port of the second-stage electromagnetic desulfurization device through the outlet of the first-stage microwave desulfurization device. The heating power is 2KW, the temperature is controlled between 160-180°C, and the speed of the screw motor is controlled at 500-900r / min. Under the conditions, desulfurization and regeneration continued for 8.5 minutes. After the regeneration is completed, the discharge port of the second-stage ele...

Embodiment 3

[0032] Example 3: Microwave (screw stirring propulsion) + electromagnetic (material axis spiral propulsion)

[0033] Take 30-40 mesh waste tire whole tire rubber powder as an example. Take the quantitative mixed rubber powder and add it to a microwave desulfurization device through the feeding device, and regenerate it under 2450MHz, 800W microwave radiation, control the temperature between 160-180°C, and control the screw motor speed at 500-900r / min. Desulfurization and regeneration takes 6.5 minutes, and it is directly discharged into the inlet of the second-stage electromagnetic desulfurization device through the outlet of the first-stage microwave desulfurization device. The heating power is 2KW, the temperature is controlled between 160-180°C, and the speed of the screw motor is controlled at 500-900r / min. Under the conditions, desulfurization and regeneration continued for 7.5 minutes. After the regeneration is completed, the discharge port of the second-stage electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com