Airflow-assisted melt micro-separation centrifugal spinning device and method

A technology of centrifugal spinning and melt differentiation, which is applied in the field of spinning and forming, to achieve the effect of prolonging service life, high mesh surface density and orientation degree, and improving production safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

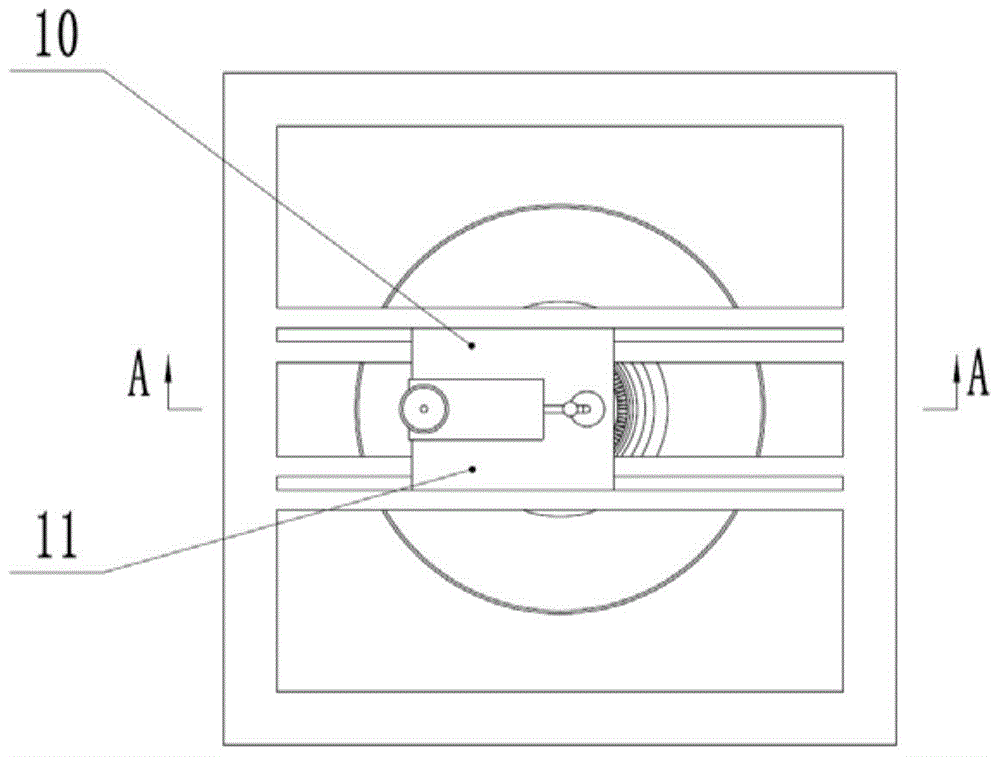

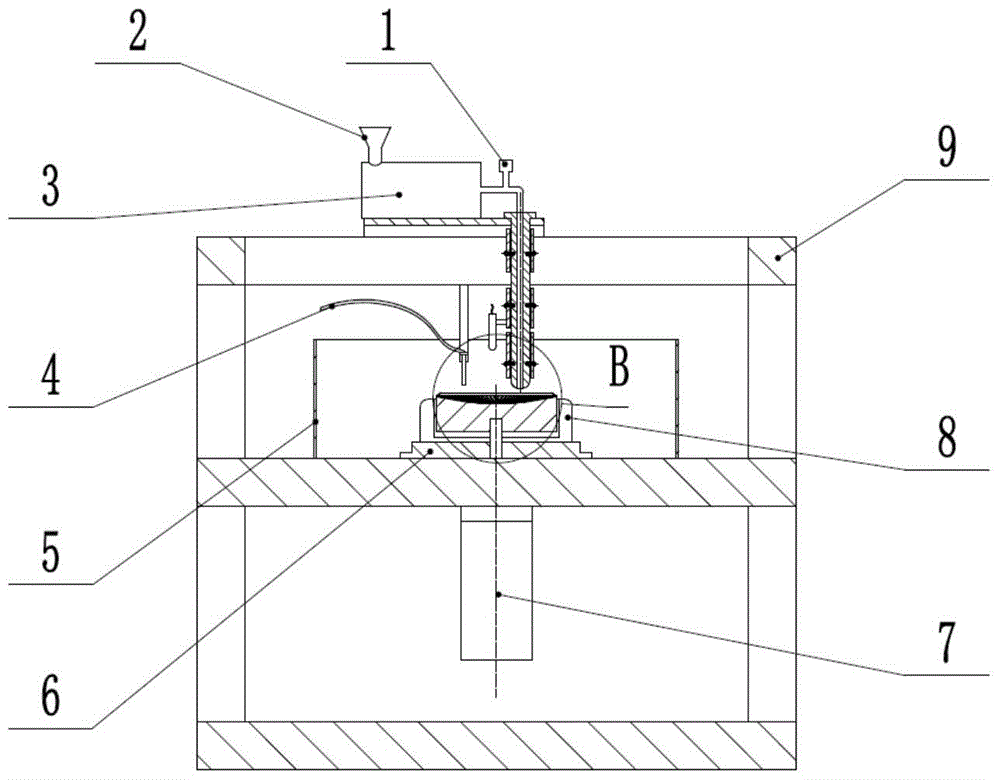

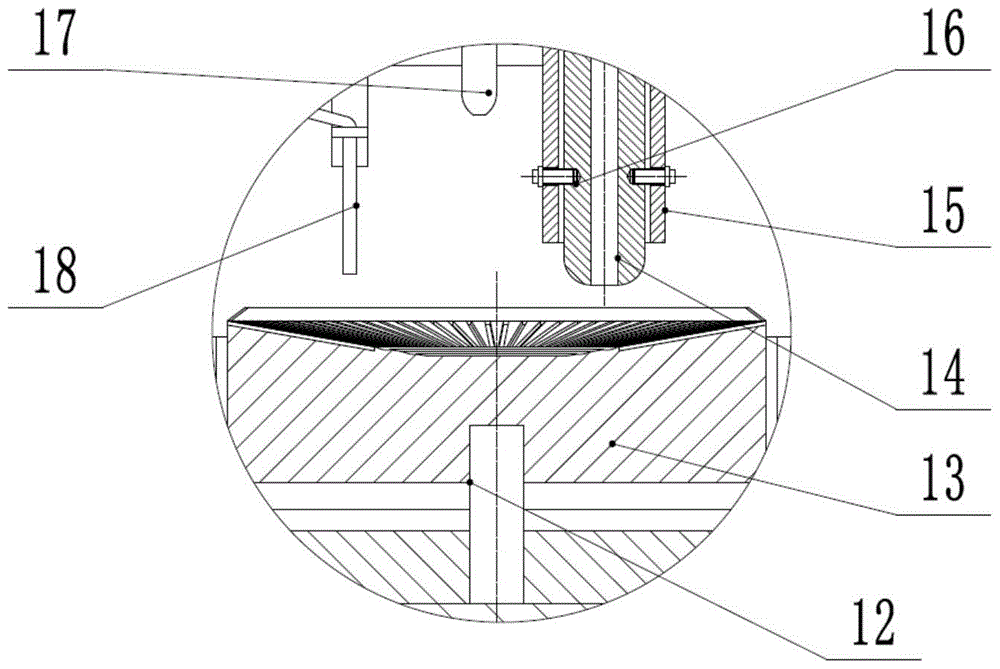

[0017] The present invention proposes an airflow-assisted melt differential centrifugal spinning device, such as Figure 1-3 As shown, it mainly includes: melt metering pump 1, hopper 2, continuous feeding device 3, gas pipe 4, receiving device 5, electromagnetic heating bracket 6, motor 7, electromagnetic heating device 8, spinning box 9, nozzle bracket 10 , slide rail 11, shaft 12, centrifugal differential plate 13, nozzle 14, nozzle heating ring 15, thermocouple 16, infrared thermometer 17 and air pipe support 18, melt metering pump 1, continuous feeding device 3 and nozzle 14 connection , the continuous feeding device 3 and the nozzle 14 are fixed on the nozzle bracket 10 through threaded connection, the nozzle bracket 10 slides on the slide rail 11, the slide rail 11 is welded on the upper part of the box body 9, and the nozzle 14 is at 5 cm above the centrifugal differential plate 12. The eccentric distance from the center line of the centrifugal differential disc 13 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com