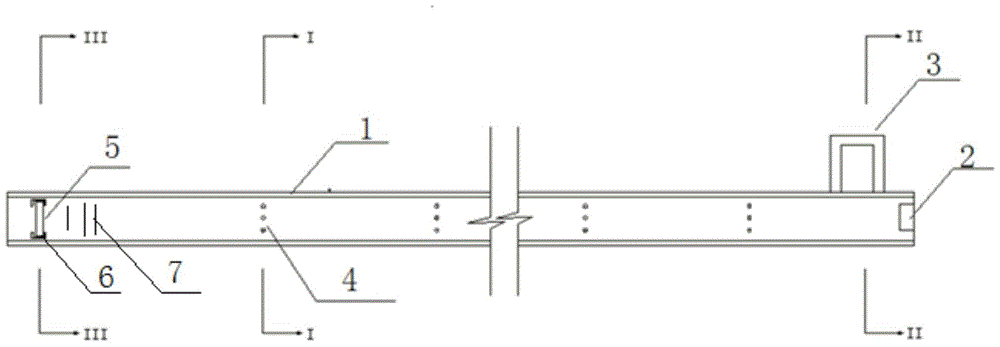

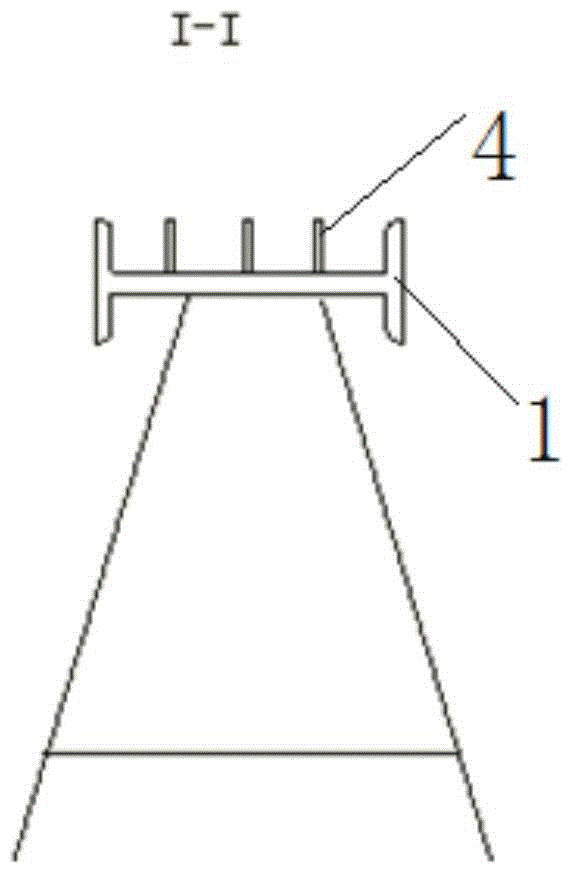

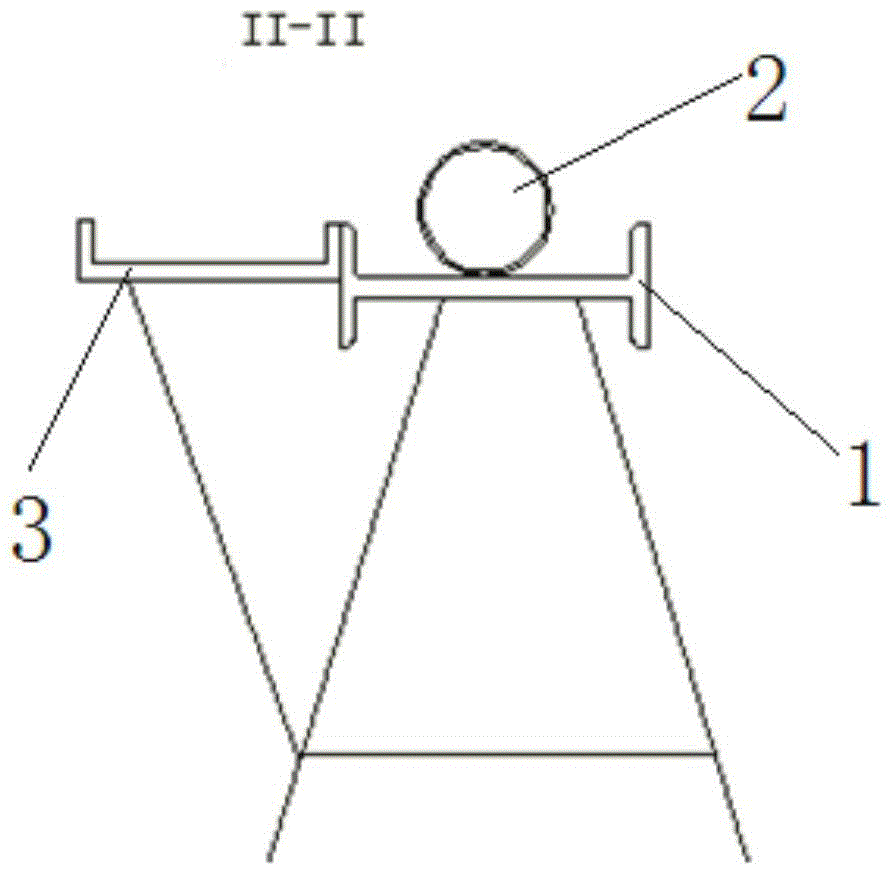

A prestressed steel strand blanking and braiding bench

A technology of prestressed steel strands and benches, which is applied in the erection/assembly of bridges, the processing of building materials, bridges, etc., and can solve the problems of insufficient tension of steel strands, uneven stress on steel strands, and excessive elongation and other problems, to achieve the effect of clear thinking, safe and reliable bench structure, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] Example: In 2013, during the construction of the LH13 contract section of the Linxia-Cooperation Section of the Lanzhou-Langmusi Expressway undertaken by Gansu Road and Bridge Construction Group Co., Ltd., 476 pieces of prestressed beams and slabs were prefabricated in a centralized manner, and the steel strands were cut and bundled Prestressed steel strand blanking and braiding benches are used for construction, which ensures accurate steel strand blanking, steel strands and steel strand bundles are clean, the qualified rate of braiding reaches 100%, and provides convenience for tunnel threading , In this project, the material (prestressed steel strand) was saved by 3%, the labor was saved by 40%, and the work efficiency was increased by 35%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com