A self-operated gas-liquid two-phase liquid level control valve

A control valve, self-operated technology, applied in the field of liquid level control valves, can solve problems such as heavy float, small wall thickness, and insufficient buoyancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

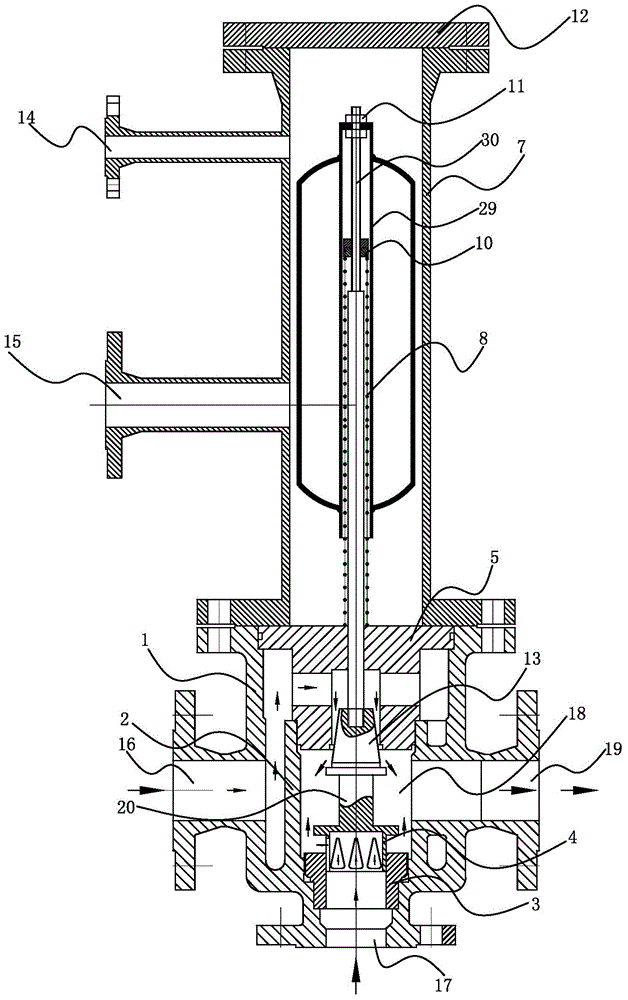

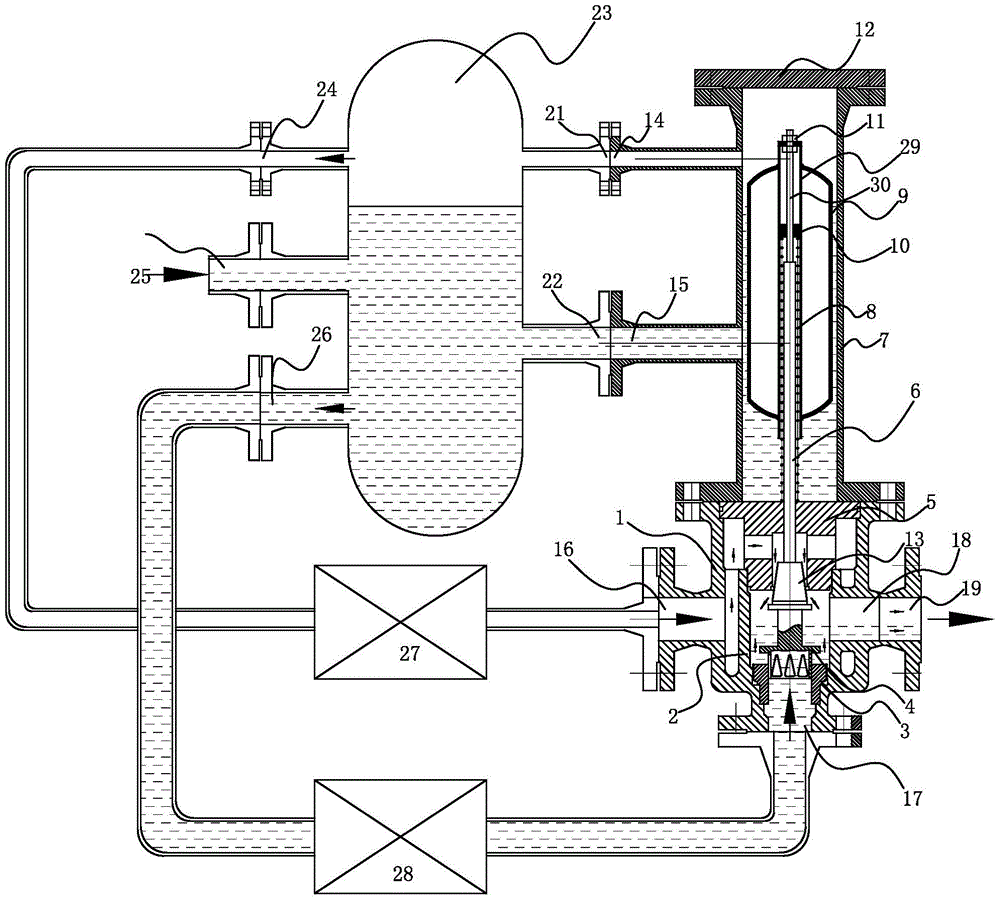

[0030] The following with attached Figure 1 to Figure 2 A self-operated gas-liquid two-phase liquid level control valve of the present invention will be further described in detail.

[0031] A self-operated gas-liquid two-phase liquid level control valve of the present invention, please refer to Figure 1 to Figure 2, comprising a gas-liquid cylinder 7, a valve body, a valve stem 6, a valve core, a float 9, a gas valve seat 5 and a liquid valve seat 3, and the float 9 that can float up and down is located in the sealed gas-liquid cylinder 7, so The valve rod 6 passes through the buoy 9 longitudinally and is fixed in the buoy 9, the bottom end of the valve rod 6 is fixed to the valve core, the gas-liquid cylinder 7 is fixed to the valve body, and the valve rod 6 is fixed to the valve body. The valve body is provided with a gas-liquid mixing outlet 19, the gas valve seat 5 and the liquid valve seat 3 are respectively arranged at the upper and lower positions in the valve body,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com