Helical weld pipe line outer diameter measuring device and method based on view detection

A spiral welded pipe and visual inspection technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of measurement accuracy position calibration and positioning accuracy, measurement results are greatly affected by human factors, and poor automation, etc., to achieve The calibration process is simple and convenient, avoiding the difficulty of position calibration, and the effect of simple and convenient measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

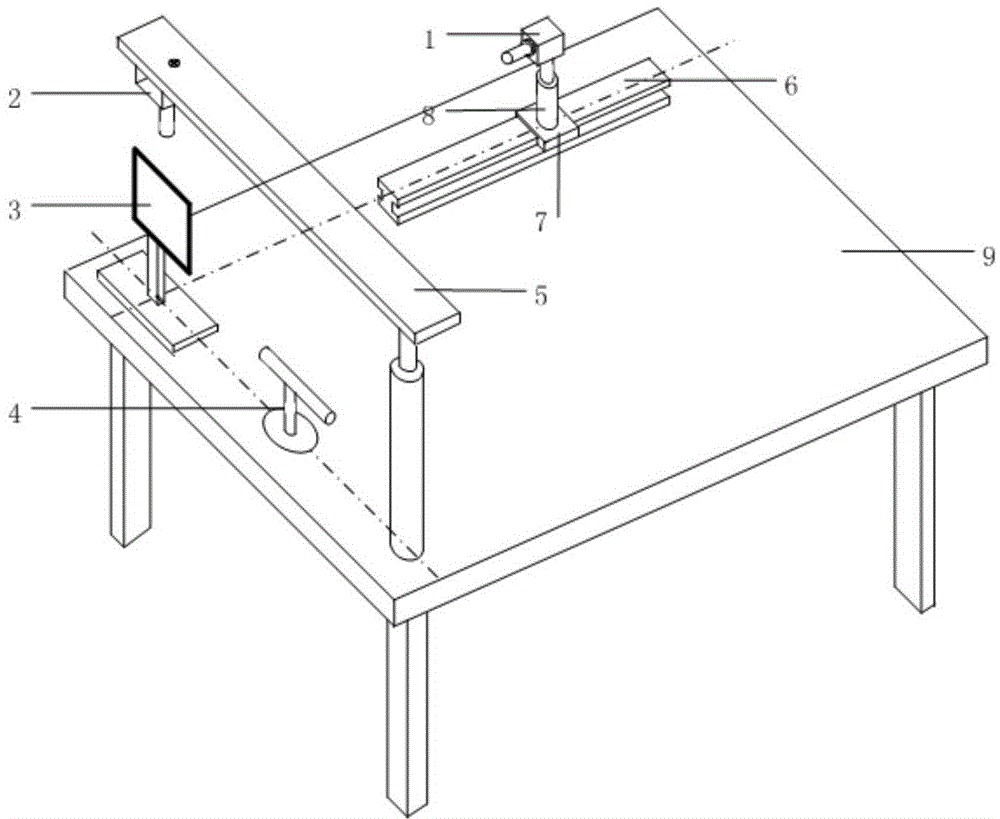

[0037] A device for measuring the outer diameter of a spiral welded pipe line based on visual inspection, including an industrial camera 1, an industrial camera 2, a grid calibration target 3, a line laser generator 4, a cantilever 5, a guide rail 6, a lifting mechanism 8, and a measuring platform 9, and is characterized in that :

[0038]The industrial camera 1, the industrial camera 2, the grid calibration target 3, the line laser generator 4, the cantilever 5, and the guide rail 6 are fixed on the measurement platform 9. The laser plane generated by the line laser generator 4 is perpendicular to the horizontal plane and perpendicular to the direction of the guide rail 6 . The industrial camera 1 is connected with the lifting mechanism 8, and fixed on the slider 7 of the guide rail 6 through the lifting mechanism 8. Its central optical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com