Density measurement system for slurry in wet flue gas desulfurization absorption tower of thermal power plant

A technology for wet flue gas desulfurization and thermal power plants. It is applied to determine the direction of specific gravity by measuring the pressure difference. It can solve problems such as measurement errors and affecting the operation of the desulfurization system, and achieve overall investment reduction, corrosion hazard removal, and simple algorithms. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

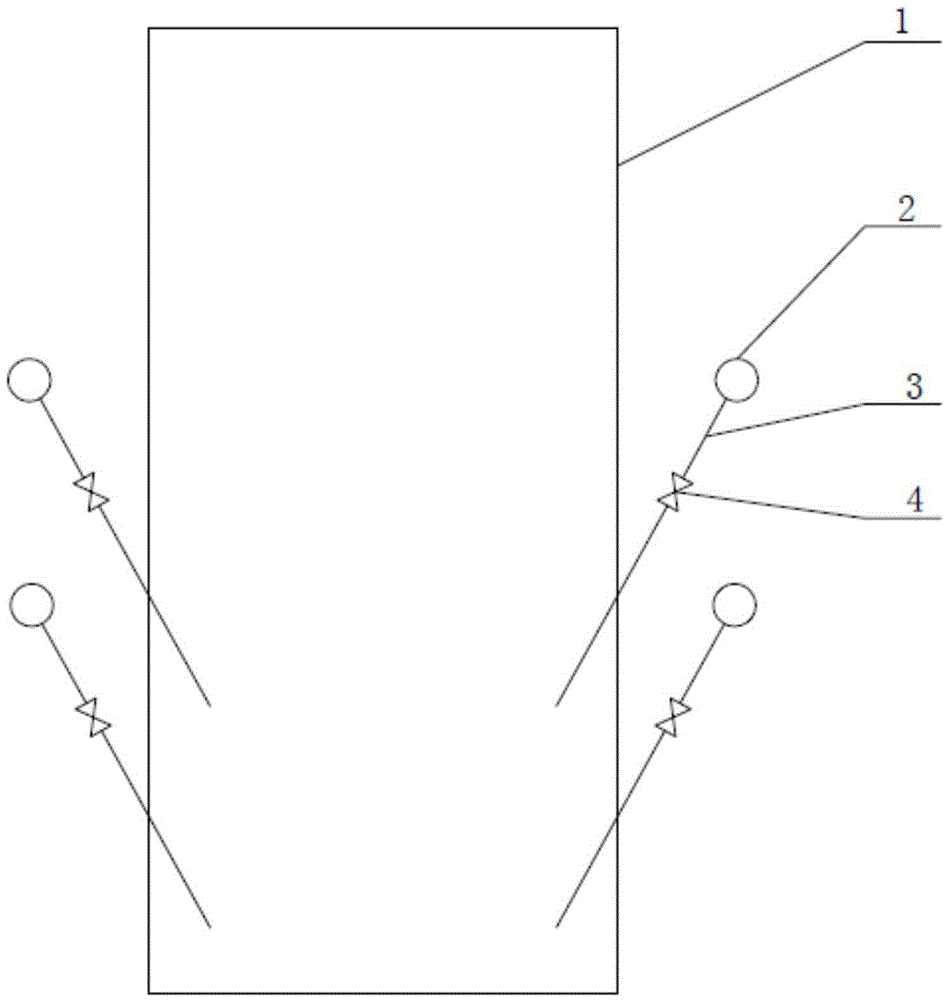

[0014] Such as figure 1 As shown, it is a structural schematic diagram of a slurry density measurement system in a wet flue gas desulfurization absorption tower of a thermal power plant according to the present invention. The present invention includes a controller and two sets of measuring mechanisms. on the desulfurization absorption tower 1. The differential pressure measurement method is used to directly measure the density of the slurry in the desulfurization absorption tower 1.

[0015] The measuring mechanism includes two pressure transmitters 2 and two sampling tubes 3 arranged at intervals in the vertical direction outside the desulfurization absorption tower 1; one end of each sampling tube 3 is connected to the desulfurization absorption tower 1, and the other end is connected to the corresponding The connection port of the pressure transmitter 2 is connected, and a manual valve 4 is provided on each sampling pipe 3; the two pressure transmitters 2 in each group of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com