Six-freedom-degree parallel platform in driving orthogonal arrangement

An orthogonal layout and degree of freedom technology, applied in the direction of electrical program control, digital control, etc., can solve the problems of increasing the difficulty of system assembly, precision requirements and manufacturing costs, high manufacturing and maintenance costs, and difficult decoupling calculations, so as to improve the system Rigidity and dynamic response characteristics, reduced manufacturing costs and maintenance costs, and simplified decoupling calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing.

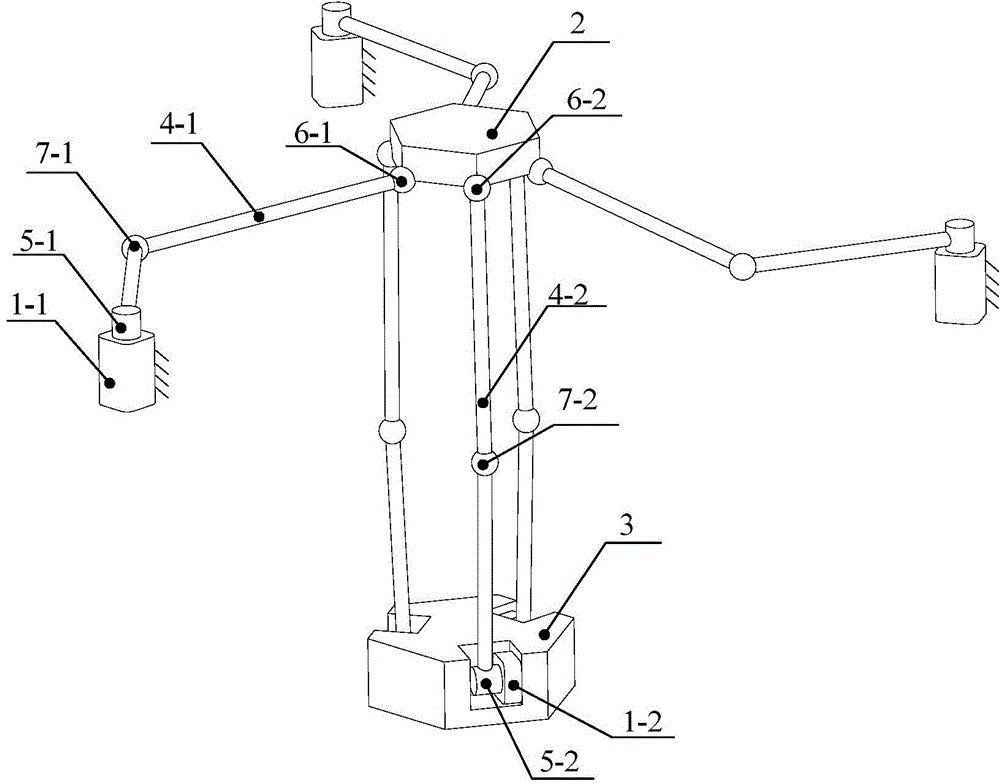

[0011] Such as figure 1 As shown, a six-degree-of-freedom parallel platform driven in an orthogonal arrangement includes a driving motor, a moving platform 2, a fixed base 3 and a connecting rod branch chain. There are 6 driving motors in total, which are divided into the first group of driving motors 1-1 and the second group of driving motors 1-2, each group of driving motors has three driving motors; the first group of driving motors 1-1 and the second group of driving motors 1-2 are fixed in two parallel planes , each group of driving motors is center-symmetrically distributed in their respective fixed planes; the axes of the first output shafts 5-1 of the first group of driving motors 1-1 are parallel to each other but not coplanar, and the axes of the second group of driving motors 1-2 The axis of the second output shaft 5-2 is in the same plane, the axis of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com