A multi-touch screen based on frustrated total internal reflection technology and its method for identifying multi-touch

A suppressed total internal reflection, multi-touch screen technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc. Touch screen system weight and other issues, to achieve the effect of reducing after-sales maintenance costs, easy production and maintenance, and good anti-light interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

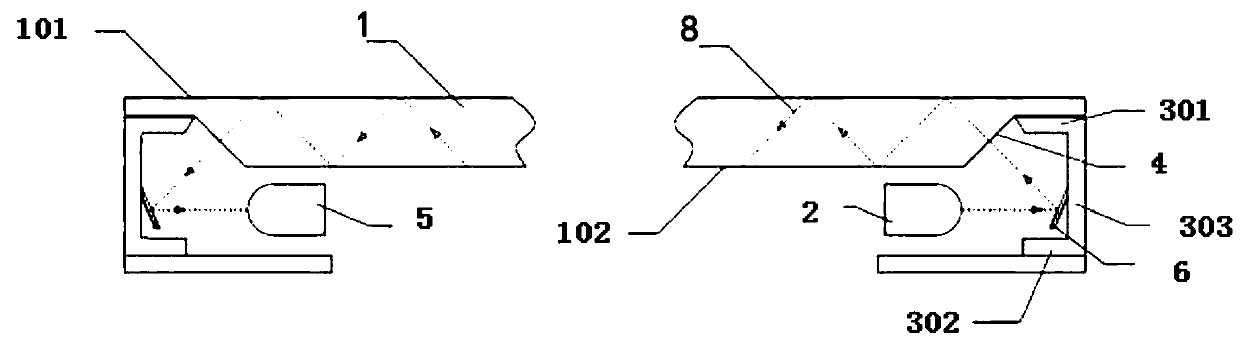

[0034] Such as figure 1 As shown, the infrared emitting tube is used as the light source 2, and the infrared receiving tube is used as the light receiver 5. Optical glass (refractive index about 1.52) is used as the touch screen substrate 1, according to the formula n 1 sinθ 1 =n 2 Calculate the minimum incident angle, select the slope 4 with an angle greater than 45°, and perform polishing. The infrared emitting tube emits infrared light which is reflected by the mirror 6 and then perpendicular to the non-touch surface 102 of the touch screen substrate 1 and enters the touch screen substrate 1 to form total internal reflection. The horizontal angle between the mirror 6 and the touch screen substrate 1 is about 112° to ensure that the infrared light can be projected perpendicular to the non-touch surface 1023 of the touch screen substrate 1 . Infrared light is transmitted in the touch screen substrate 1 by total reflection, forms an infrared light network on the touch surf...

example 2

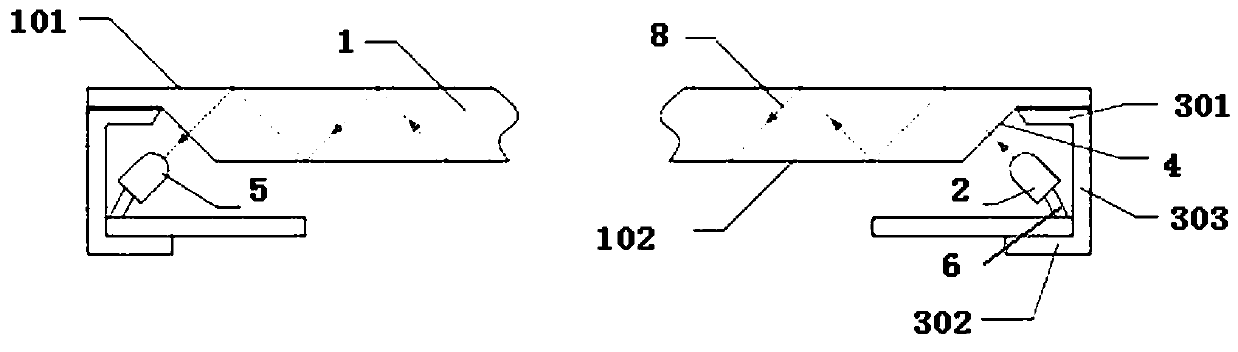

[0038] Such as figure 2 As shown, the present embodiment is further coupled based on Embodiment 1, and the infrared emitting tube and the reflector 6 are coupled together to form the light source 2, and the infrared receiving tube and the reflector 6 are coupled together to form the light receiver 5; the light source 2 The emitted infrared light is perpendicular to the non-touch surface 102 of the touch screen substrate 1 and enters the touch screen substrate 1 to form total internal reflection transmission. The non-touch surface 102 of the touch screen substrate 1 forms an angle of 45° with the horizontal plane and is polished. Infrared light is transmitted in the touch screen substrate 1 by total reflection, forms an infrared light network on the touch surface 101 of the touch screen substrate 1, and is transmitted to the light receiver 5 through the non-touch surface 102 of the touch screen substrate 1 at the corresponding end of the touch screen substrate 1, Thus forming...

example 3

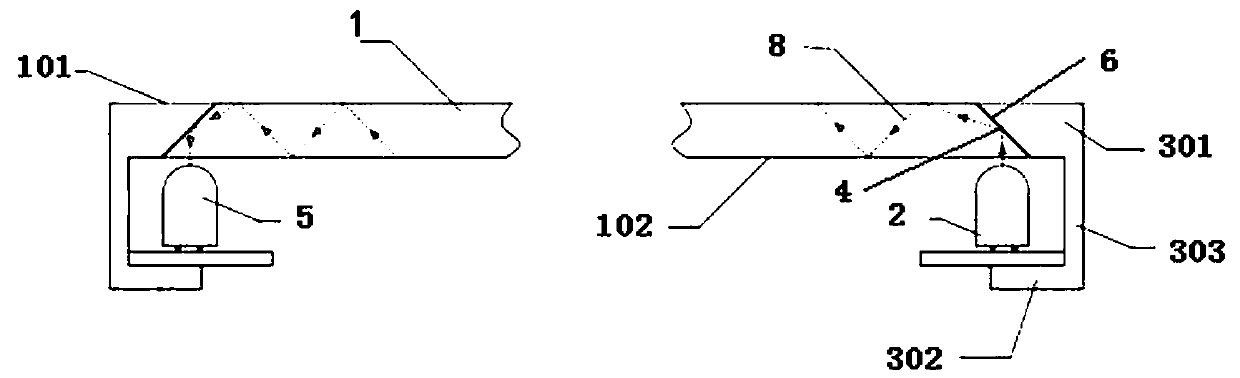

[0040] In this embodiment, the mirror 6 is used as a light guide component to transmit the optical signal 8 into the substrate to form total internal reflection. Such as image 3As shown, the non-touch surface 102 of the touch screen substrate 1 forms an angle greater than 113° with the horizontal plane and is mirror-coated to form a reflective mirror 6. The infrared reflection tube emits infrared light perpendicular to the touch screen substrate 1 and passes through the non-touch surface 102 of the touch screen substrate 1. After reflection, it enters the touch screen substrate 1 to form total internal reflection. Infrared light is transmitted in the touch screen substrate 1 by total reflection, forms an infrared light network on the touch surface 101 of the touch screen substrate 1, and is transmitted to the The optical receiver 5 forms a complete transmitting and receiving system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com