Contact debris flow motion parameter monitoring device and system as well as debris flow early-warning method

A technology for monitoring devices and motion parameters, which is applied in the field of disaster monitoring and debris flow prevention and control engineering, and can solve problems such as complex technical means, difficult application, high false alarm rate, and high false alarm rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

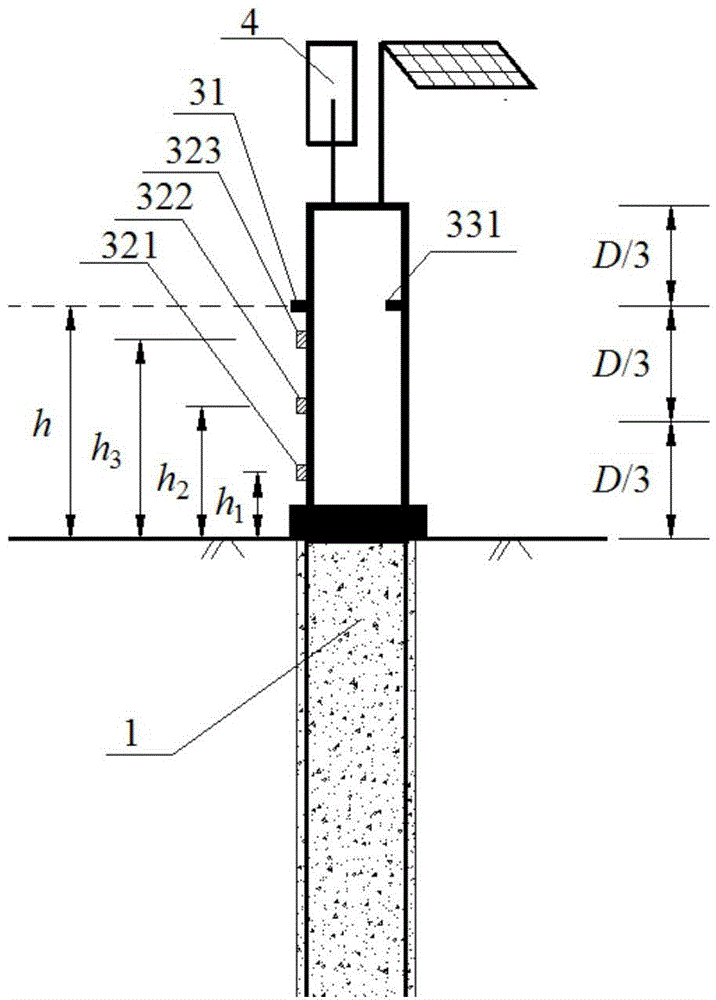

[0068] like Figure 1-1~Figure 1-2 As shown in Fig. 1, a contact-type debris flow movement parameter monitoring device is manufactured, which is used in a disaster prevention and control project of a debris flow channel A.

[0069] According to on-site investigation and investigation, the debris flow formation area, circulation area, and hazard area in the ditch are divided, and the thickness of the loose accumulation body in the ditch is determined to be 10m, and the maximum mud depth in the ditch is D=3m. Channel area 25Km 2, the length of the main groove is 8Km, and the average width of the channel in the circulation area is B=40m.

[0070] Picture 1-1 It is a schematic diagram of the overall structure of the contact debris flow movement parameter monitoring device. The main structure of the contact debris flow movement parameter monitoring device is a columnar monitoring pile 1, and the lower part of the columnar monitoring pile 1 is made of micro-steel pipe piles, spec...

Embodiment 2

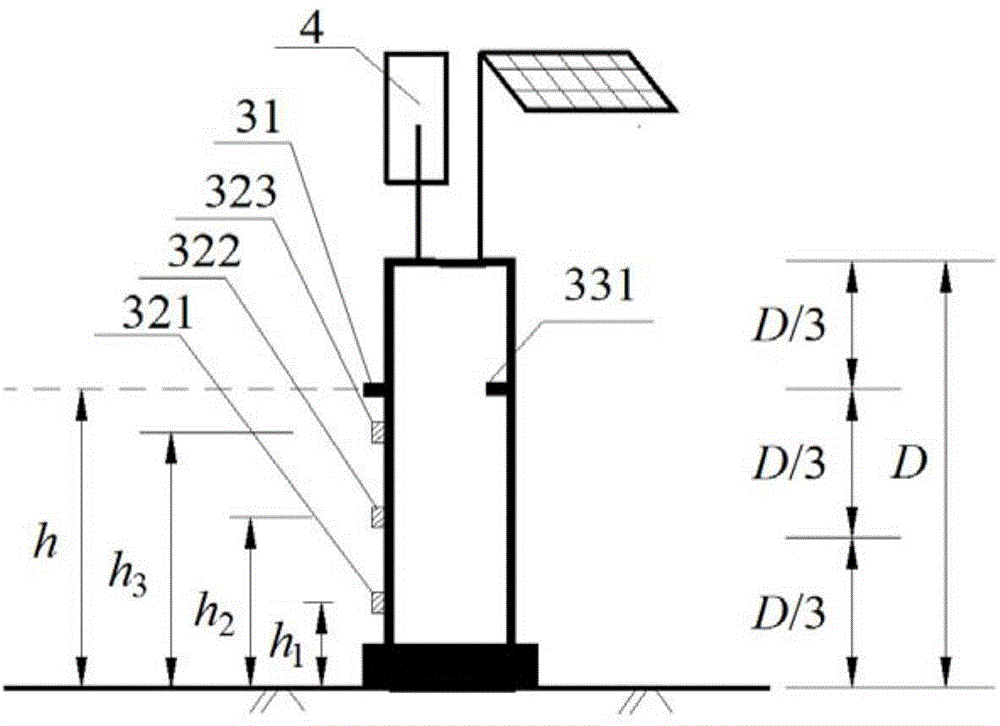

[0079] like Figure 2-1 to Figure 2-4 As shown, based on the contact-type debris flow movement parameter monitoring device processed in Example 1, a contact-type debris flow movement parameter monitoring system is further arranged in the debris flow channel A.

[0080] Figure 2-1 It is a schematic diagram of the structure of the contact debris flow movement parameter monitoring system. The monitoring system includes a contact monitoring device for debris flow movement parameters and an upper control center 5 . The contact debris flow movement parameter monitoring device also includes a signal transmission device 4 connected to the signal acquisition device 2; the signal transmission device 4 communicates with the upper control center 5 through wireless signals.

[0081] Figure 2-2 It is a schematic diagram of the side section of the arrangement of the contact debris flow movement parameter monitoring device. The contact monitoring devices for debris flow movement paramet...

Embodiment 3

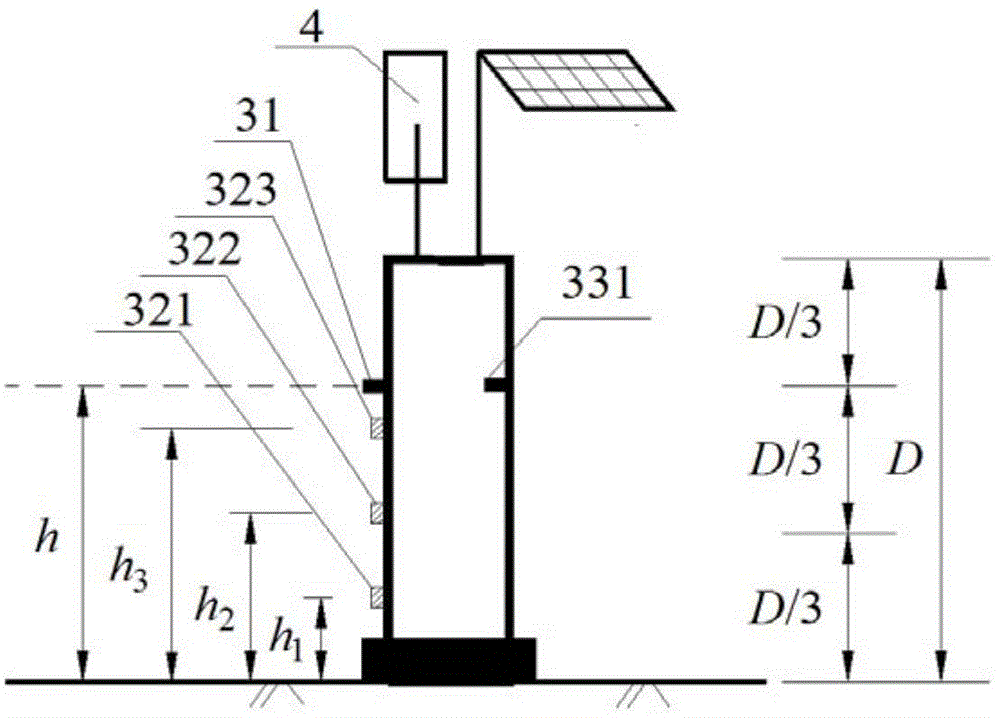

[0084] like Figure 3-1~Figure 3-2 As shown, a contact monitoring system for debris flow movement parameters is arranged in debris flow channel B.

[0085] According to the field investigation and investigation, the debris flow formation area, circulation area, and hazard area in the trench are divided, and the thickness of the loose accumulation body in the trench is determined to be 8m, and the maximum mud depth in the trench is D = 2.7m. Channel area = 50Km 2 , the length of the main channel = 15Km, the average channel width B in the circulation area = 120m.

[0086] The processing contact type debris flow movement parameter monitoring device, which is the same as the first embodiment will not be repeated, the difference is h 1 = 0.4m, h 2 = 1.4m, h 3 =2.4m,

[0087] Figure 3-1 It is a top view schematic diagram of the arrangement of contact debris flow movement parameter monitoring devices, Figure 3-2 Yes Figure 3-1 A-A cross-sectional schematic diagram. Arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com