Surface-adhered type over-current protection element and manufacturing method

A technology for protecting components and overcurrent, which is applied in the direction of resistance manufacturing, electrical components, resistor components, etc., and can solve the problems of reducing heat transfer and heat transfer of overcurrent protection components, unfavorable overcurrent protection components to maintain current carrying current, etc. , achieve the effect of doubling the holding current, easy heat conduction and heat dissipation, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

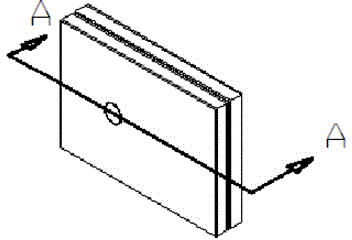

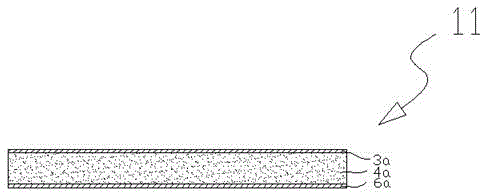

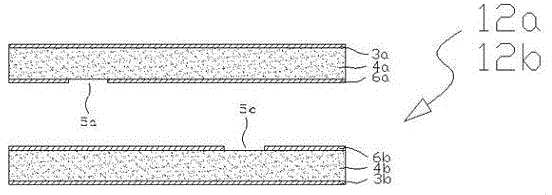

[0044] Such as figure 1 The three-dimensional view of the basic structure overcurrent protection element, figure 2 forfigure 1 A-A sectional view of and Figure 7 As shown in the cross-sectional view of the finished overcurrent protection component, a surface mount overcurrent protection component consists of:

[0045] 1) Two conductive composite material chips with a positive temperature coefficient of resistance effect stacked on the upper and lower structures, and metal pins 1 are welded on the protection element, where:

[0046] The upper chip a includes:

[0047] (a) an upper conductive composite base layer 4a having a positive temperature coefficient of resistance effect, having upper and lower surfaces;

[0048] (b) The first conductive electrode 3a is placed on the upper surface of the upper conductive composite material base;

[0049] (c) The second conductive electrode 6a is placed on the lower surface of the upper conductive composite material base;

[0050] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com