Interior wall thermal insulation coating material and preparation method thereof

A technology for thermal insulation coatings and interior walls, applied in reflective/signal coatings, antifouling/underwater coatings, coatings, etc., to solve the problems of single function and insufficient adhesion of interior wall thermal insulation coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

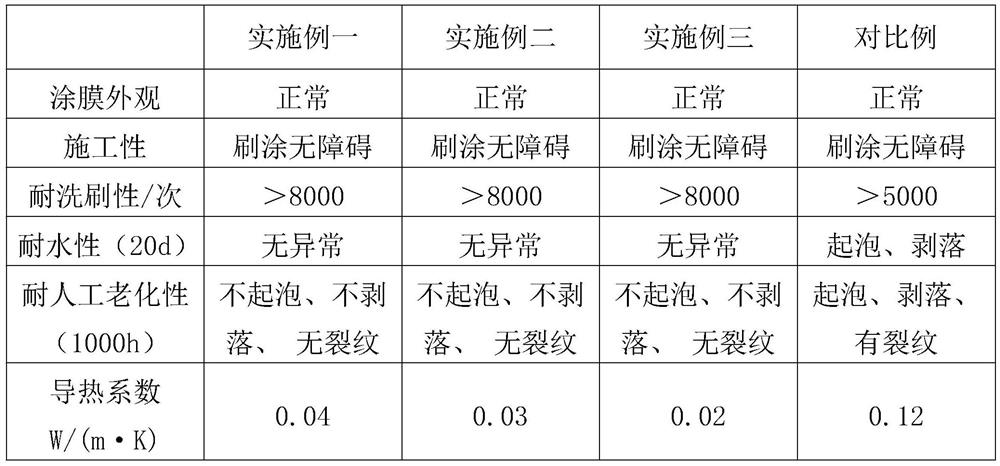

Examples

Embodiment 1

[0021] A thermal insulation coating for interior walls, comprising the following components in parts by weight: 30 parts of modified styrene-acrylic emulsion, 15 parts of silicon-acrylic emulsion, 5 parts of aluminum dihydrogen phosphate, 10 parts of hollow ceramic microspheres, 5 parts of aluminum silicate fiber, 3 parts of graphene, 4 parts of diatomite, 3 parts of zirconium silicate, 2 parts of tourmaline powder, 1 part of medical stone, 0.8 parts of silane coupling agent KH-5500, acrylate block polymer dispersant (Yangzhou Tianda Chemical Co., Ltd. Co., Ltd.) 1 part, 0.5 parts of sodium carboxymethyl cellulose, 0.5 parts of silicone defoamer, 0.4 parts of Casson, 18 parts of water;

[0022] The synthetic method of described modified styrene-acrylic emulsion is: (1) take the raw material of each weight part respectively for standby, and described raw material comprises 20 parts of styrene, 30 parts of ethyl acrylate, 0.4 part of ammonium persulfate, lauryl 0.6 parts of sodi...

Embodiment 2

[0027] An interior wall thermal insulation coating, comprising the following components in parts by weight: 35 parts of modified styrene-acrylic emulsion, 22 parts of silicon-acrylic emulsion, 8 parts of aluminum dihydrogen phosphate, 14 parts of hollow ceramic microspheres, 6 parts of aluminum silicate fiber, 5 parts of graphene, 6 parts of diatomaceous earth, 4 parts of zirconium silicate, 4 parts of tourmaline powder, 2 parts of medical stone, 1.5 parts of silane coupling agent KH-560, 2 parts of sodium polyacrylate, 0.8 parts of polyacrylamide, poly Ether defoamer (produced by Hengxin Chemical Technology Co., Ltd., model THI X-288) 0.8 parts, 1,2-benzisothiazolin-3-one 0.6 parts, water 25 parts;

[0028] The synthetic method of described modified styrene-acrylic emulsion is: (1) take the raw material of each weight part respectively for standby, and described raw material comprises styrene 23 parts, ethyl acrylate 34 parts, ammonium persulfate 0.5 part, lauryl 1 part of so...

Embodiment 3

[0033] An interior wall thermal insulation coating, comprising the following components in parts by weight: 40 parts of modified styrene-acrylic emulsion, 30 parts of silicon-acrylic emulsion, 10 parts of aluminum dihydrogen phosphate, 18 parts of hollow ceramic microspheres, 9 parts of aluminum silicate fiber, 6 parts of graphene, 8 parts of diatomaceous earth, 6 parts of zirconium silicate, 5 parts of tourmaline powder, 4 parts of medical stone, 2 parts of silane coupling agent KH-5702, 3 parts of ammonium polyacrylate, polyurethane associative thickener 1.2 parts, 1 part of silicone defoamer, 0.5 parts of Cathone, 0.3 parts of 1,2-benzisothiazolin-3-one, 32 parts of water;

[0034] The synthetic method of described modified styrene-acrylic emulsion is: (1) take the raw material of each weight part respectively for standby, and described raw material comprises styrene 25 parts, ethyl acrylate 38 parts, ammonium persulfate 0.6 part, lauryl 1 part of sodium sulfate, 1.5 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com