Wiring board and method for mounting semiconductor element on wiring board

A technology of a wiring substrate and a mounting method, which is applied in the direction of semiconductor devices, semiconductor/solid-state device components, and electrical components to assemble printed circuits, can solve problems such as the S' mounting of semiconductor components, and achieve the effect of high connection reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

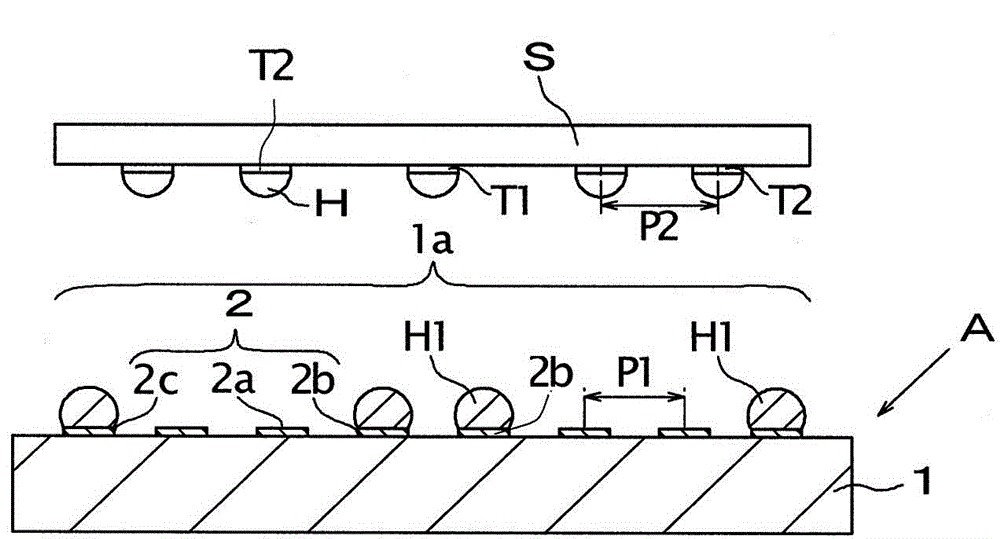

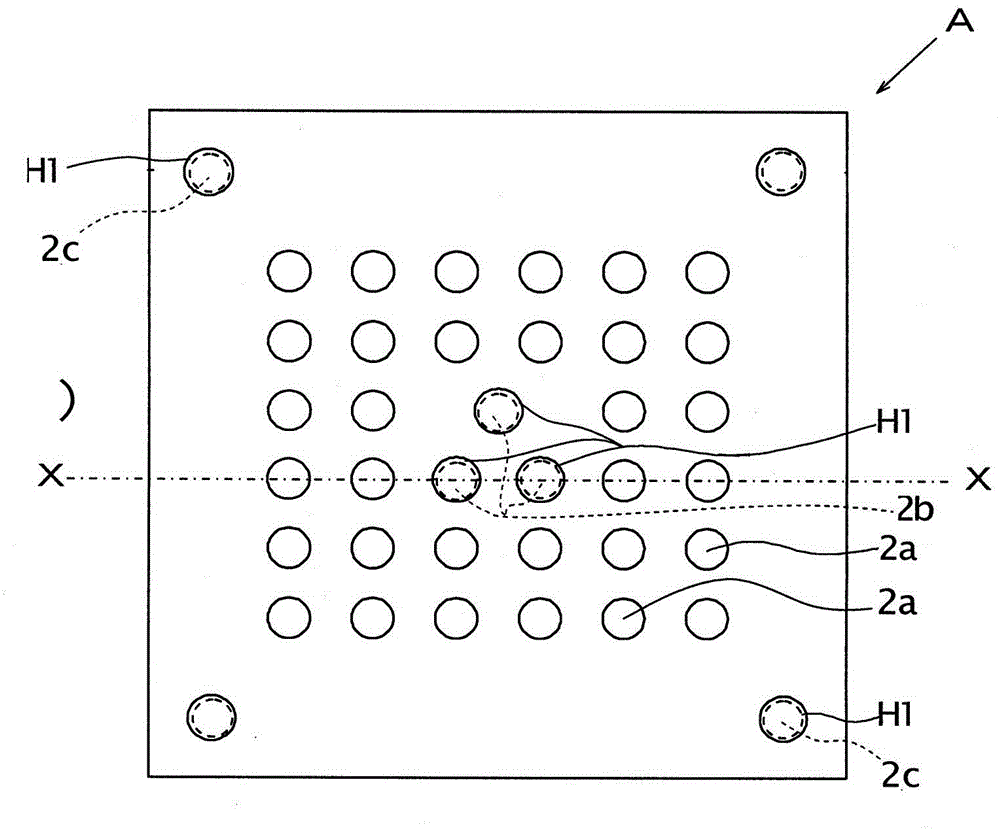

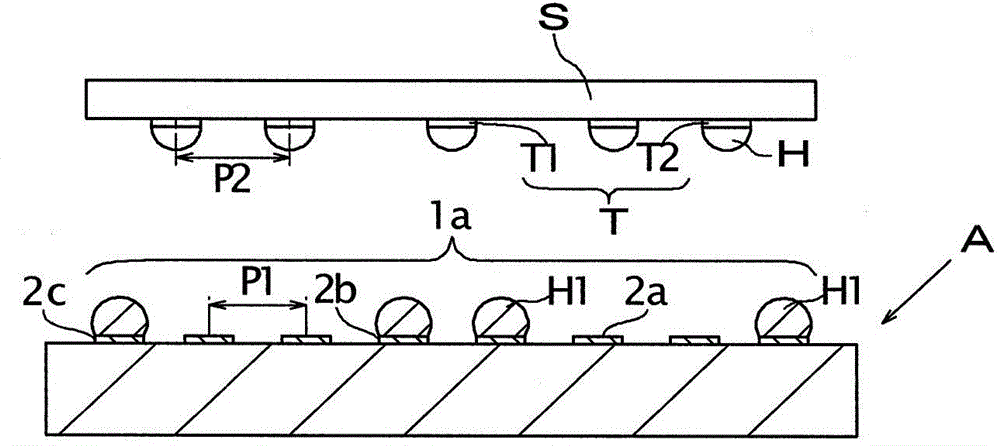

[0023] Next, based on Figure 1A as well as Figure 1B One embodiment of the wiring board of the present invention will be described. in addition, Figure 1A yes Figure 1B The X-X line profile shown. Such as Figure 1A As shown, the wiring board A of the present invention mainly includes an insulating substrate 1 and pads 2 .

[0024] The insulating substrate 1 is formed of, for example, an electrically insulating material obtained by impregnating a glass cloth with a thermosetting resin such as epoxy resin or bismaleimide triazine resin. The insulating substrate 1 has a mounting portion 1a on which a semiconductor element S is mounted on its upper surface. Figure 1A The illustrated insulating substrate 1 has a single-layer structure, but may also have a multi-layer structure in which a plurality of insulating layers made of the same or different electrically insulating materials are laminated. The semiconductor element S has a first electrode terminal T1 at the center of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com