Device used for interfacial polymerization process and membrane performance testing and operation method thereof

An interfacial polymerization and membrane technology, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of immature interfacial polymerization device design, cumbersome operation steps, and increased preparation cost, and achieve high-efficiency interfacial polymerization. Craftsmanship, practical and convenient, beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

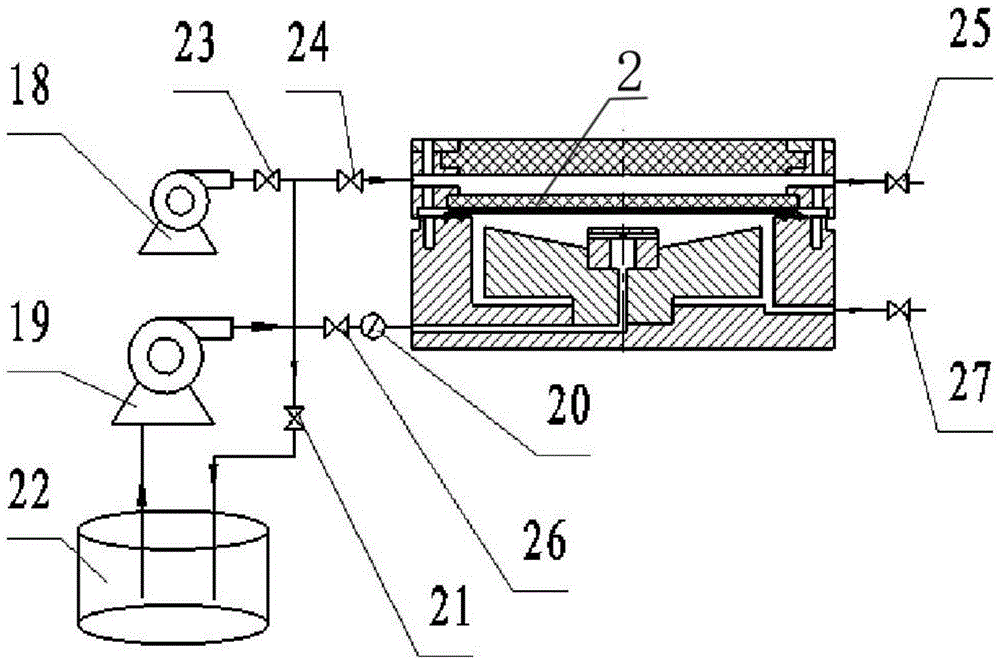

[0047] figure 1 It shows a schematic structural diagram of a device for interfacial polymerization process and membrane performance testing, including a membrane preparation and testing device and a fluid circulation system connected to the device;

[0048] The fluid circulation system includes a liquid storage tank 22 and a liquid injection pipeline; an intelligent temperature control system is provided in the liquid storage tank to ensure accurate control of the interface polymerization temperature conditions, and the liquid injection pipeline includes a liquid inlet pump 19, And the water phase solution input pipeline and the fluid input pipeline that are connected with the outlet pipeline of liquid inlet pump 19 respectively; The water phase solution input pipeline is provided with the water phase solution inlet valve 24, is provided with the fluid inlet valve on the fluid input pipeline 26 and pressure gauge 20;

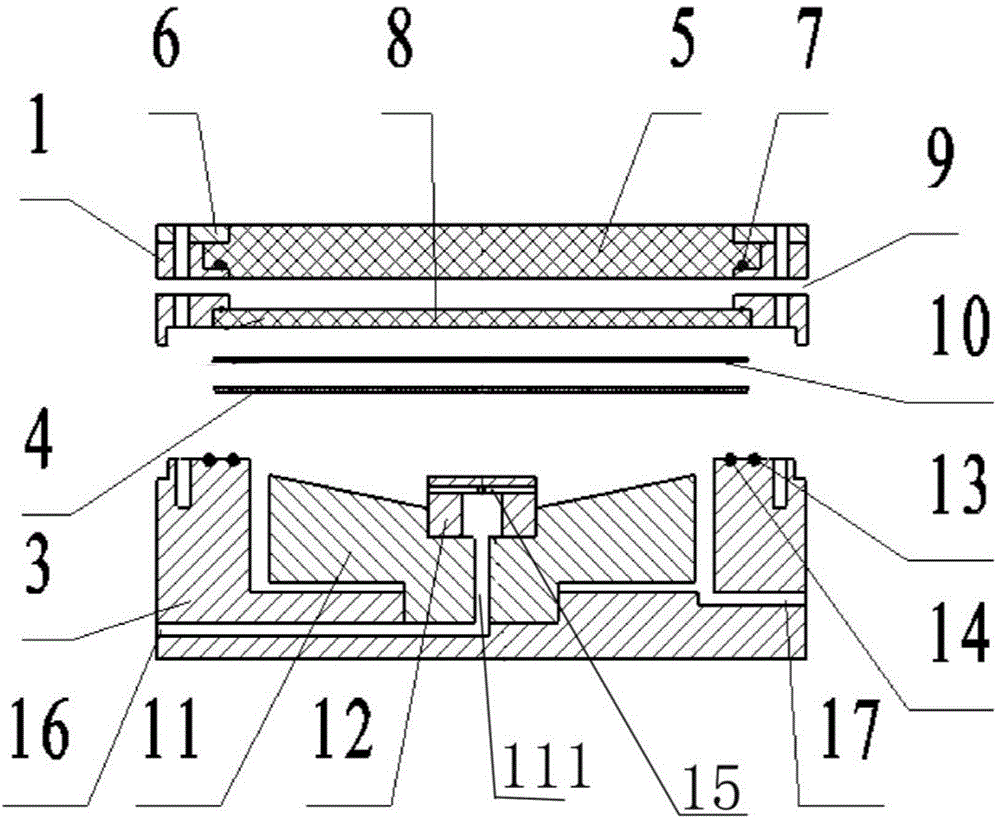

[0049] figure 2 It is shown that the membrane preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com