Liquid chromatographic sampling passage cleaning device

A liquid chromatography and cleaning device technology, which is applied in the field of liquid chromatography instrument analysis, can solve problems such as pollution, blockage, and influence on sample injection repeatability, and achieve universal applicability, improve analysis efficiency, and improve sample injection repeatability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

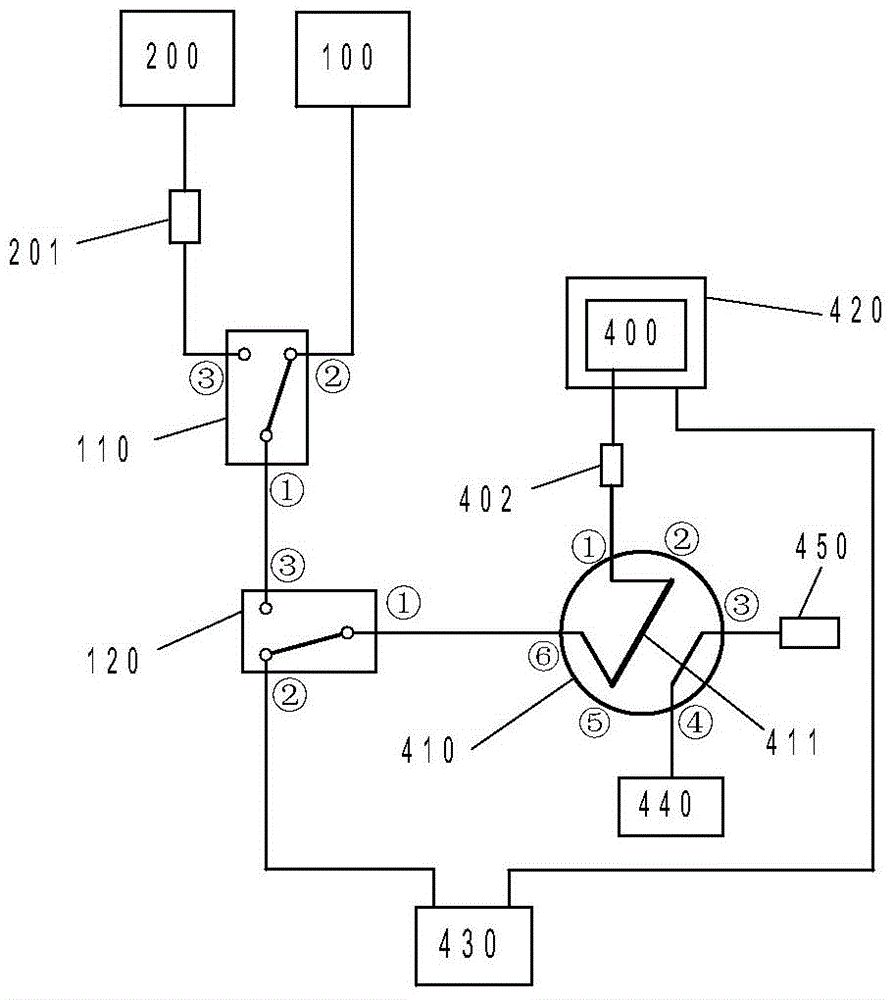

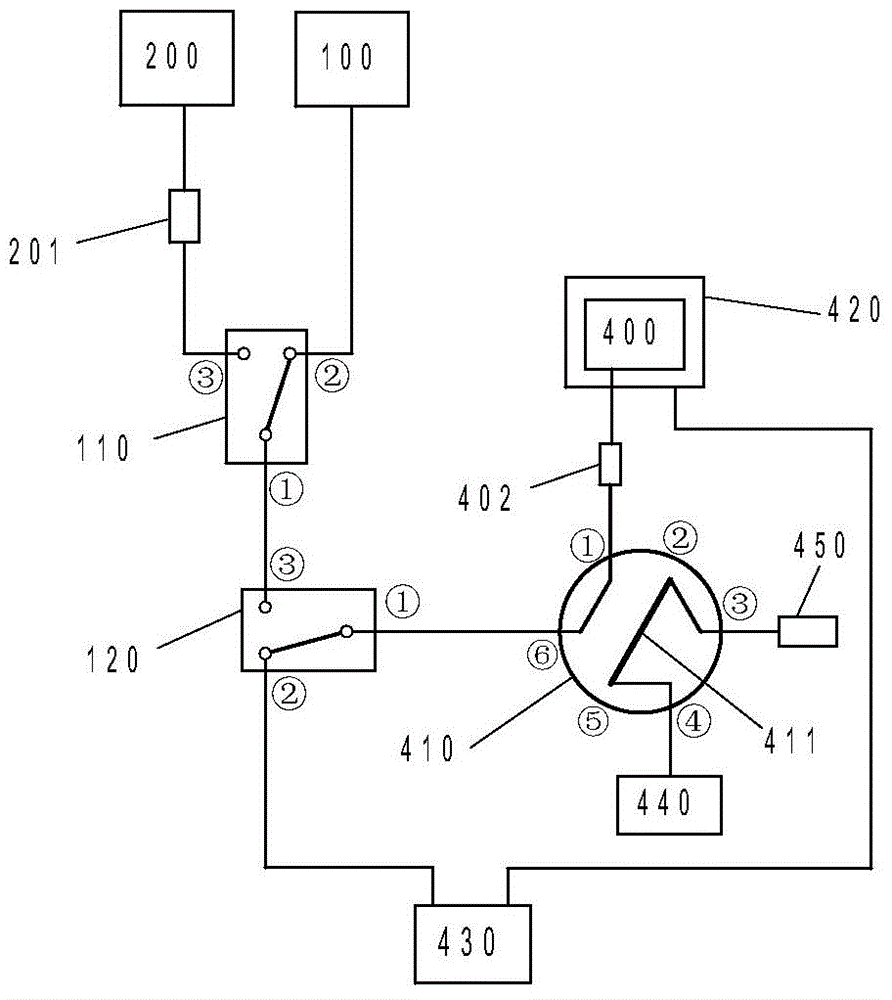

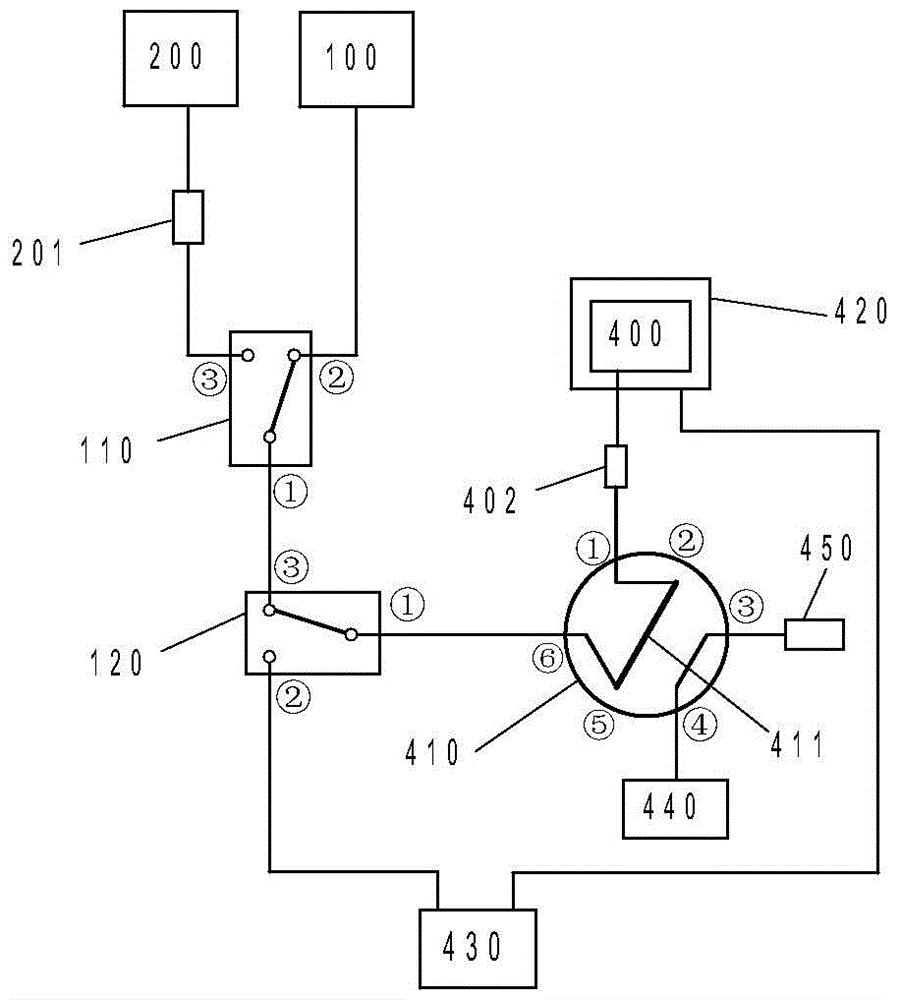

[0028] A liquid chromatography injection channel cleaning device, such as figure 1 As shown, it is mainly composed of a micro-flow infusion pump 100, a compressed air source 200, a capillary flow restrictor 201, a liquid-gas switching valve 110, a sampling-cleaning switching valve 120, a waste liquid collection cup 420, a waste liquid bottle 430, and a sampling The valve 410, the injection port 400 and the program controller are composed; the liquid-gas switching valve 110 and the injection-cleaning switching valve 120 are all three-way solenoid valves, and the injection valve 410 is a two-position six-way solenoid valve. The working status of the three valve bodies is controlled by the program controller.

[0029] The common end of the injection-cleaning switching valve 120 is connected to position ⑥ of the injection valve 410 through a pipeline, and the normally open end of the injection-cleaning switching valve 120 is connected to the waste bottle 430 by a pipeline, normally cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com