Flat spiral spring curling machine

A technology of planar scroll springs and coiling machines, applied in metal processing, metal processing equipment, safety equipment, etc., can solve problems affecting product performance, steel strip damage, and failure to form springs, etc., to eliminate additional deformation and damage, equipment The effect of high control precision and increased density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

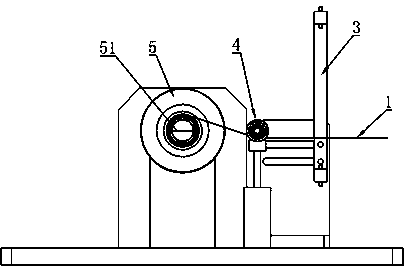

[0019] Such as figure 1 The plane scroll spring coiling machine shown is used for one-time coiling of springs, and its main structure includes a photoelectric detection device 3, a compression limit device 4, a coiling device 5, an electrical control device and a workbench.

[0020] When curling and forming, the steel strip 1 of the scroll spring passes through the detection head of the photoelectric detection device 3 at first, and the photoelectric detection device 3 can detect whether there is a steel strip at the detection head, and the detection signal is sent to the electric control device.

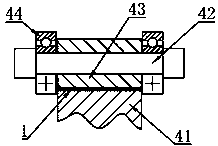

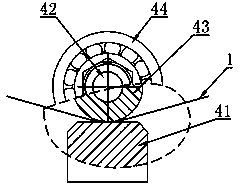

[0021] Compression limit device 4 is positioned at the rear side of photoelectric detection device 3, and the structure of preferred compression limit device 4 is as follows figure 2 , image 3 As shown, the compression limiting device includes a pressure head 41 , a ejector rod 42 , a roller sleeve 43 and a roller 44 . The lower end of the pressure head 41 is connected to the cy...

Embodiment 2

[0026] Such as Figure 4 The plane scroll spring crimping machine shown is used for the rewinding and forming of the scroll spring. Electrical controls and workbench. On the basis of the first embodiment, the material hanging device 2 and the compression protection device 6 are added.

[0027] Material hanging device 2 is located on the workbench, and a material hanging shaft for material hanging is installed on the material hanging device 2 .

[0028] The photoelectric detection device 3 is located at the rear side of the material hanging device 2, and the photoelectric detection device 3 can detect whether the steel strip 1 passes between the detection heads.

[0029] The compression limit device 4 is located on the rear side of the photoelectric detection device 3, and its structure is the same as that of the first embodiment.

[0030] The curling device 5 includes a curling shaft 51 driven by a motor.

[0031] The compression protection device 6 includes a runner, a cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com