Double-beam laser synchronous welding method for titanium alloy wallboard and rib strip through T-shaped joint

A welding method and laser welding technology, which are applied in laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems that cannot meet the high strength, super maneuverability and excellent stealth performance of the fuselage, and have not been completely and effectively solved. and other issues, to achieve the effects of stress and deformation control, high electro-optical conversion efficiency, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

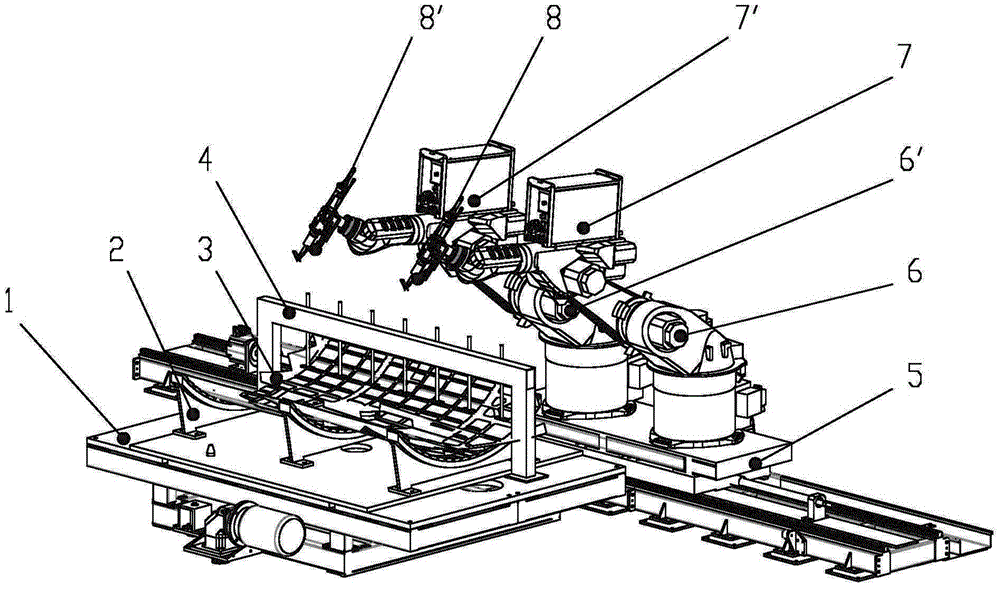

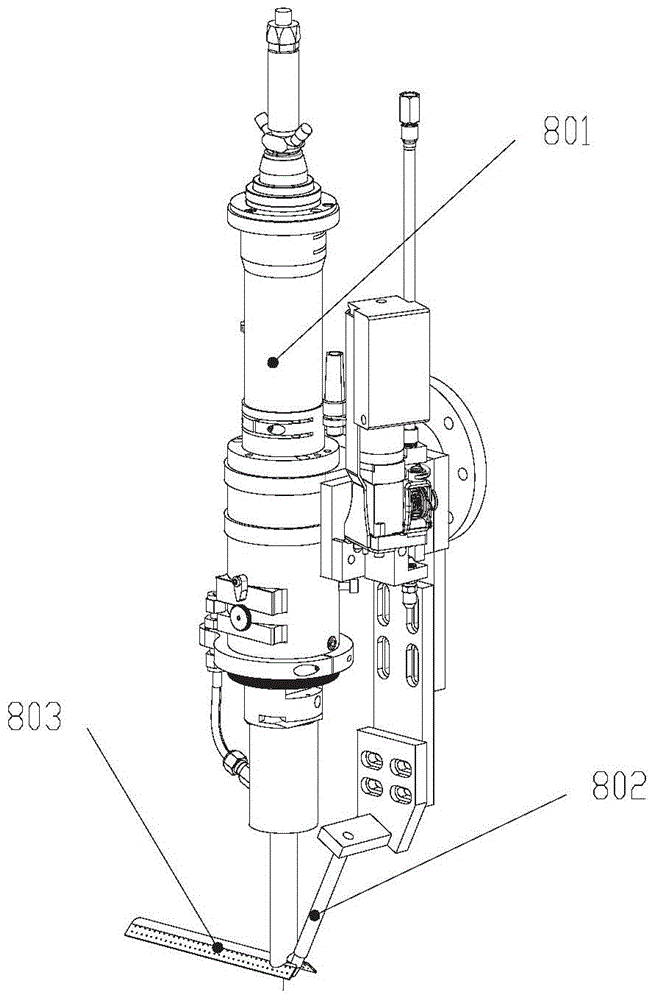

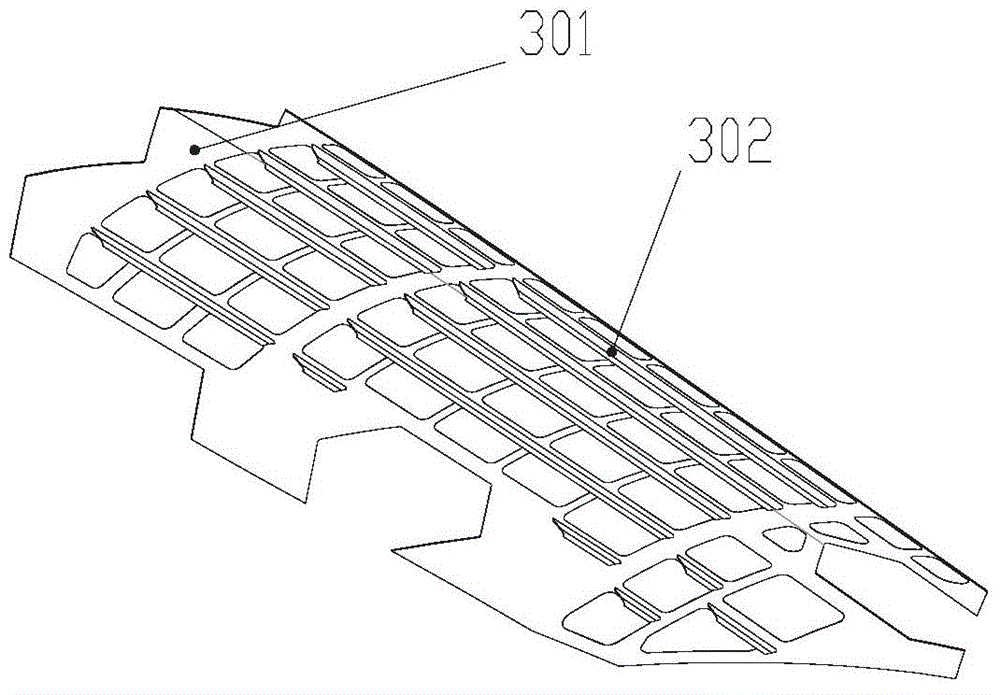

[0023] Such as figure 1 , image 3 As shown, a double-beam laser synchronous welding method for a titanium alloy wall plate and rib T-shaped joint in the present invention: the titanium alloy wall plate 301 is fixed on the mobile workbench 1 through the positioning support seat 2, and the rib 302 is vertically placed on the titanium alloy The ribs 302 are pressed on the wall plate 301 by the fixture 4 , and the ribs 302 form a T-shaped joint with the titanium alloy wall plate 301 . The first wire feeder 7 and the first laser welding device 8 are fixed on the first robot 6, the second wire feeder 7' and the second laser welding device 8' are fixed on the second robot 6', the first robot 6 and The second robot 6 ′ is attached to the outer axis 5 of the robot. Both sides of the T-shaped joint are welded synchronously by the first laser welding device 8 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com