Double main shaft turning-milling combined machining method for aeroengine case

An aero-engine and composite machining technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of low processing efficiency, complex processing technology, large processing deformation, etc., to achieve concentrated processing procedures, improve processing accuracy, and reduce processing. deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] 1784M71P01 engine combustion chamber casing, nickel-based high-temperature alloy INC0718 material, maximum diameter 803.99mm, height 293.88mm, blank weight 190 kg, forging parts, rough turning processing on FVL-1250VT vertical lathe, and then provided by the present invention The dual-spindle turning-milling compound processing method is used for processing, and the operation steps are:

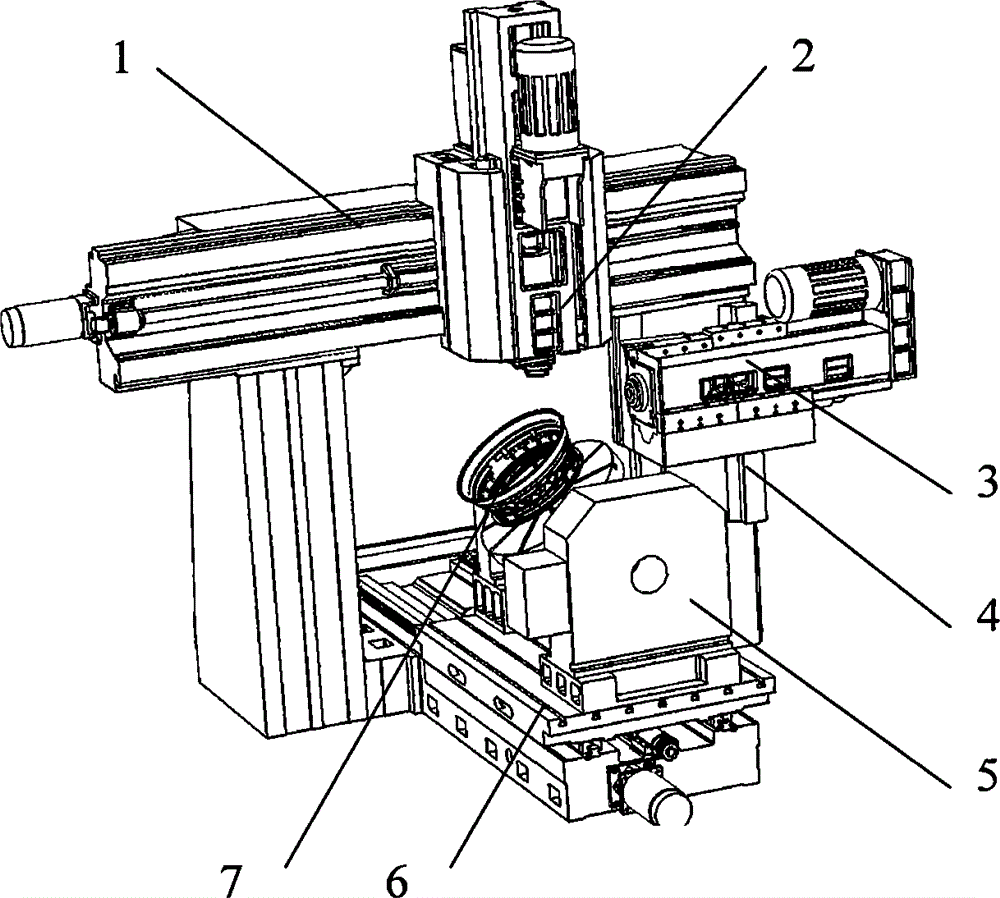

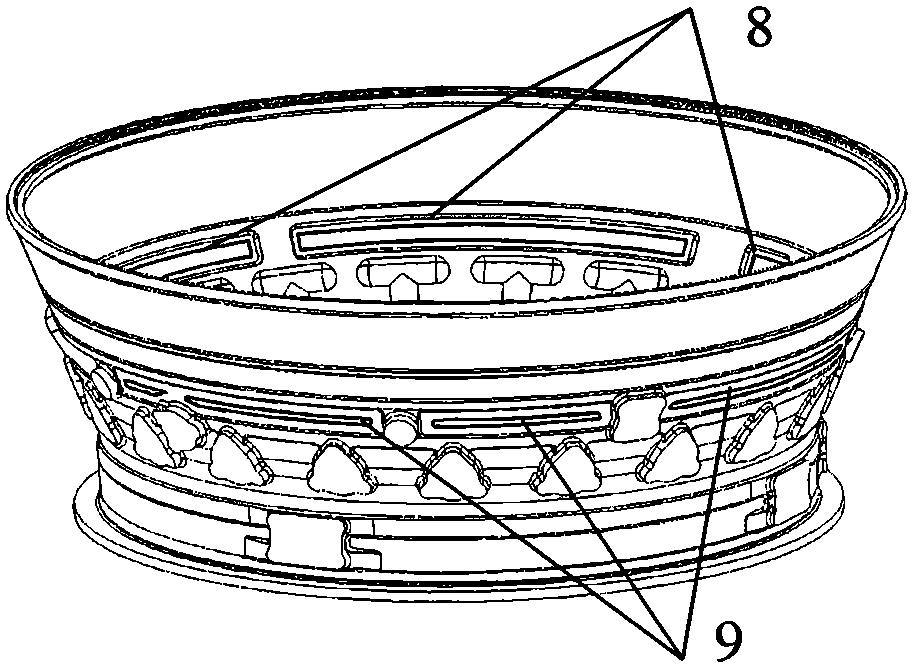

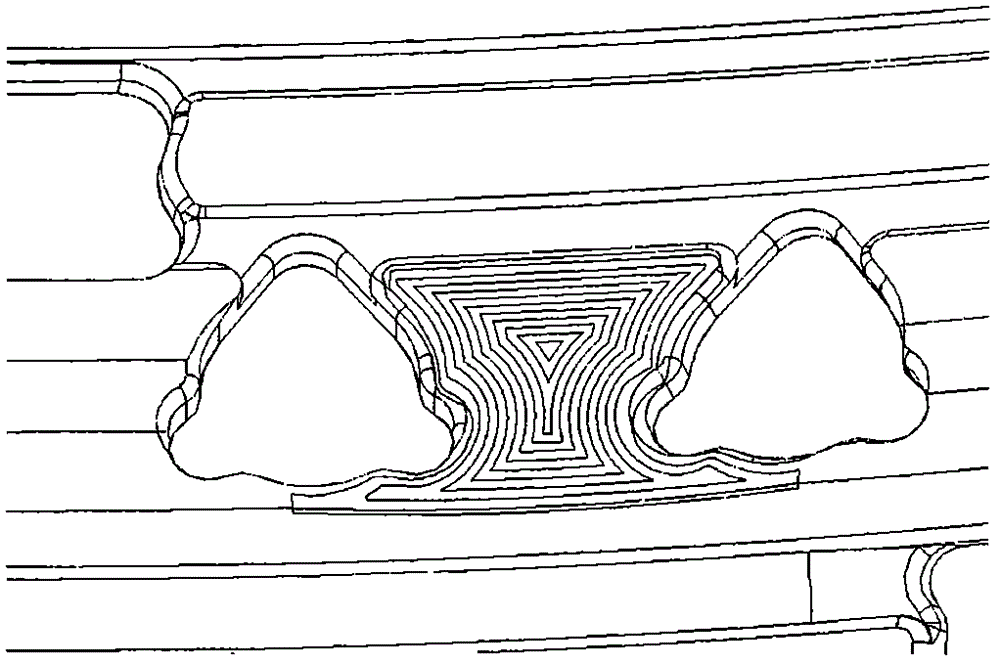

[0024] Step 1: Analysis of the dual-spindle turning-milling composite machining process of casing parts: there are annular ribs for strengthening, bosses for installing pipelines, and cavity grooves for reducing weight distributed on the surface of the casing, and the cavity grooves are in the machine. The distribution on the inner and outer profiles of the casing is consistent, and the processing area can be divided into 16 different processing areas including the inner and outer wall ring surfaces, cavity grooves and bosses. The upward one-time clamping method determines the dual-spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com