A kind of preparation method of moxa making car roof trim

A moxa and interior technology, applied in the field of automotive roof interior materials, can solve the problems of automotive interior pollution, driver and passenger injury, etc., to reduce pollution, increase contact area, and prevent influenza virus Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

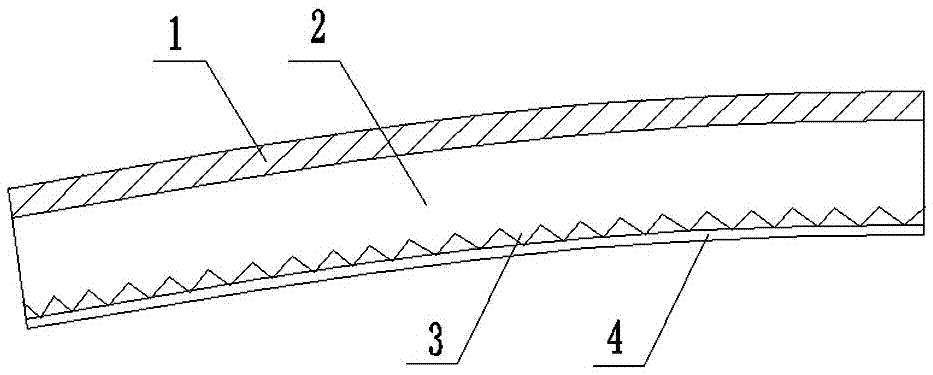

[0017] Such as figure 1 The shown car roof trim made of moxa has a moxa roof 2 that is formed by hot pressing of moxa, mugwort activated carbon and elm powder and is adapted to the shape of the car roof. The inner surface of the moxa roof has The protrusion 3 of corrugated type is attached with the cloth 4 made of moxa velvet and Gastrodia elata or silk blending, and the back side of the moxa velvet roof is sprayed with a layer of waterproof, moisture-proof and heat-insulating aluminum film 1.

[0018] The preparation method of the car roof trim is prepared according to the following steps:

[0019] 1. Select high-quality mugwort leaves to extract moxa, and comb it with the wind to form raw moxa;

[0020] 2. Add elm wood powder and activated carbon formed by carbonization of mugwort leaves to the raw material moxa. The weight ratio added is moxa: elm powder: activated carbon = 50:1:1. Moxa roof, the thickness of the moxa roof is 2-10mm, and the inner surface of the moxa roof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com