A kind of treatment method of recycled polyester production wastewater

A technology for the production of wastewater and recycled polyester, which is applied in natural water treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of high energy consumption and high processing cost of distillation, and achieve energy consumption Low cost, low waste water treatment cost, and the effect of improving COD removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

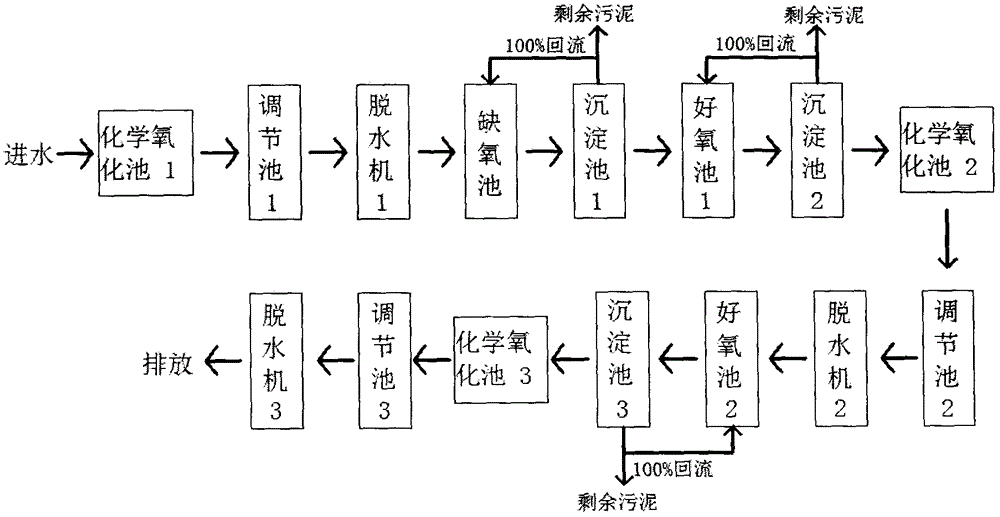

[0029] Depend on figure 1 It can be seen that the present invention is a method for treating wastewater from recycled polyester production, which includes physical chemical treatment and biological treatment, and includes the following steps in turn:

[0030] (1) The wastewater is firstly oxidized in chemical oxidation tank 1 (first chemical oxidation tank), and part of COD is removed by the action of chemical reagents, and part of the refractory organic matter is decomposed into easily degradable organic matter with smaller molecular weight to improve its biodegradability.

[0031] (2) The wastewater after chemical oxidation enters the neutralization adjustment tank 1, and the pH of the wastewater is adjusted to 6.5.

[0032] (3) The wastewater whose pH value is adjusted to 6.5 is dehydrated by centrifugal dehydrator 1 .

[0033] (4) The dehydrated wastewater is subjected to the first biochemical treatment through anoxic tank - sedimentation tank 1 (first sedimentation tank)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com