Multifunctional soap-making system

A soap-making system and multi-functional technology, applied in the direction of forming soap, cutting soap, etc., can solve the problem of single soap-making equipment products, achieve the effect of reducing fragrance volatilization and dust pollution, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

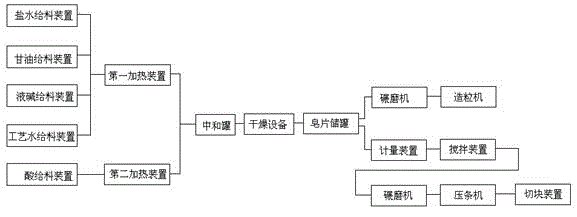

[0016] This embodiment discloses a multifunctional soap making system capable of producing sheet soap and soap grains at the same time, such as figure 1 As shown, it includes a sequentially connected quantitative feeding device, heating device, neutralization tank, vacuum drying equipment and soap flake storage tank, and the multifunctional soap making system also includes a soap particle device and a soap making device; the heating device Including a first heating device and a second heating device, the quantitative feeding device includes a brine feeding device, a glycerin feeding device, a liquid caustica feeding device, a process water feeding device and an acid feeding device, and the brine feeding device device, glycerin feeding device, liquid caustic soda feeding device, and process water feeding device are connected in series with the first heating device, and the acid feeding device is connected in series with the second heating device, and the first heating device and...

Embodiment 2

[0020] This embodiment also discloses a multifunctional soap making system capable of simultaneously producing lamellar soap bodies and soap granules. Its structure is basically the same as that of Embodiment 1. Volatile and dust pollution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com