Construction method of bituminous coating pile in sandy foundation

A technology of bituminous coating and construction method, which is applied in basic structure engineering, sheet pile wall, building and other directions, can solve the problems of reducing negative frictional resistance, unable to effectively solve negative frictional resistance, affecting the construction quality of pile foundation engineering, etc. Achieve the effect of reducing negative friction resistance, improving construction quality and reliable engineering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

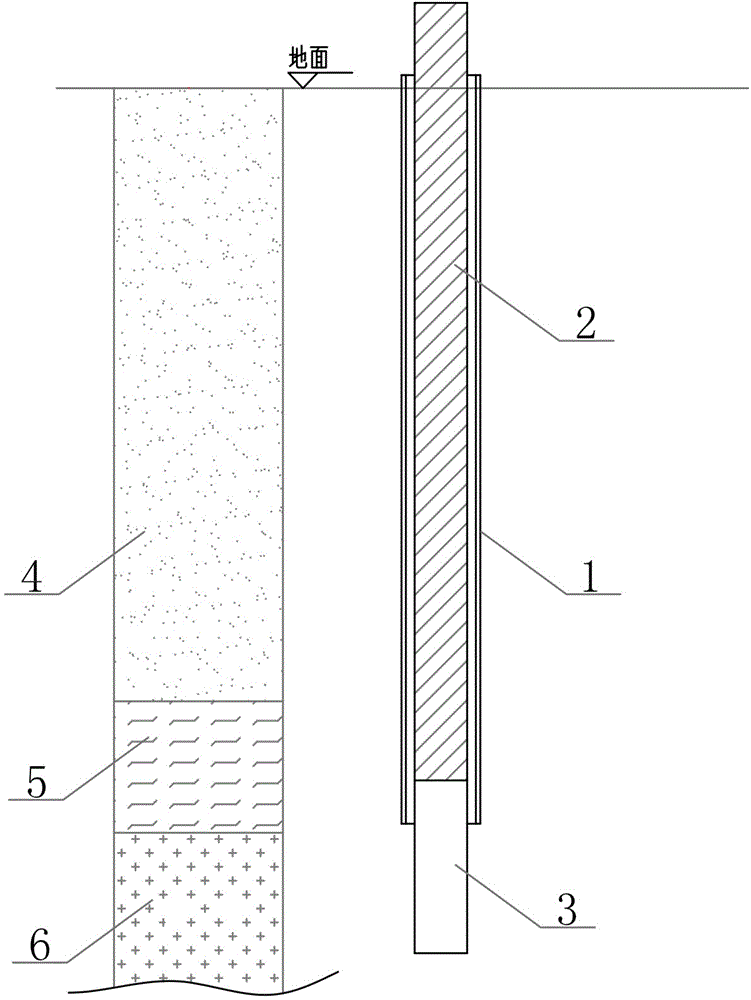

[0015] See attached figure 1 , the present invention will be further explained by taking a certain newly-built craneway project as an example. The geological conditions of this project are the backfill medium-coarse sandy soil layer 4 with a thickness of about 25m in the upper part, and the soft soil layer 5 with a thickness of about 6m lying below. The pile foundation of the craneway adopts Φ600 asphalt-coated PHC pipe pile 2, the specific construction steps are as follows:

[0016] (1) Drive into the steel casing

[0017] After the pile hole is positioned, a steel casing 1 with a diameter of Φ700 and a wall thickness of 10mm is selected, and the submerged steel casing 1 is penetrated into the backfill medium-coarse sandy soil layer 4 with a thickness of about 25m by using a vibratory hammer to drive into the backfill medium-coarse sand In the soft soil layer 5 lying under the soil layer 4, remove the sand and soil in the steel sleeve pipe 1 then.

[0018] (2) Driving into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com