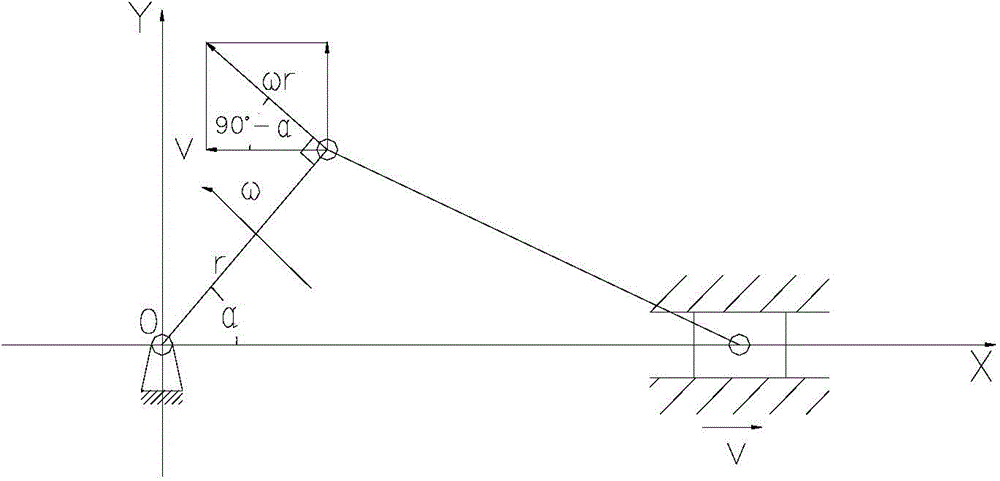

Mechanical-energy-storing type incomplete gear quick-return reciprocating mechanism and working method thereof

A complete gear and reciprocating mechanism technology, applied in the direction of mechanical equipment, belts/chains/gears, components with teeth, etc., can solve the problems of transmission mechanism damage, energy waste, and insufficient return speed, etc., to reduce load and damage , strong operability, improved durability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

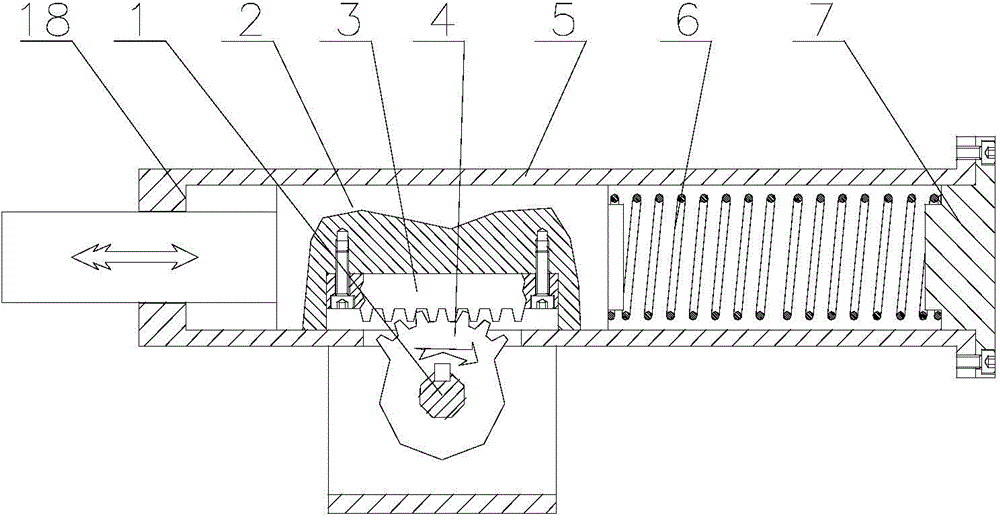

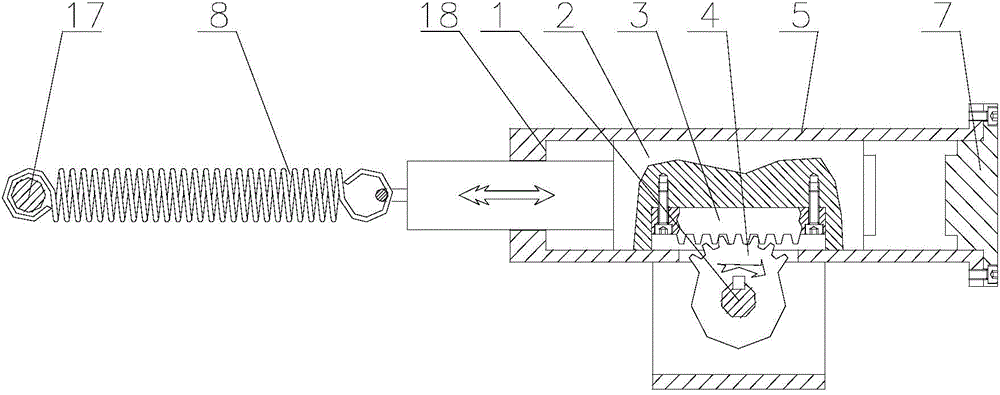

[0046] Embodiment: a mechanical energy storage type incomplete gear quick return reciprocating mechanism, characterized in that it includes a reciprocating body, an incomplete gear 4, an energy storage element, and a power mechanism; the reciprocating body is connected with the energy storage element, and is The toothed part of the reciprocating body meshes with the toothed part of the incomplete gear 4; the incomplete gear 4 is connected with the power mechanism. (See Figure 2-Figure 7 )

[0047] The reciprocating body is a linear reciprocating body 2 or a circular reciprocating body 14; the linear reciprocating body 2 is connected to the rack 3, and the rack 3 meshes with the toothed part of the incomplete gear 4; The complete gear is coaxially fixedly connected and installed, and the toothed part of the passive incomplete gear meshes with the toothed part of the incomplete gear 4 . (See Figure 2-Figure 7 )

[0048] The energy storage element is an energy storage eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com