Gland packing

A gland and yarn technology, applied in the field of gland packing, can solve problems such as leakage, adverse effects of flatness, and adverse effects of sealing performance, and achieve the effects of improving sealing performance, improving sealing performance, and increasing the cross angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

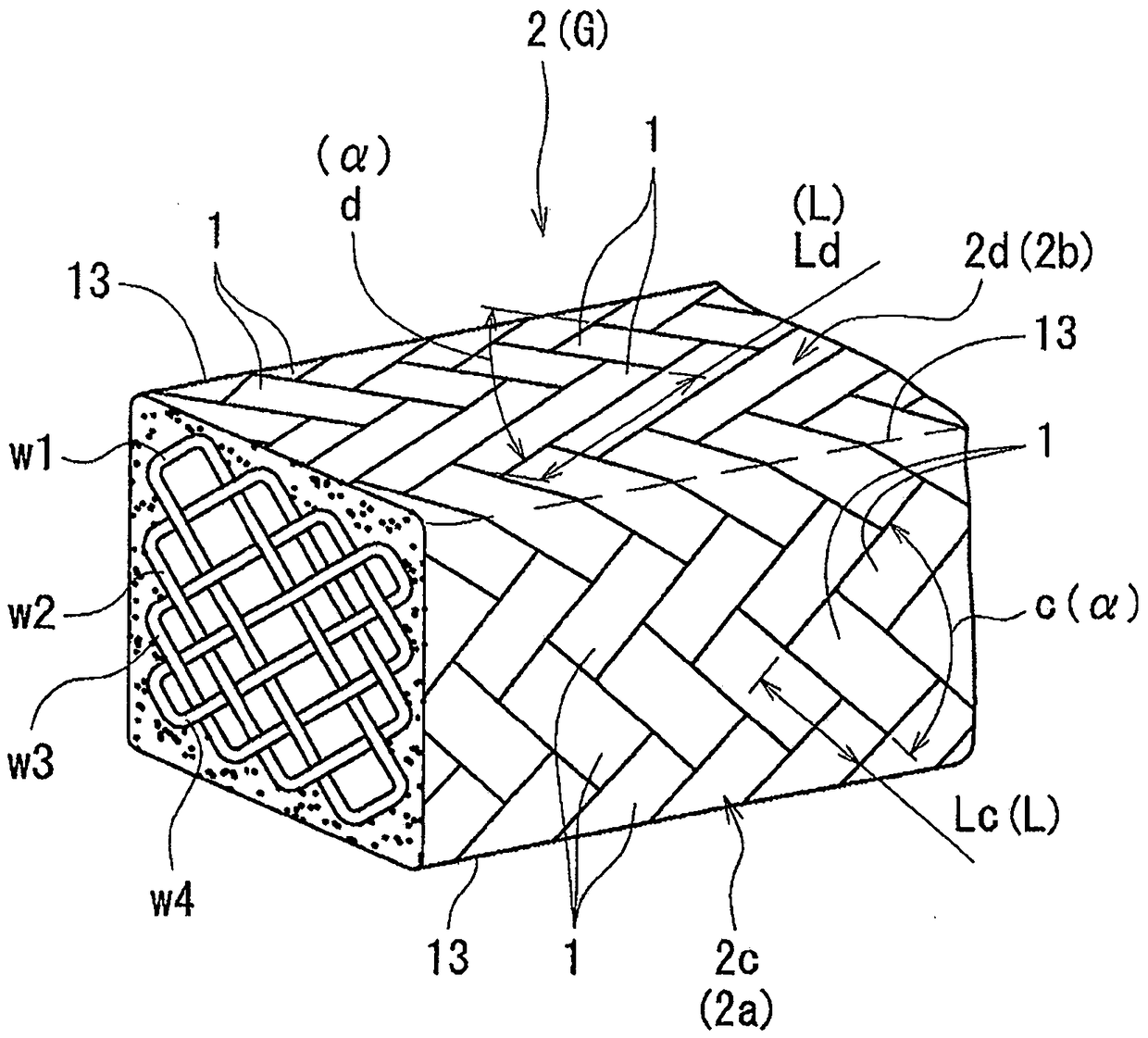

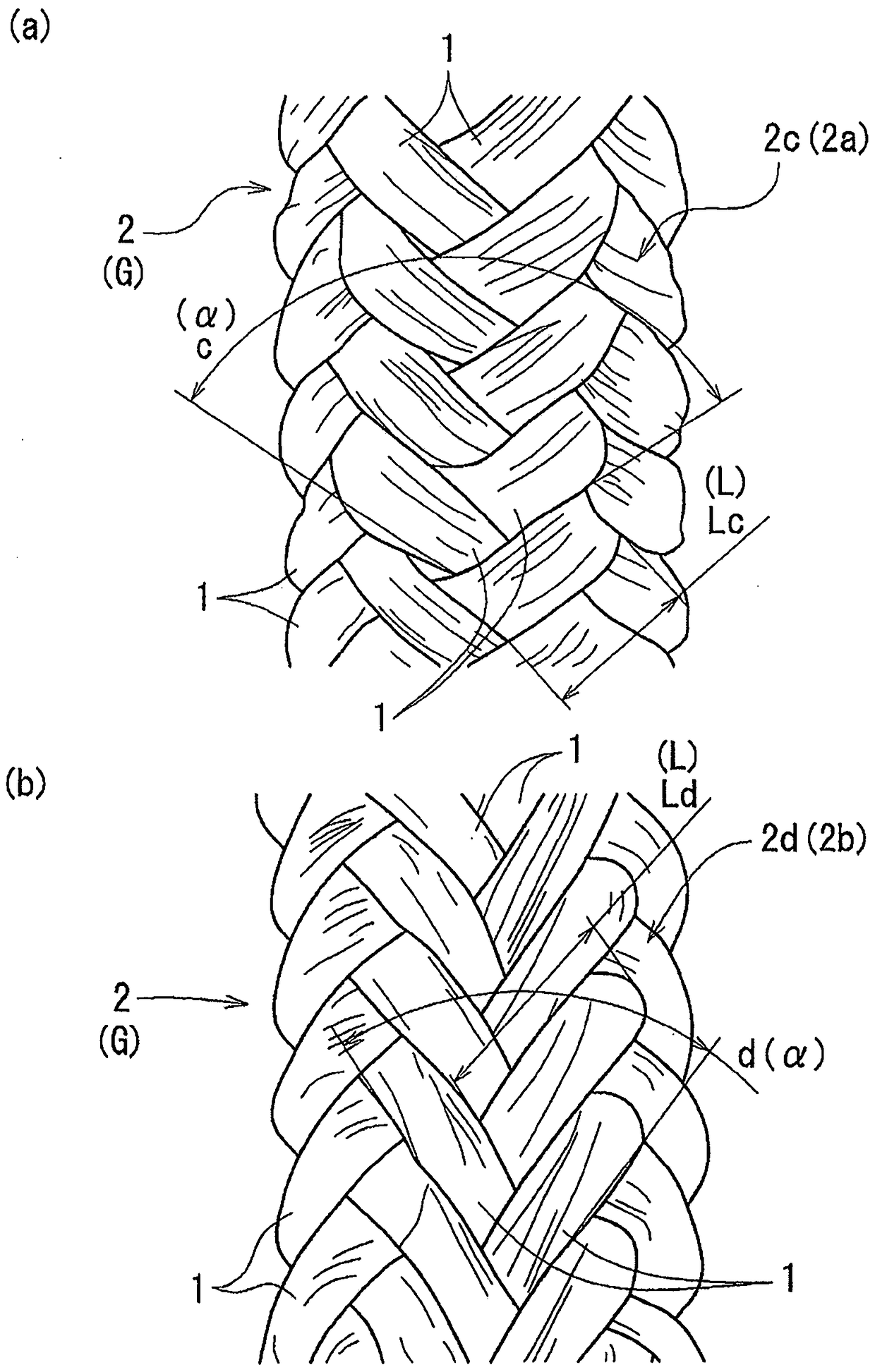

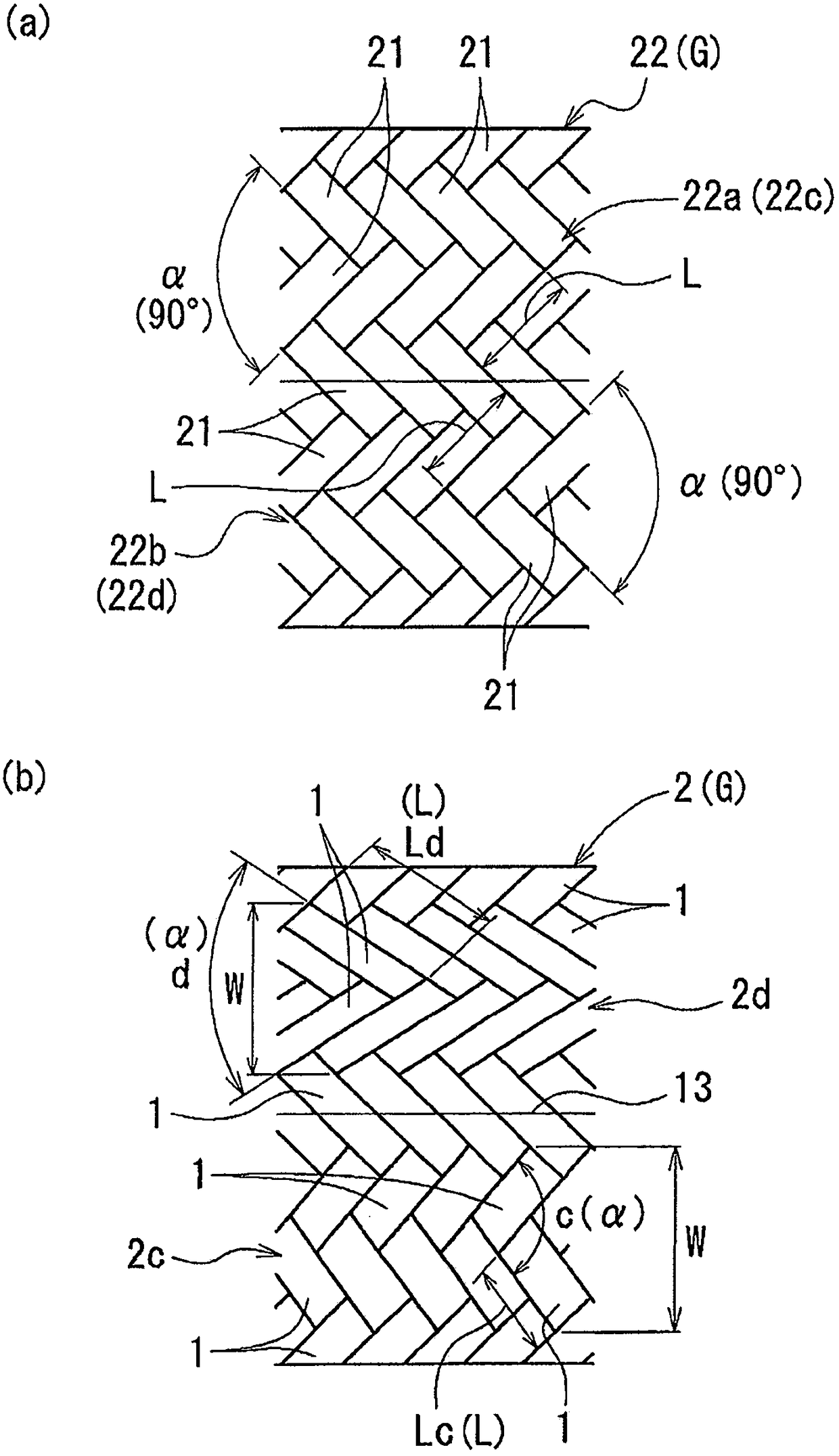

[0057] The gland packing G of the present invention is as Figure 1 ~ Figure 3 As shown, it is composed of a strip-shaped body 2 formed by weaving a plurality of yarns 1, and is set to have a square cross-section. The direction of the yarn 1 on the cross-section is parallel to the diagonal, and the number of moving paths of the yarn 1 is 4. Furthermore, the intersecting angle α of the yarn 1 exposed on the side surfaces 2a, 2b, 2c, and 2d of the strip-shaped body 2 is woven such that the adjacent side surfaces among the four side surfaces 2a to 2d are different in angle a≠b.

[0058] The structure and cross section of this gland packing G (ribbon 2) are as follows: figure 1 shown. That is, four yarn (knitting yarn) paths w1 to w4 extending in parallel along the diagonals of a square and set to intersect each other (see Figure 5 , 6 ), a plurality of yarns 1 on each path are knitted while moving sequentially in such a manner as to alternately overlap and intersect each ya...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com