A connection seat for heliostats in a tower-type solar thermal power station

A tower-type solar energy and connection seat technology, which is applied in the direction of solar thermal power generation, solar thermal devices, heating devices, etc., can solve the problems of high probability of damage to the connection seat and high replacement cost, and achieve cost savings, low maintenance costs, and reduced post-maintenance cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

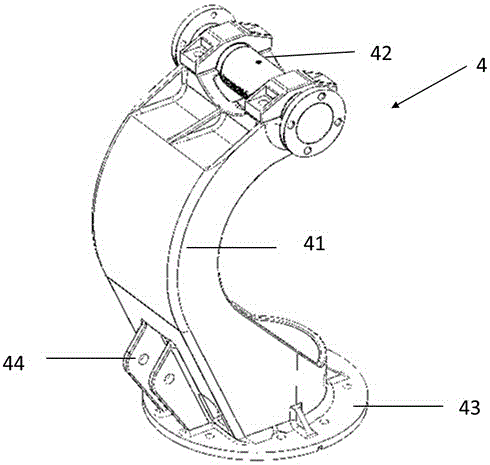

[0050] Such as image 3As shown, the connecting seat 4 provided by the present invention includes a connecting seat body 41 , a bearing component 42 , a connecting seat flange 43 and a header pin mounting hole 44 . Wherein, the connection seat body 41 is an arc-shaped support member. In other preferred embodiments, the connection seat body 41 can be a support member with one side sunken inward, and the shape of the depression can be semicircular, “concave” or Any other structural shape can accommodate the support of the main beam 121 of the mirror bracket 12; the head pin mounting hole 44 is located on the arc back of the connecting seat body 41, and the head pin mounting hole 44 is used for the horizontal angle driving device with the mirror body 1 2 are connected, and the elevation angle rotation of the mirror body 1 can be controlled by the horizontal angle driving device 2; the connecting seat flange 43 is located at the bottom of the connecting seat body 41, and the conne...

Embodiment 2

[0060] In this embodiment, except the following part of the structure is different from the first embodiment, other parts of the structure and parameters are the same as the first embodiment. The differences are as follows:

[0061] Such as Figure 10 , Figure 11 As shown, the bearing component 42 in this embodiment includes a bearing 421 , a horizontal shaft 422 , and a sleeve 424 . The sleeve 424 is sheathed on the outside of the bearing component 42 and inside the hoop. Two ends of the sleeve 424 are provided with sealing rings 423 . In addition, the sleeve 424 is also provided with a vent plug 48 , and the vent plug 48 is also used to inject lubricating oil into the bearing 421 , and at the same time discharge the gas in the sleeve 424 to facilitate the assembly of the entire bearing component 42 .

[0062] The setting of the sleeve 424 can further protect the bearing 421, and the setting of the sealing ring 423 forms a sealed environment in the sleeve 424, which can m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com