Heat pump dryer

A dryer and heat pump technology, applied in dryers, drying, local stirring dryers, etc., can solve the problems of backward drying equipment technology, long construction period, inconvenient debugging, etc., to save material costs and construction costs , Good energy-saving effect, convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

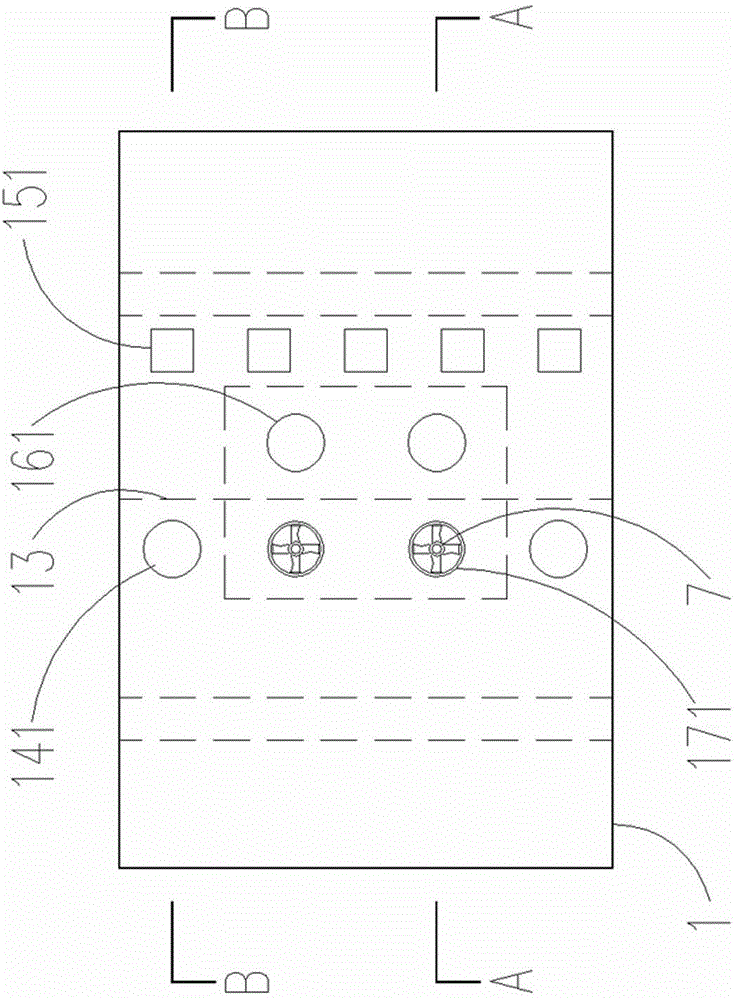

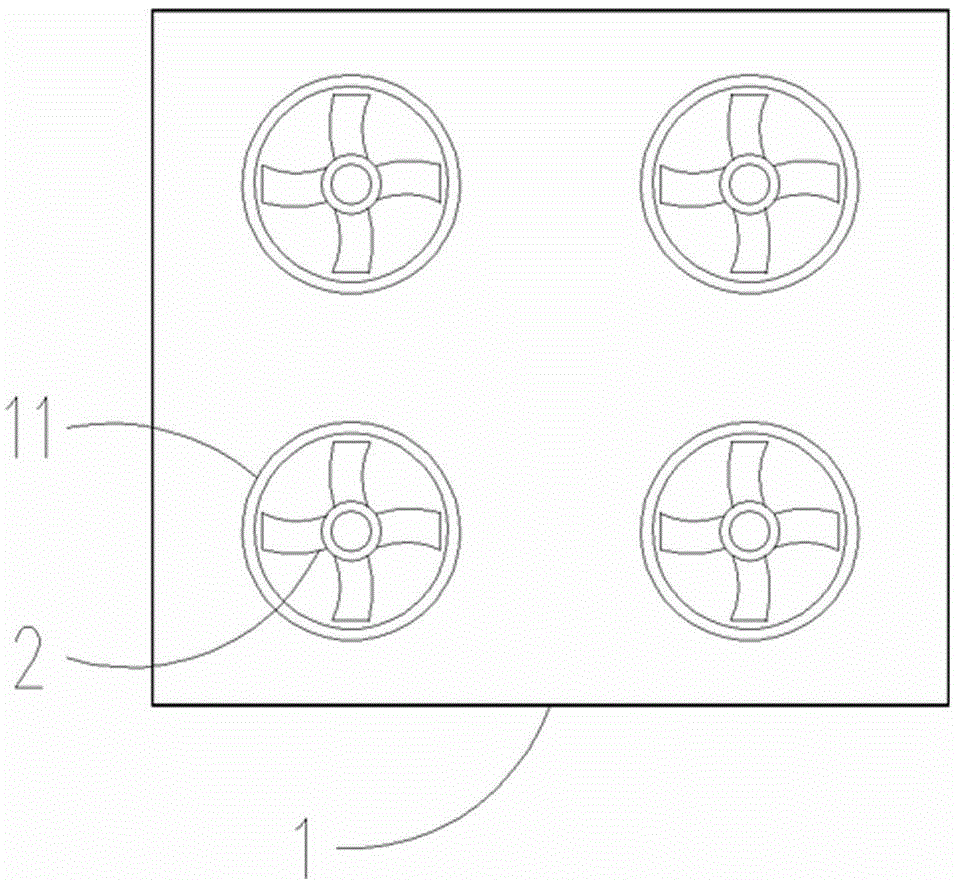

[0031] As attached Figure 7 As shown, the indoor air heating method of the heat pump dryer of the present invention: Turn on the fan 2 at the indoor circulation fan port 11 and the outdoor circulation fan port 12, and the outdoor hot air enters the outdoor air collector 15 through the air hole 151 and passes through the evaporator 5. Blow out from the outdoor circulation fan port 12; indoor air enters the indoor air heating chamber 14 through the indoor air circulation port 141, passes through the condenser 4, and blows into the room from the indoor circulation fan port 11. Turn on the air compression pump 6, the heat exchange medium in the air heat source heating system absorbs heat and vaporizes in the evaporator 5, compresses it into high temperature gas by the compression pump, and then circulates to the condenser 4 to release heat into low temperature gas, and finally Circulate to the evaporator to absorb heat; when the indoor air passes through the condenser 4 in the indo...

Embodiment 2

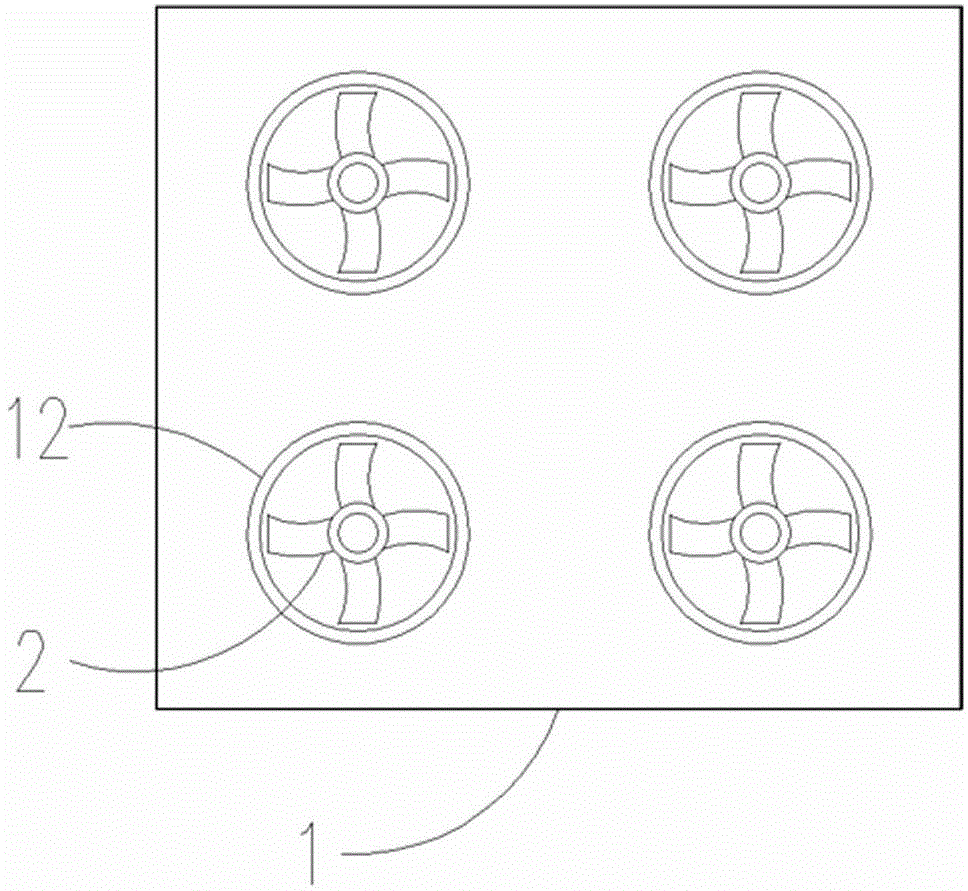

[0033] As attached Figure 8 As shown, the exhaust dehumidification process of the heat pump dryer of the present invention: when the indoor air humidity exceeds a specified value, the ventilation fan 7 installed on the exhaust port 171 of the exhaust cavity 17 is started to pass the indoor hot and humid air The exhaust cavity 17 passes through the hot air cavity of the air heat exchanger 3 and is discharged into the outdoor air heat collecting chamber 15, and finally blown out from the outdoor circulation fan port 12 of the outdoor air heat collecting chamber 15; at the same time, the effect of the negative pressure inside and outside The outdoor dry air is sucked in from the air inlet 161 of the air inlet cavity 16, passes through the cold air cavity of the air heat exchanger 3, enters the indoor air heating chamber 14, and enters the drying room after being heated by the condenser 4; 3Using the temperature of the exhausted hot and humid gas to preheat the added dry air to ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com