Expert control method for burning double-chamber lime furnace

A technology of expert control and double-chamber kiln, applied in the direction of program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of system nonlinearity, time lag and inaccurate temperature measurement in the kiln, so as to reduce labor intensity, The effect of stable operation and improved operation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

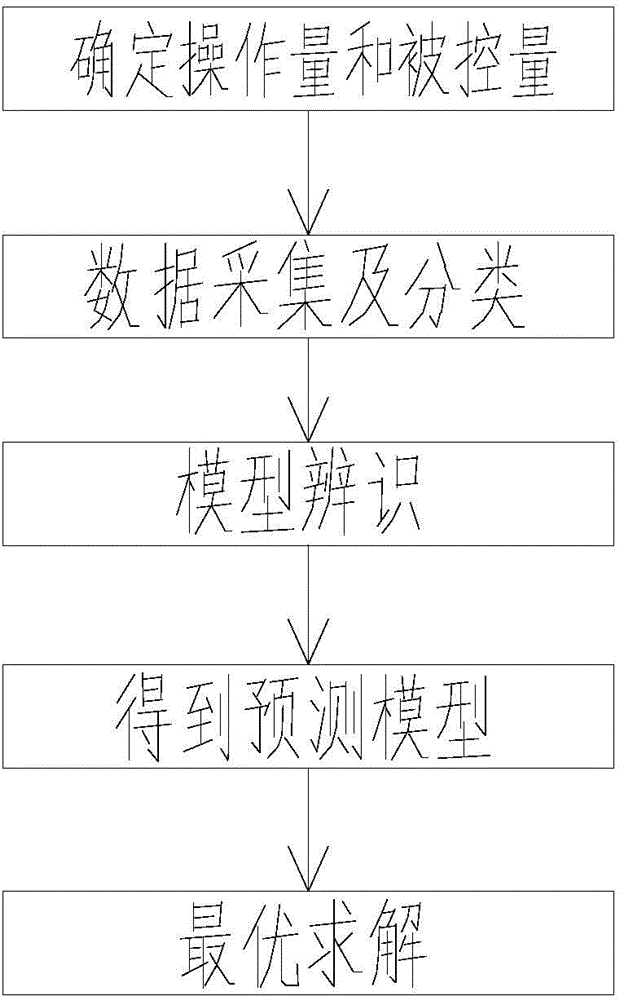

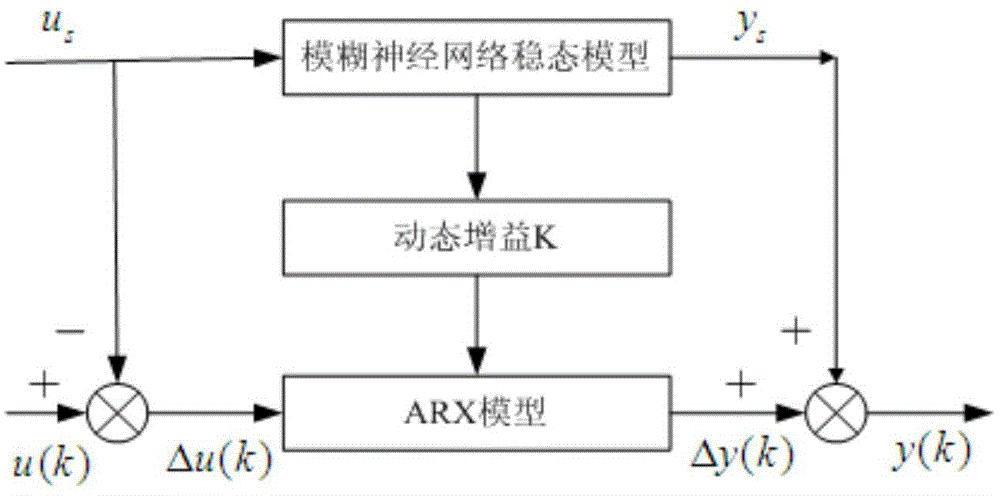

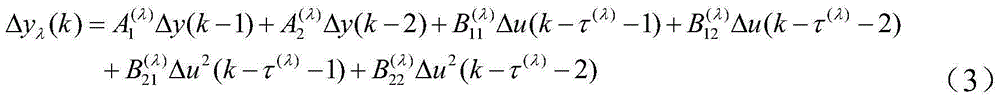

[0018] An expert control method for lime double-chamber kiln calcination, comprising the following steps:

[0019] a. Determine the operating volume and controlled volume: The calcination process of the lime double-chamber kiln can be divided into two lines: the material path and the gas path. The direction of the material path is: the lime raw material enters the kiln preheating section under the action of the feeding system Then it enters the calcination section under the action of gravity for calcination, and finally the finished product is produced after passing through the cooling section; the direction of the gas path is exactly opposite to the direction of the material path under the action of the exhaust fan of the kiln tail; The quality of calcination directly affects the quality and productivity of lime, and the quality of calcination mainly depends on the accurate control of the temperature in the double-chamber kiln and the combustion status of the coal in the kiln....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com