Splashing pre-warning device for converter steelmaking

A converter steelmaking and video conversion technology, which is applied in the manufacture of converters, etc., can solve problems such as reducing the amount of steel tapping, causing fires, converter splashing, etc., and achieves the effects of ensuring safe and reliable operation, improving product quality, and improving operation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

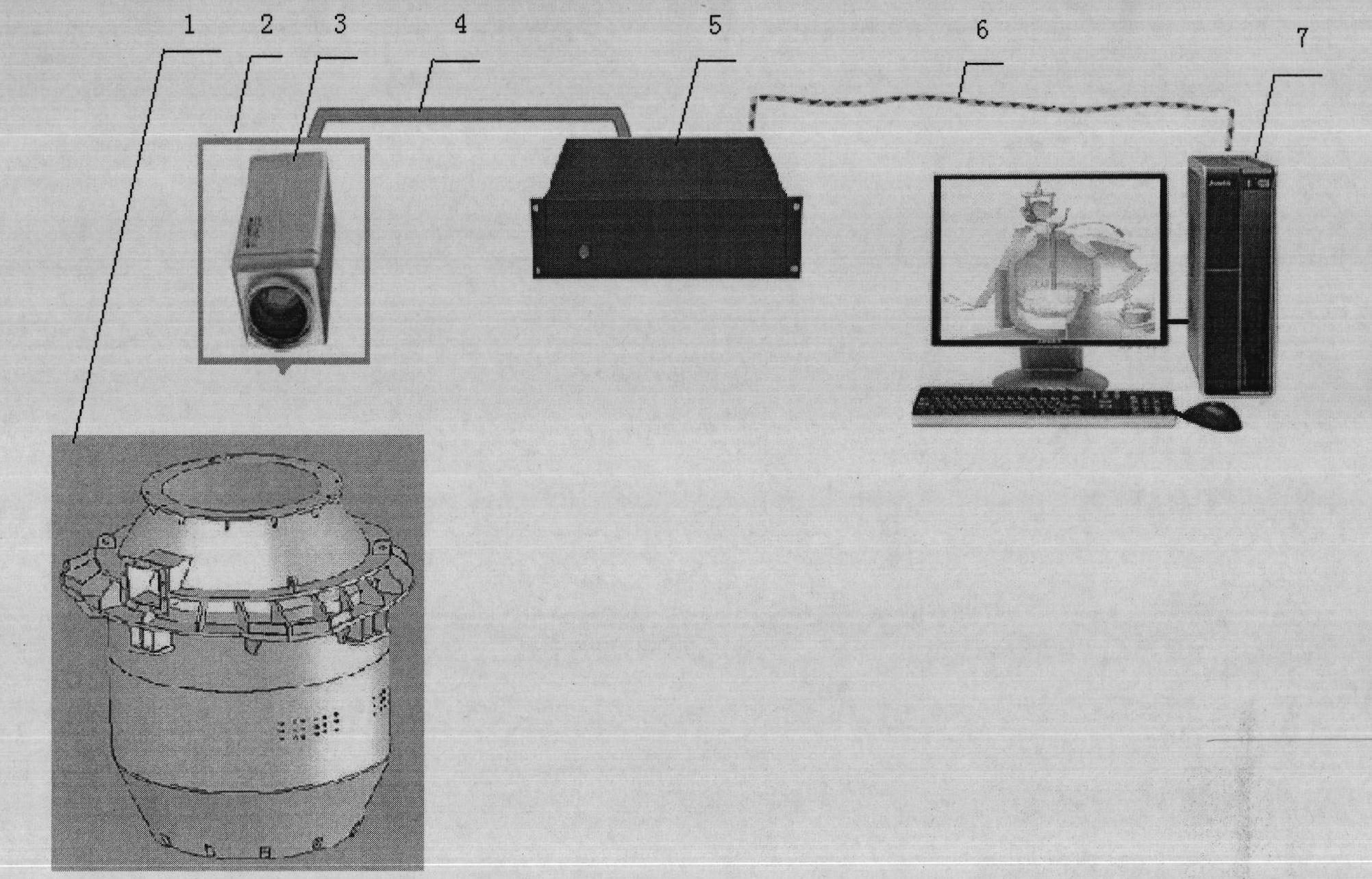

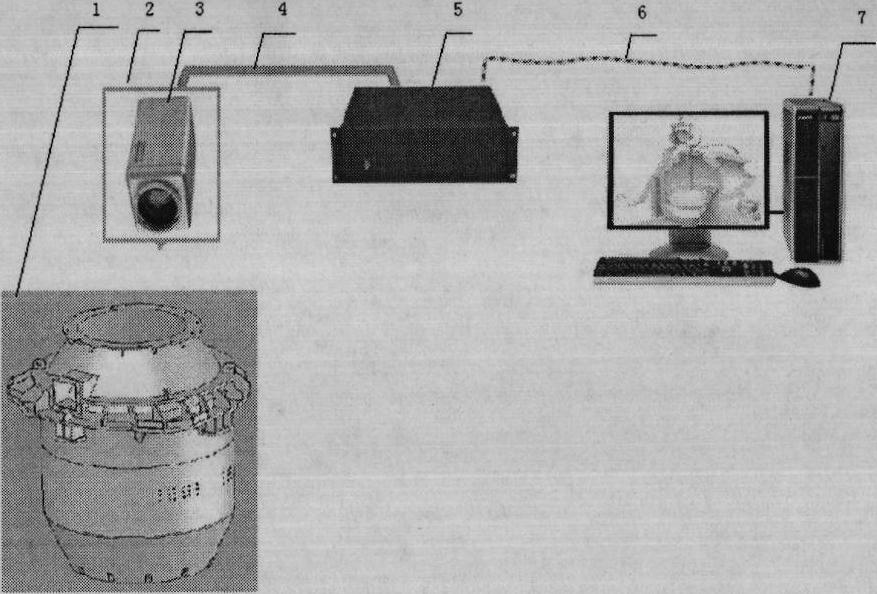

[0016] 1. Integrate the air curtain protection unit with the image acquisition unit, connect the instrument air source, maintain a slight positive pressure, and install it above the oxygen gun port of the converter. The end of the device is connected by a flange, and there are air source and video signal interfaces on it. , using the quick plug method, and the other end, using the fixed terminal method on the video conversion unit, to connect all the signal lines numbered according to the construction drawings to the specified terminals.

[0017] 2. The video conversion unit transmits the video signal to the monitoring computer screen through the network communication cable.

[0018] 3. Configure the monitoring computer, install the network card specially used for image communication on the computer with Windows XP operating system, and install the corresponding driver, then install the WINCC screen programming software, and install the pre-edited monitoring program Copy it to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com