A Vacuum Optical Experimental System with a Fine-tuning Mechanism Outside the Cabin

A technology of optical experiment system and fine-tuning mechanism, applied in the field of optical experiment and optical detection, can solve the problems of saturation, limitation, large vibration, etc., to achieve the effect of large choice, avoidance of outgassing, and improvement of pumping speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

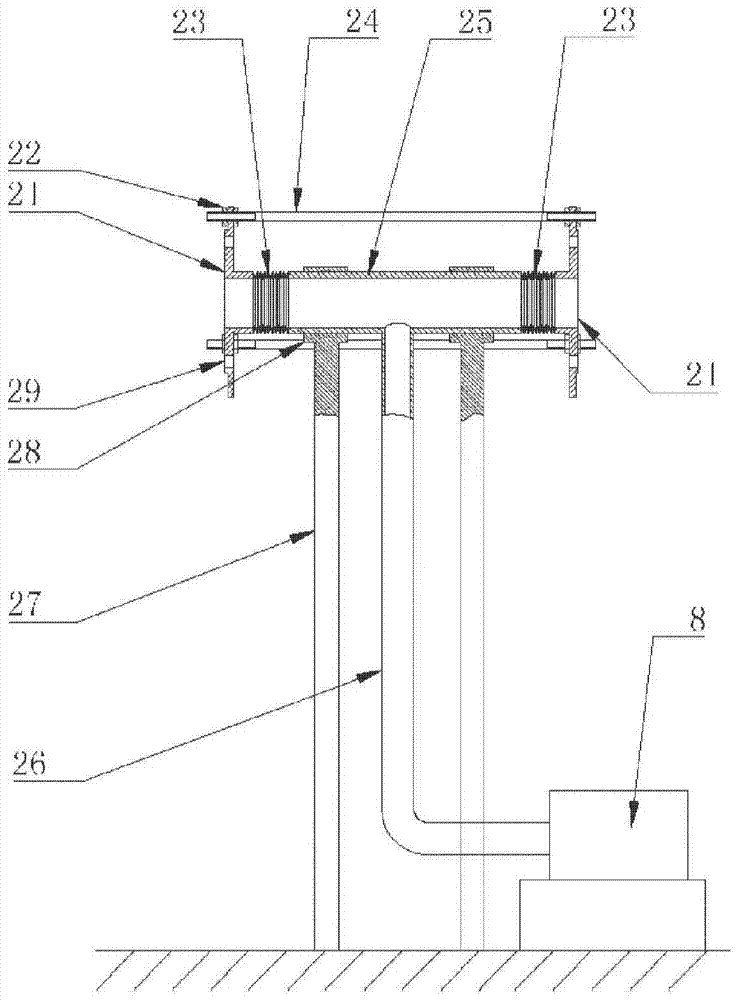

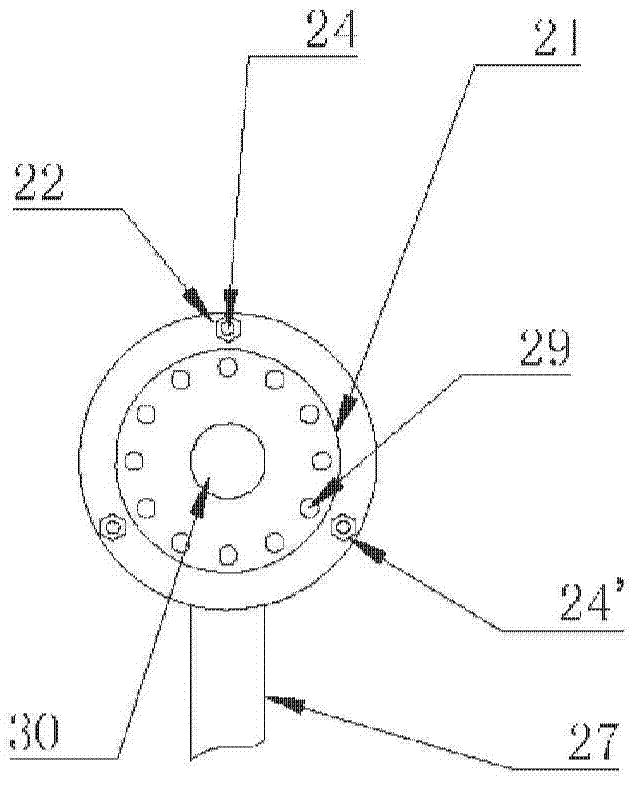

[0032] In the present invention, the optical components of the experimental system are fixed on the adjustment table outside the cabin through a special support method, and then connected to a unified rigid foundation for vibration isolation; while the vacuum system is supported separately from the vibration isolation platform, and is separated from the optical system. The connection is flexible, and the structural characteristics determine that the force at the connection does not change with the change of vacuum degree.

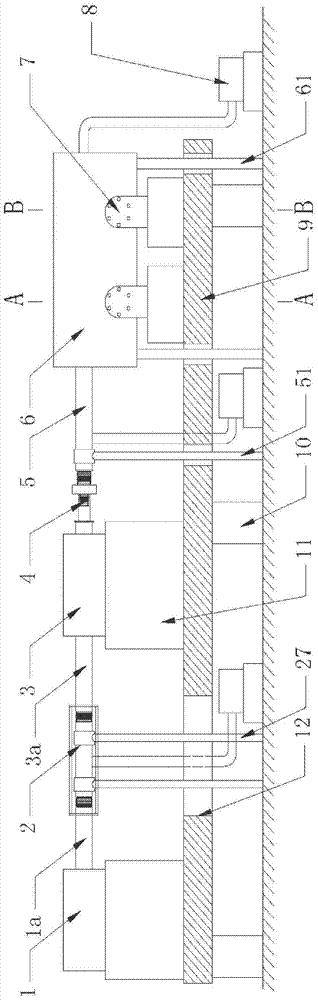

[0033] see figure 1 Example 1 of a typical detection system of an ultraviolet spectrometer is shown: it includes a light source 1, an air extraction device 2, an ultraviolet monochromator 3, a connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com