A method of forming a semiconductor device

A semiconductor and device technology, applied in the field of semiconductor preparation, can solve the problems affecting the process of metal deposition process, affecting the quality of gate, difficult to remove by-products, etc., to achieve the effect of inhibiting the formation of by-products and avoiding ion diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

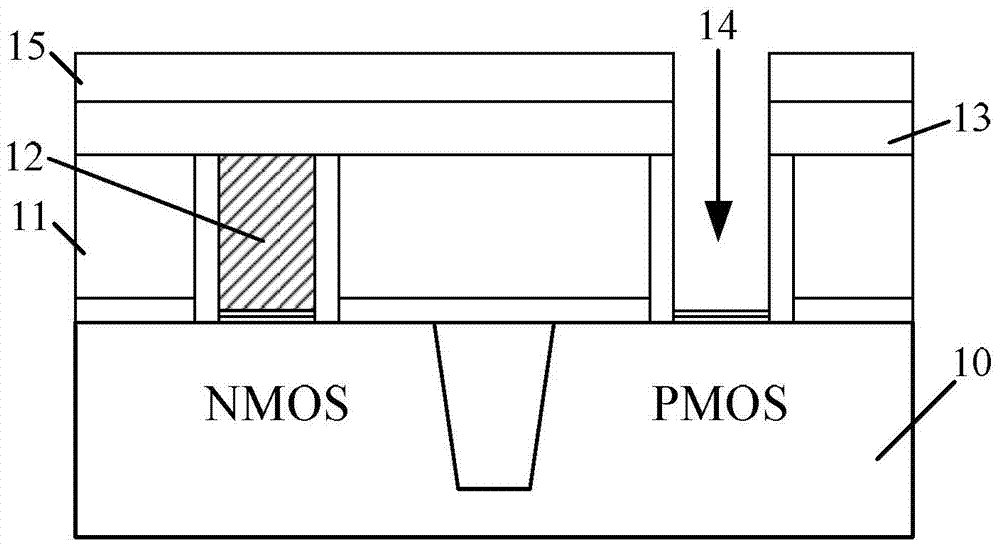

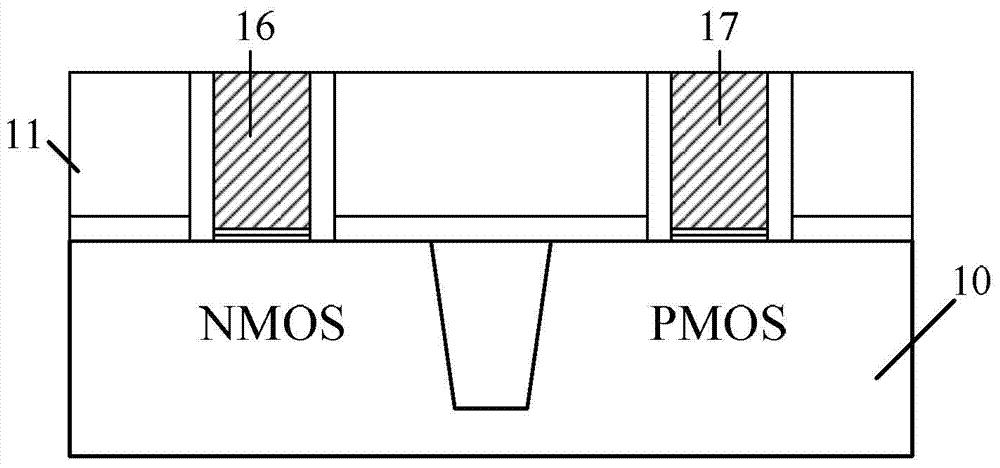

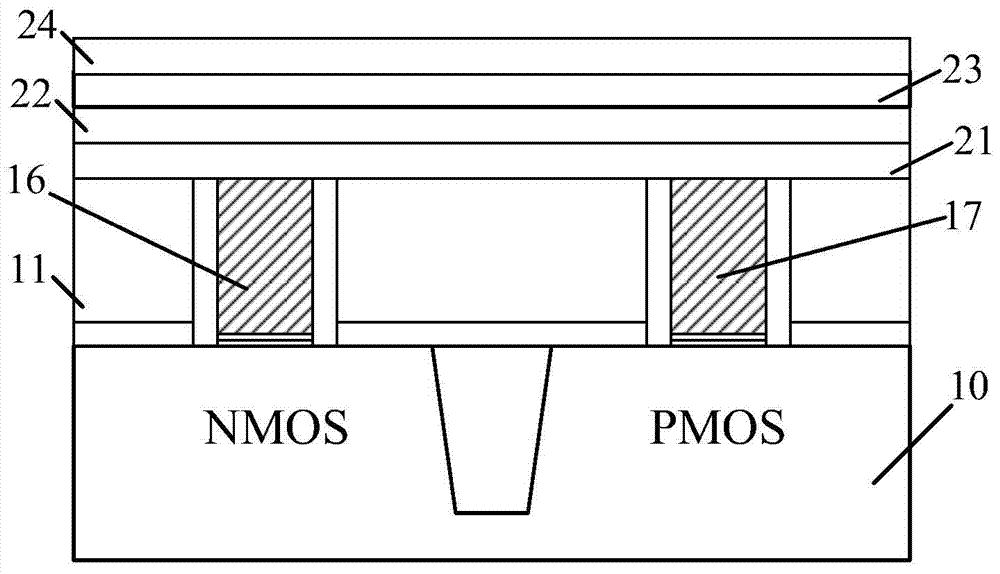

[0031] As mentioned in the background art, with the increase of the integration level of integrated circuits, the device size of integrated circuits decreases continuously, and the quality requirements for devices become more and more stringent. For example, in the CMOS gate preparation process, the last gate (gate last) process has gradually replaced the front gate (gate first) process, so as to avoid the formation of the source region and the drain region in the front gate process, after the source and drain ion implantation is completed. The annealing process causes damage to the gate.

[0032] However, in the actual operation of the gate-last process, it is found that when the patterned photoresist layer is used to etch the hard mask layer, thereby exposing the dummy gate to be etched, and using the hard mask layer as a mask to etch In the process of removing the dummy gate by etching, a large number of by-products will be formed, and these by-products are difficult to rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com