PCB (printed circuit board) heat-radiation soldering pad used for QFN (quad flat no-lead package) chip, and QFN chip and PCB soldering method

A technology of heat dissipation pad and welding method, which is applied in the directions of printed circuit parts, electrical components, electric solid devices, etc., can solve the problems of reduced solder volume, poor soldering, and inability to reach the soldering surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

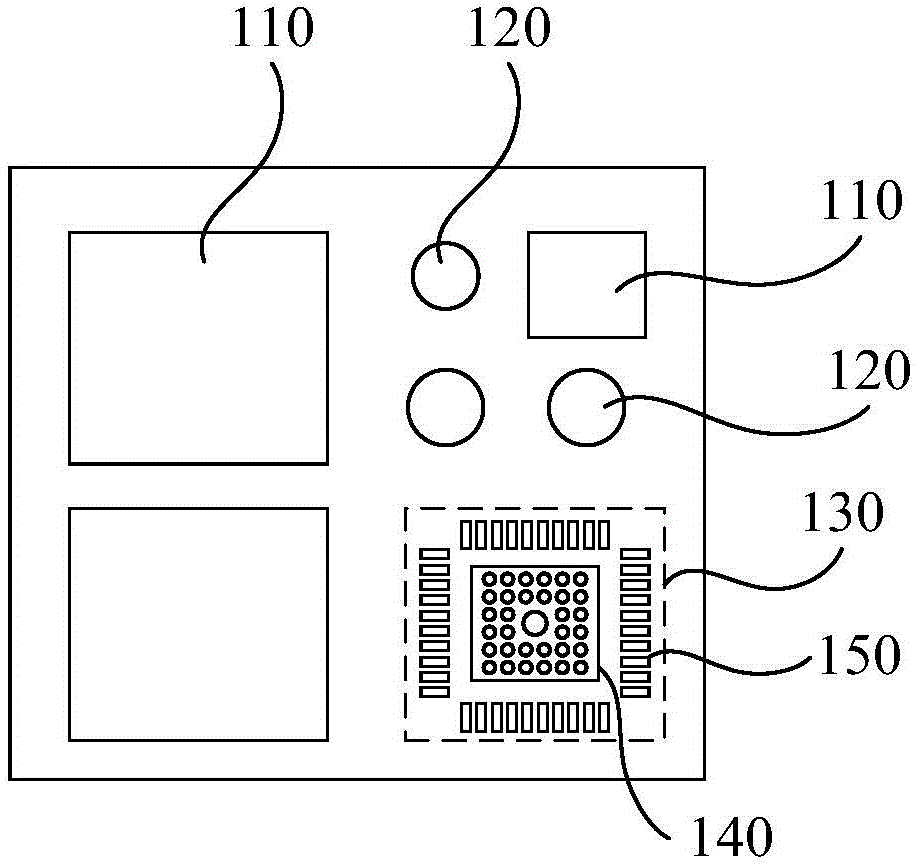

[0026] Such as image 3 Shown is a schematic diagram of the PCB planar structure of an embodiment. QFN chips can be mounted on the PCB 10 . Various chips 110 and components 120 can be mounted on the PCB 10 , and the chips 110 and components 120 are interconnected through wires embedded in the PCB 10 . In order to mount the QFN chip, the PCB 10 is provided with a pad area 130 for soldering the QFN chip. The pad area 130 has a thermal pad 140 and a lead pad 150 surrounding the thermal pad 140 . The heat dissipation pad 140 is consistent with the size of the exposed pad of the QFN chip to be soldered, and the number and size of the pin pads 150 are consistent with the number and size of the pin area of the QFN chip to be soldered.

[0027] Such as Figure 4 Shown is an enlarged view of the thermal pad 140 . The heat dissipation pad 140 is a metal plate with good thermal conductivity, such as an aluminum plate or a copper plate. The metal plate body is provided with a heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com