Thin film transistor, preparation method thereof, array substrate and display device

A thin-film transistor and thin-film technology, applied in the direction of transistors, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems of strong diffusion ability of electrodes or wires, poor display devices, and easy oxidation, so as to improve anti-oxidation ability and avoid Bad display device, avoid the effect of bad display device or abnormal display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

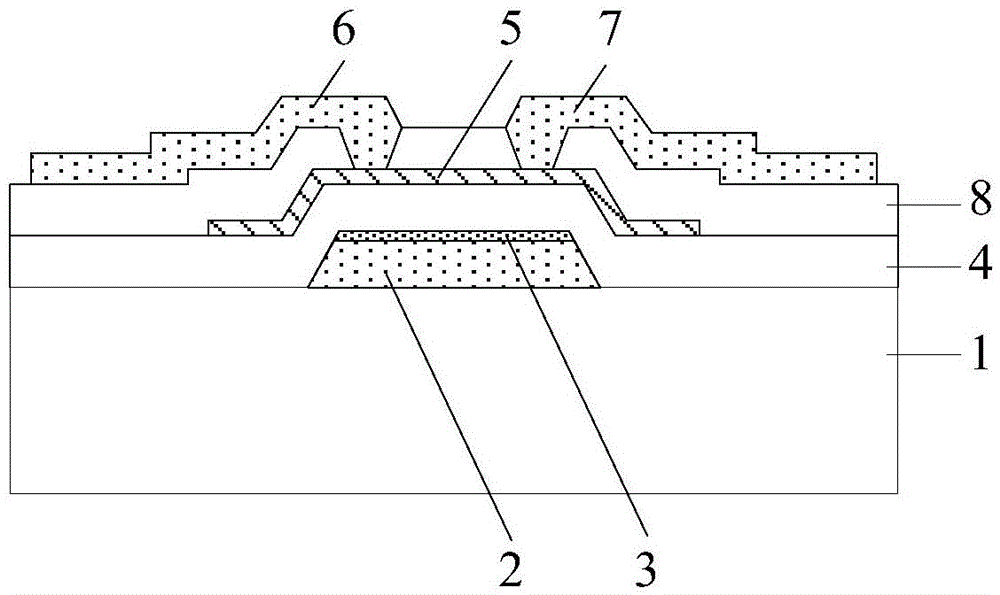

[0034] see figure 1 The first thin film transistor provided by the embodiment of the present invention includes a base substrate 1, a gate electrode 2 formed of pure copper material, a gate insulating layer 4, an active layer 5, a source electrode 6, and a drain electrode 7. The thin film transistor also The copper alloy film layer 3 is included, and the copper alloy film layer 3 is arranged on the side of the gate electrode 2 facing the active layer 5 . In this embodiment, a copper alloy film layer 3 is provided on the side of the gate electrode 2 of the thin film transistor facing the active layer 5, and the accumulation of alloy elements in the copper alloy film layer 3 at grain boundaries, crystal planes, and surfaces can prevent copper atoms from Diffusion to the active layer 5 can also improve the oxidation resistance of the gate electrode 2, thereby avoiding the failure of the thin film transistor or the problem of poor display or abnormal display caused by mura defects...

Embodiment 2

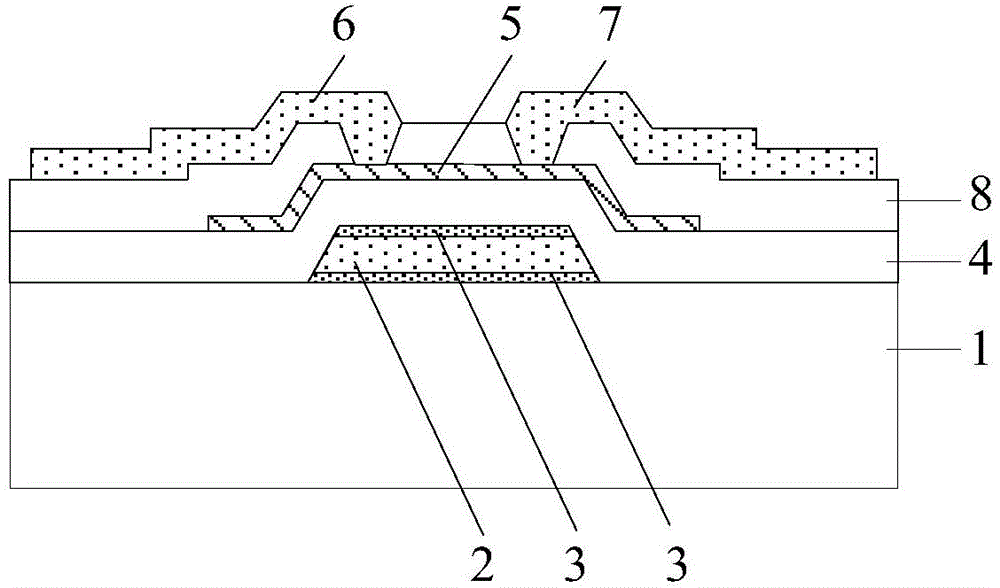

[0039] see figure 2 The second thin film transistor provided by the embodiment of the present invention includes a base substrate 1, a gate electrode 2 formed of pure copper material, a gate insulating layer 4, an active layer 5, a source electrode 6, and a drain electrode 7. The thin film transistor also The copper alloy film layer 3 is included, and the copper alloy film layer 3 is arranged on the side of the gate electrode 2 facing the active layer 5 . and figure 1 The TFT shown is different in that a copper alloy film layer 3 is also provided on the side of the gate electrode 2 of the TFT that faces away from the active layer 5 . In this embodiment, a copper alloy film layer 3 is provided above and below the gate electrode 2 of the thin film transistor, and the alloy elements in the copper alloy film layer 3 accumulate at grain boundaries, crystal planes, and surfaces, for example, the gate electrode 2 faces the The accumulation of alloy elements in the copper alloy fil...

Embodiment 3

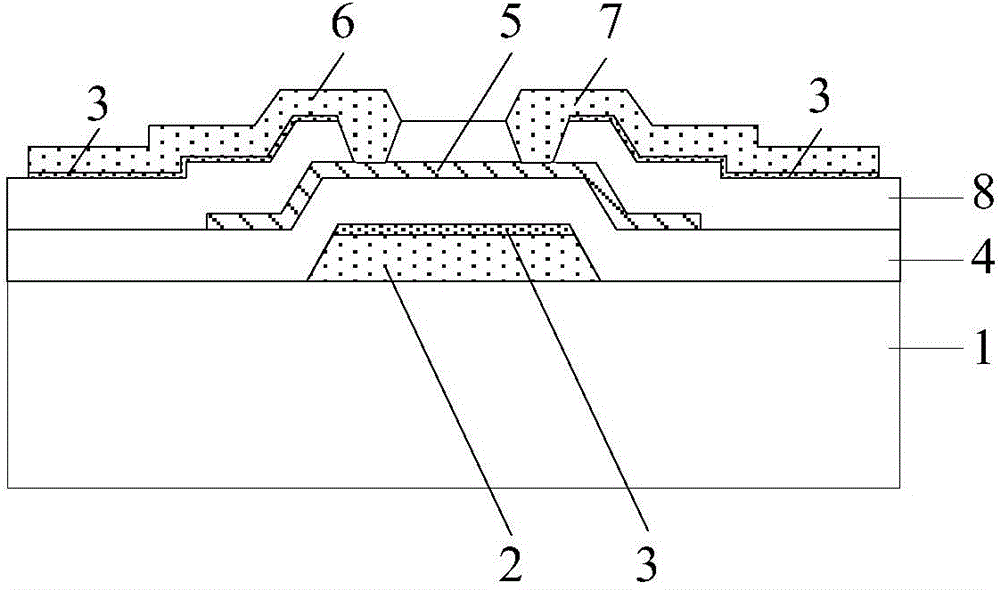

[0044] see image 3 The third thin film transistor provided by the embodiment of the present invention includes a base substrate 1, a gate electrode 2 formed of pure copper material, a gate insulating layer 4, an active layer 5, a source electrode 6, and a drain electrode 7. The thin film transistor also The copper alloy film layer 3 is included, and the copper alloy film layer 3 is arranged on the side of the gate electrode 2 facing the active layer 5 and on the sides of the source electrode 6 and the drain electrode 7 facing the active layer 5 . In this embodiment, a copper alloy film layer 3 is provided on the side of the gate electrode 2 of the thin film transistor facing the active layer 5, and the sides of the source electrode and the drain electrode facing the active layer, and the alloy elements in the copper alloy film layer 3 are in the crystal The accumulation at the boundaries, crystal planes, and surfaces can prevent the diffusion of copper atoms to the active lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com