High-reliability speed measuring type double-way speed measuring structure of motor

A reliable and speed measurement technology, applied in the direction of structural connection, electrical components, electromechanical devices, etc., can solve the problems of increasing system maintenance costs and maintenance costs, vehicle systems not working properly, delaying the normal operation of vehicles, etc., to reduce maintenance costs and The effect of reducing maintenance costs, maintenance time and maintenance costs, and improving the reliability of speed measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

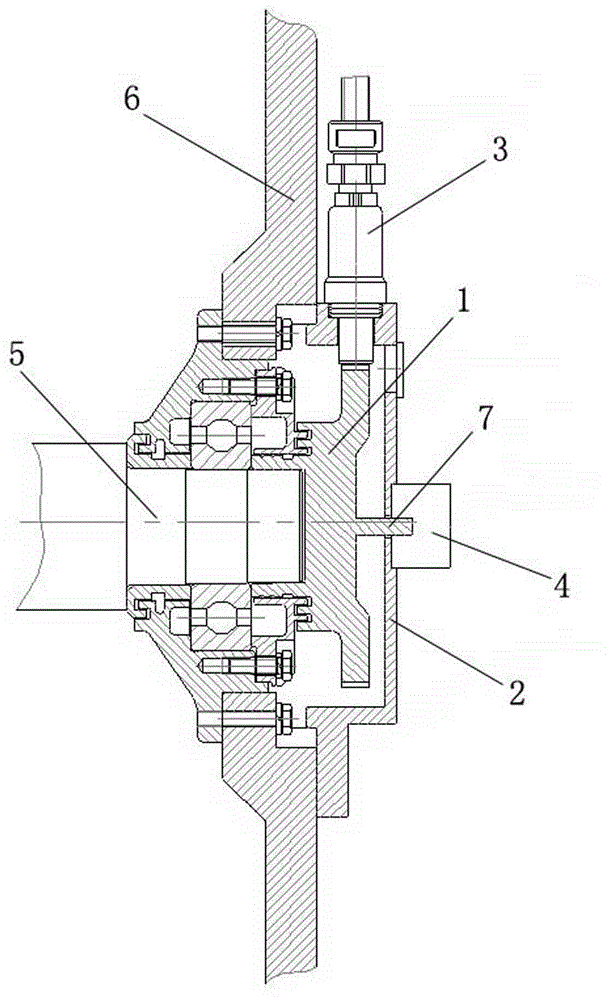

[0014] Such as figure 1 As shown in the figure, a two-way speed measurement structure with high reliability of motor speed measurement includes a speed measurement gear 1, a mounting cover 2, a speed sensor 3 and a speed measurement encoder 4; wherein, the speed measurement gear 1 is installed and fixed on the outer end of the motor shaft 5 The installation cover 2 is installed and fixed on the motor end cover 6 and the speed measuring gear 1 is located in the installation cover 2; the speed measuring sensor 3 is installed and fixed on the side wall of the installation cover 2 and the input end of the speed measuring sensor 3 is facing the outer circular gear of the speed measuring gear 1; The encoder 4 is installed and fixed at the center of the top wall of the installation cover 2; the axis of the speed measuring gear 1 is extended outwardly with a speed measuring shaft 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com