Energy-saving anti-season edible fungi cultivation greenhouse capable of reducing temperature

An edible fungus and off-season technology, which is applied in the field of off-season edible fungus cultivation greenhouses, can solve problems such as economic loss, poor air convection, and poor commodity properties, and achieve the effect of air convection exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

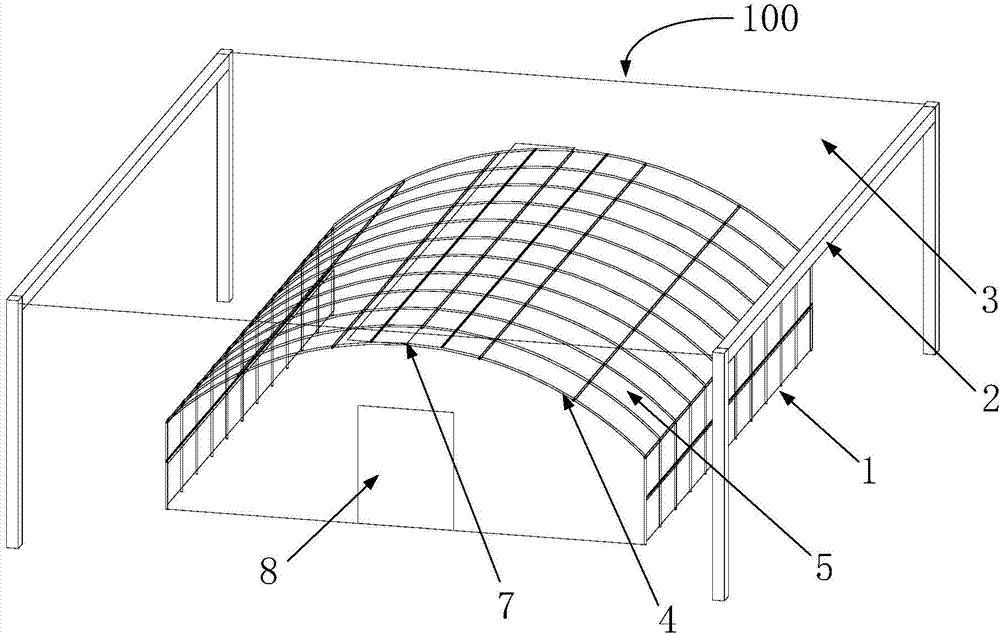

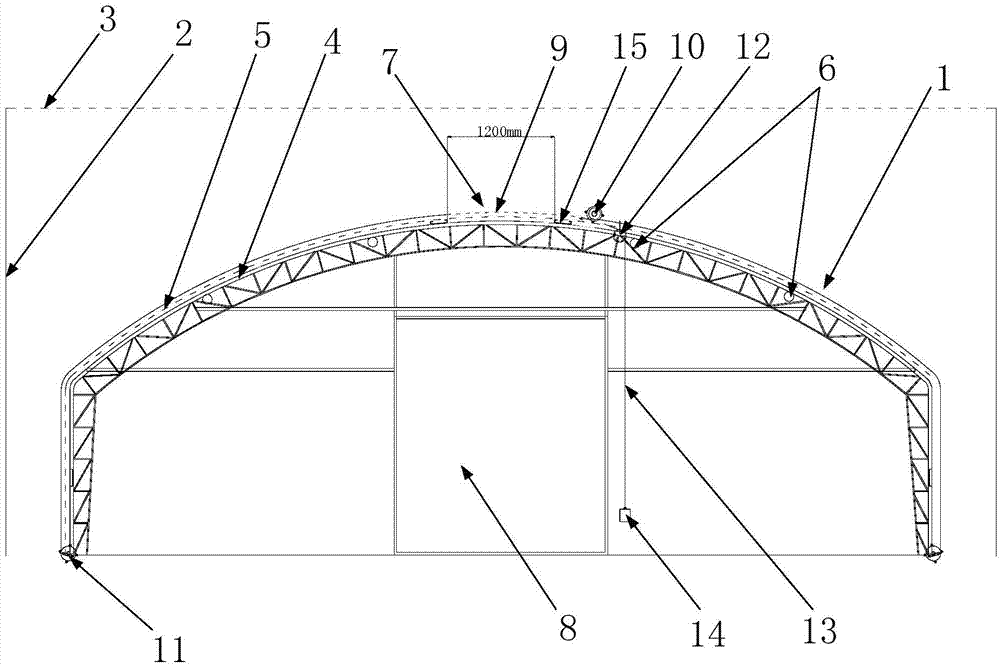

[0015] Such as figure 1 , figure 2 As shown, the cooling and energy-saving off-season edible fungus cultivation greenhouse 100 provided by the present invention includes a mushroom shed 1, a steel frame 2 arranged on the outside of the mushroom shed 1, and a sunshade net 3 installed and fixed on the steel framework 2, and the sunshade net 3 is located above the mushroom shed 1 and covers the whole mushroom shed 1, so as to achieve the purpose of shading the mushroom shed 1. Wherein, the mushroom shed 1 includes a steel (this is an example only, not limited to this) scaffolding 4, a plastic (only this as an example, not limited to this) film 5 that is arranged on the outside of the entire scaffold 4, and is arranged on the shed. The micro nozzle 6 below the frame 4 and the shed door frame 8 arranged on the front face of the mushroom shed 1, the micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com