Method and system capable of enabling cassiterite to be separated from pyrrhotite

A pyrrhotite and separation device technology, which is applied in the field of mineral processing, can solve the problems of reducing the grade and recovery rate of tin concentrate, and cannot completely remove pyrrhotite, and achieves low production cost, simple structure, improved grade and recovery rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

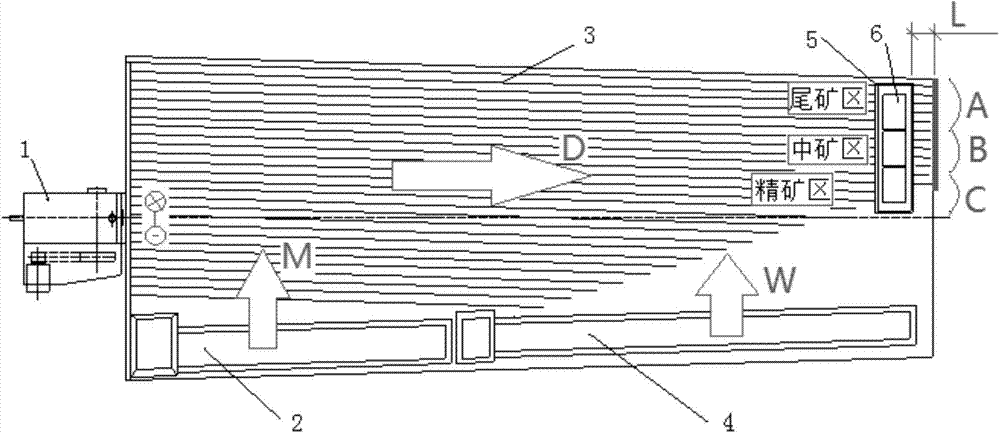

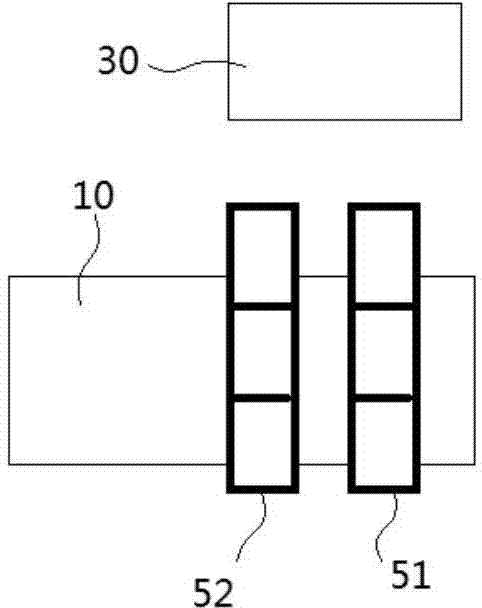

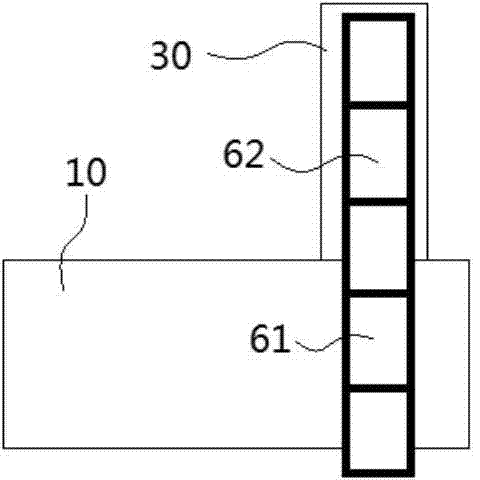

[0039] in the attached figure 1 In the shown embodiment, the reference numeral 1 represents the head of the shaker, the reference numeral 2 represents the feed tank, the reference numeral 3 represents the bed bar of the shaker, the reference numeral 4 represents the water supply tank, and the reference numeral 5 represents the stainless steel box , Reference numeral 6 represents a permanent magnet block.

[0040] According to the present invention, the device capable of separating cassiterite and pyrrhotite is suspended above the shaker bed surface, at a position 300-400mm away from the concentrate end, the suspension height is 20-30mm higher than the flushing water of the shaker, and the suspension direction is the same as The direction of incoming material is vertical, and the length of the separation device for cassiterite and pyrrhotite completely covers the width of the slurry on the shaker surface, which acts as an intercepting net in the air.

[0041] When the shaking ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com