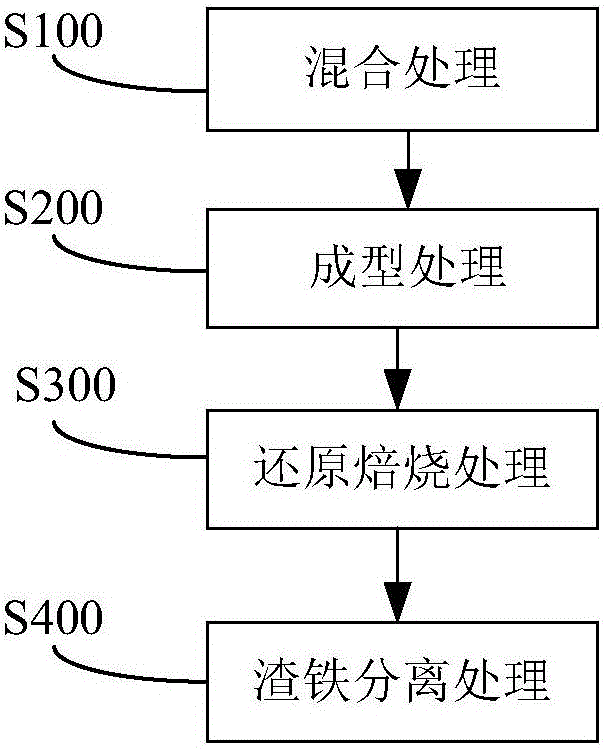

Method and system for processing red mud

A technology of red mud and import, which is applied in the field of red mud treatment, can solve the problems that affect the comprehensive utilization of slag or tailings, the low dealkalization rate, and the direct reduction treatment method of red mud to be studied, so as to prevent the difficulty of discharging and low alkali Metal content, effect of promoting volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

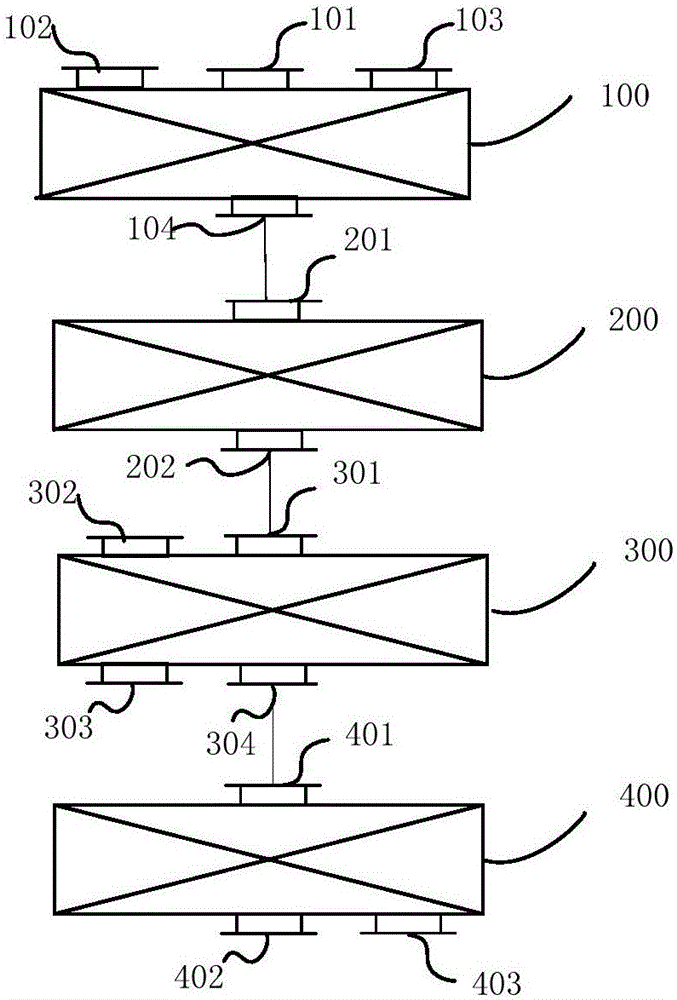

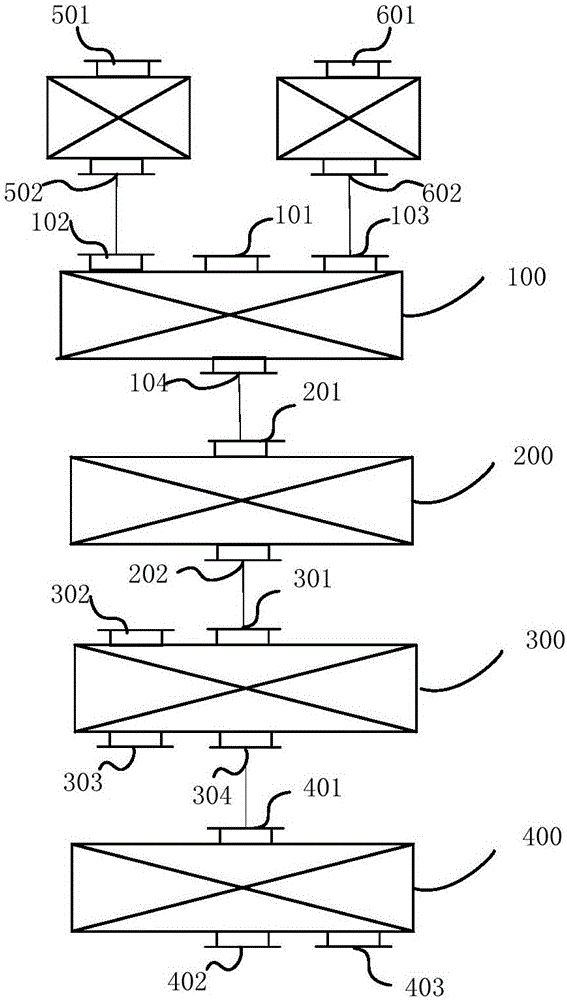

Method used

Image

Examples

Embodiment 1

[0066] Utilize the method for the embodiment of the present invention, red mud is processed, and specific method is as follows:

[0067] (1) Crush the high volatile coal powder to 2mm, grind the high fixed carbon coal powder to -0.074mm, dry the red mud and moisten it until the particle size is uniform (-0.043mm accounts for 80%).

[0068] (2) batching the material obtained in step (1), wherein the red mud is 100 parts by weight, mixed with 12% high volatile coal powder, 25% high fixed carbon coal powder, and 8% limestone as an additive , mix the materials evenly, wherein, the fixed carbon content of the high fixed carbon reducing agent is 82%, the volatile content of the high volatile content pulverized coal is 38%, and the total iron content of the red mud is 35%.

[0069] (3) Mix the mixture prepared in step (2), add an appropriate amount of water, and perform wet mixing, and then press balls on rollers under high pressure to obtain pellets.

[0070](4) The pellets are dri...

Embodiment 2

[0074] Utilize the method for the embodiment of the present invention, red mud is processed, and specific method is as follows:

[0075] (1) The high volatile coal powder is crushed to 4mm, the high fixed carbon coal powder is ground to 0.1mm, and the red mud is dried and then moistened to a uniform particle size (-0.043mm accounts for 80%).

[0076] (2) batching the material obtained in step (1), wherein the red mud is 100 parts by weight, mixed with 15% high volatile coal powder, 25% high fixed carbon coal powder, and 8% limestone as an additive , mix the materials evenly, wherein, the fixed carbon content of the high fixed carbon reducing agent is 82%, the volatile content of the high volatile content pulverized coal is 38%, and the total iron content of the red mud is 35%.

[0077] (3) Mix the mixture prepared in step (2), add an appropriate amount of water, and perform wet mixing, and then press balls on rollers under high pressure to obtain pellets.

[0078] (4) The pel...

Embodiment 3

[0082] Utilize the method for the embodiment of the present invention, red mud is processed, and specific method is as follows:

[0083] (1) The high volatile coal powder is crushed to 0.1mm, the high fixed carbon coal powder is ground to 0.074mm, and the red mud is dried and then moistened to a uniform particle size (-0.043mm accounts for 80%).

[0084] (2) batching the material obtained in step (1), wherein the red mud is 100 parts by weight, mixed with 15% high volatile coal powder, 25% high fixed carbon coal powder, and 8% limestone as an additive , mix the materials evenly, wherein, the fixed carbon content of the high fixed carbon reducing agent is 82%, the volatile content of the high volatile content pulverized coal is 38%, and the total iron content of the red mud is 35%.

[0085] (3) Mix the mixture prepared in step (2), add an appropriate amount of water, and perform wet mixing, and then press balls on rollers under high pressure to obtain pellets.

[0086] (4) The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com