Composite collecting agent and application thereof in chalcopyrite flotation

A technology of composite collectors and agents, applied in flotation, solid separation, etc., can solve problems such as poor merger effect, sticky flotation foam, serious entrainment of flotation foam, etc., to reduce foam entrainment and improve foam stickiness , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A composite collector of the present invention is 2-phosphonic acid butane-1,2,4-tricarboxylic acid and butyl xanthate with a mass ratio of 8:2.

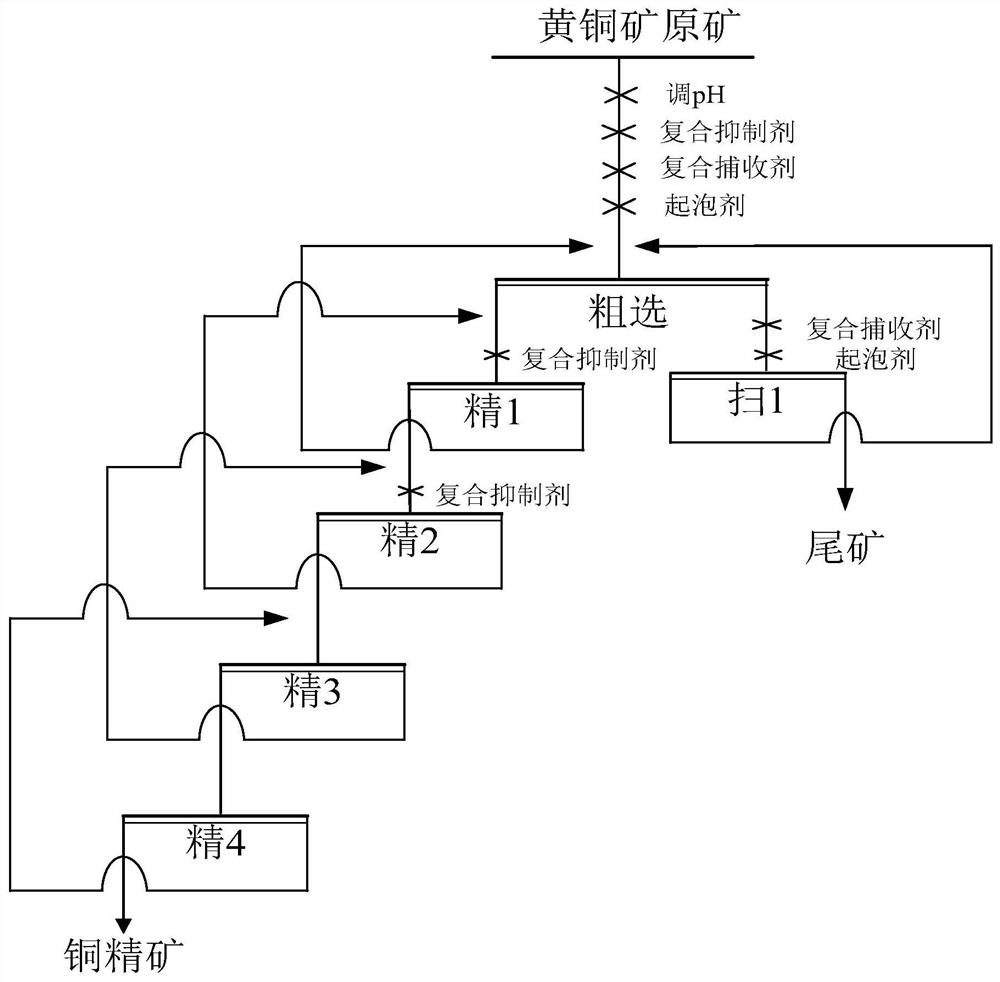

[0033] The composite inhibitor of this embodiment is applied in the flotation process of a chalcopyrite in Gansu (Cu grade is 0.45%, gangue is mainly quartz, calcite, pyrite and magnetite), and its process flow chart is as follows figure 1 As shown, the specific process is as follows: First, grind the chalcopyrite to below -0.074mm, the mass ratio of -0.074mm ore accounts for 70%, and the pulp concentration is 45%, then adjust the pH of the pulp to 8 with sodium carbonate, and add compound inhibitors (a mixture of water glass, glyceric acid and sodium carboxymethyl cellulose with a mass ratio of 4:3:3) and composite collector (add 2-phosphonic acid butane-1,2,4-tricarboxylic acid first , and then add butyl xanthate, the mass ratio of 2-phosphonic acid butane-1,2,4-tricarboxylic acid to butyl xanthate is 8:2, and the medicamen...

Embodiment 2

[0056] A composite collector of the present invention, comprising trimethylphosphonoacetate and ethylthiazide in a mass ratio of 6:4.

[0057] The composite inhibitor of this embodiment is applied to the flotation process of a certain high-grade chalcopyrite in Tibet (Cu grade is 0.65%, the gangue minerals are mainly quartz, feldspar and pyroxene, and the pyrite content is less). The process is as follows: the chalcopyrite is ground to -0.074mm, the mass ratio of -0.074mm ore accounts for 65%, the pulp concentration is 40%, then the pH of the pulp is adjusted to 9 with sodium carbonate, and a compound inhibitor (mass ratio of 6 : 3:1 water glass, oxalic acid and sodium carboxymethyl cellulose) and composite collector (first add trimethylphosphonoacetate, then add ethiazide, trimethylphosphonoacetate and ethyl The mass ratio of sulfur to nitrogen is 6:4, and the medicament of the composite collector needs to be added separately in the follow-up process), and at room temperature...

Embodiment 3

[0059] A composite collector of the present invention comprises 2-hydroxyphosphonoacetic acid and butylammonium black medicine with a mass ratio of 7:3.

[0060] The composite inhibitor of this embodiment is applied in the flotation process of a certain high-sulfur low-copper chalcopyrite in Jiangxi (Cu grade is 0.34%, gangue minerals are mainly pyrite, feldspar and dolomite, and a small amount of quartz), The specific process is as follows: the chalcopyrite is ground to -0.074mm, the ore mass ratio accounts for 60%, and the pulp concentration is 35%, then sodium carbonate is used to adjust the pH of the pulp to 10, and a compound inhibitor is added (the mass ratio is 6:1 :3 mixture of water glass, malonic acid and sodium carboxymethyl cellulose) and composite collector (add 2-hydroxyphosphonoacetic acid earlier, then add butyl ammonium black medicine, and 2-hydroxyphosphonoacetic acid and The mass ratio of ammonium butyl ammonium black medicine is 7:3, and the medicament of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com