Intelligent water-saving system of RO (reverse osmosis) machine

A water-saving system and intelligent technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of heavy workload, rigid working principle and shortened life of RO membranes and pumps and other issues, to achieve the effect of reducing waste of water resources, intelligent machine work, and reducing unnecessary consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

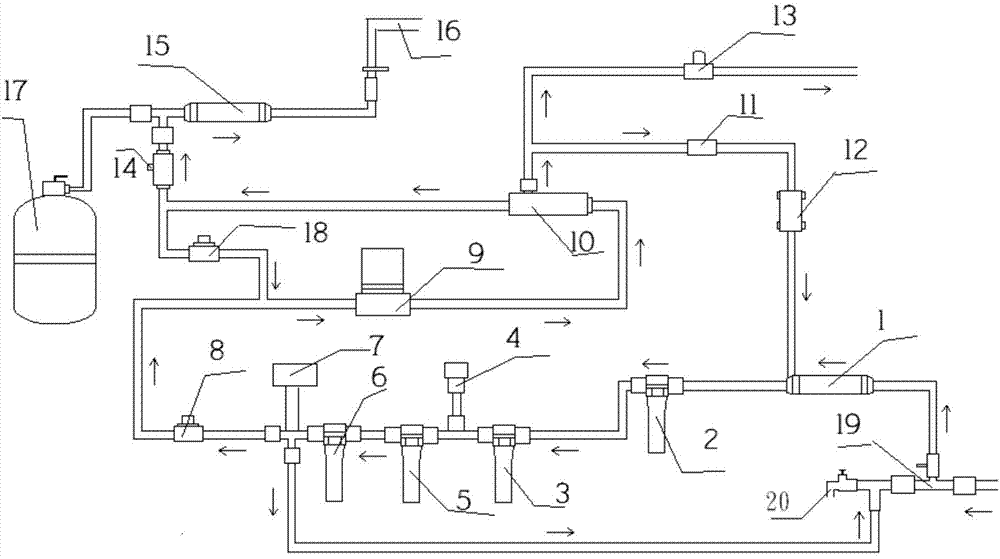

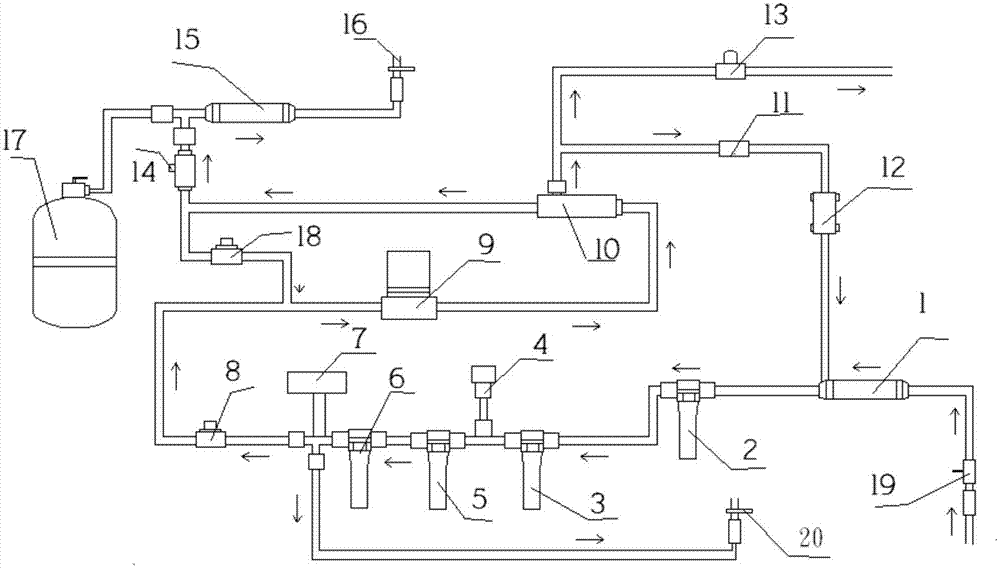

[0020] see figure 1 , is the schematic diagram of the side water inlet of the embodiment of the RO machine intelligent water-saving system of the present invention. see figure 2 , is the principle diagram of water intake under the embodiment of the RO machine intelligent water-saving system of the present invention. like figure 1 , figure 2 As shown, in the RO machine intelligent water-saving system provided in the first embodiment of the present invention, at least include, sequentially connected water quality pretreatment module, return water concentration dilution and reuse module, automatic control module, separation and recovery of RO purified water and the use module; the water quality pretreatment module includes an anti-scaling device 1, a first filter 2, and a second filter 6, which are mainly used to initially purify and soften the incoming water, remove sediment, algae, large bacteria, impurities, etc. Prepare for RO membrane fine filtration, reduce RO membran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com