Heat-resistant antimicrobial polylactic acid material and preparation method thereof

A polylactic acid material and polylactic acid technology are applied in the field of heat-resistant and antibacterial polylactic acid materials and their preparation, and can solve problems such as no public reports.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

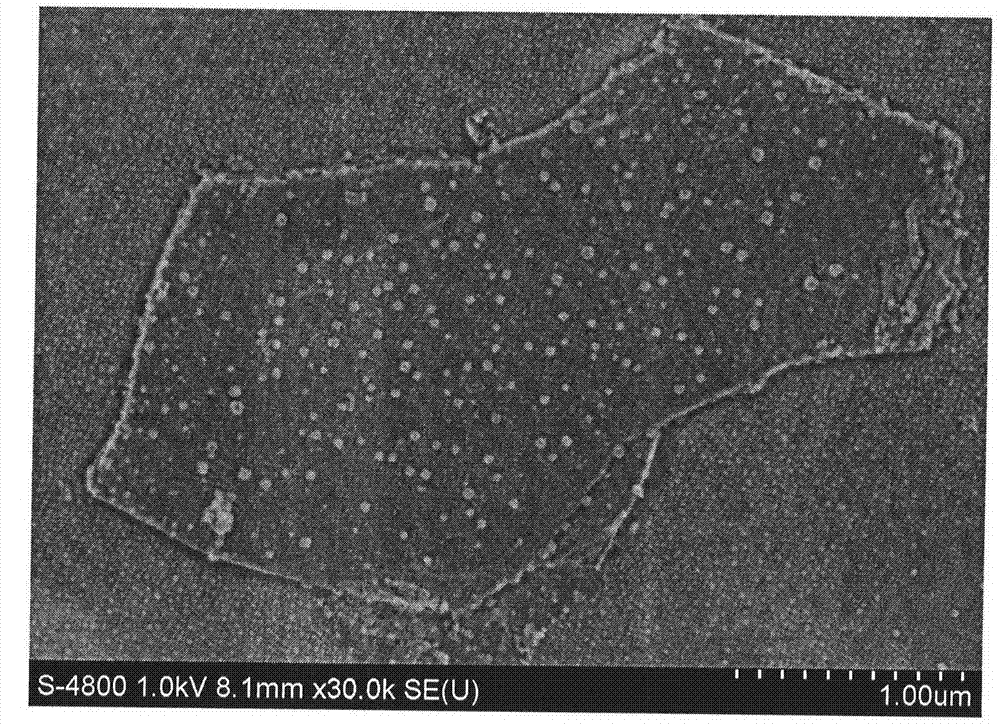

[0022] 1) Add 20mM silver nitrate aqueous solution dropwise to 5ml 0.5mg / ml graphene oxide aqueous solution with a diameter of 100nm and a thickness of 1nm in 5 drops, 1ml each time. Then stir vigorously at room temperature for 48 hours, then centrifuge at 10,000 rpm for 20 minutes, wash the centrifuged precipitate with deionized water, and dry it in a vacuum oven at 50 degrees for 12 hours. Graphene nanocomposites.

[0023] 2) Disperse the nano-silver / graphene oxide nanocomposite material obtained in step 1) in lactic acid, prepare a solution with a concentration of 0.1g / L, and then use an ultrasonic device with a power of 300W to ultrasonically treat the solution for 0.5 hours, Obtain nano-silver / graphene oxide nanocomposite lactic acid solution;

[0024] 3) Put the ultrasonically treated mixed solution in step 2) into a vacuum oven at a temperature of 50 degrees Celsius, and vacuum bake for 10 hours until the mixed solution has no residual water;

[0025] 4) To obtain the...

Embodiment 2

[0028] 1) Add 10mM silver nitrate aqueous solution dropwise to 5ml 0.5mg / ml graphene oxide aqueous solution with a diameter of 5μm and a thickness of 10nm in 5 drops, 1ml each time. Then stir vigorously at room temperature for 36 hours, then centrifuge at 10,000 rpm for 5 minutes, wash the centrifuged precipitate with deionized water, and dry it in a vacuum oven at 80 degrees for 5 hours. Graphene nanocomposites.

[0029] 2) disperse the nano-silver / graphene oxide nanocomposite material obtained in step 1) in lactic acid, prepare a solution with a concentration of 20g / L, and then use an ultrasonic device with a power of 1000W to ultrasonicate the solution for 5 hours to obtain Nano silver / graphene oxide nanocomposite lactic acid solution;

[0030] 3) Put the ultrasonically treated mixed solution in step 2) into a vacuum oven at a temperature of 80 degrees Celsius, and vacuum bake for 10 hours until the mixed solution has no residual water;

[0031] 4) To obtain the polylacti...

Embodiment 3

[0034] 1) Add 30mM silver nitrate aqueous solution dropwise to 5ml 0.5mg / ml graphene oxide aqueous solution with a diameter of 1 μm and a thickness of 20nm in 5 drops, 1ml each time. Then stir vigorously at room temperature for 24 hours, then centrifuge at 10,000 rpm for 5 minutes, wash the centrifuged precipitate with deionized water, and dry it in a vacuum oven at 80 degrees for 5 hours. Graphene nanocomposites.

[0035] 2) Disperse the nano-silver / graphene oxide nanocomposite material obtained in step 1) in lactic acid, prepare a solution with a concentration of 1g / L, and then use an ultrasonic device with a power of 500W to ultrasonically treat the solution for 1 hour to obtain Nano silver / graphene oxide nanocomposite lactic acid solution;

[0036] 3) Put the ultrasonically treated mixed solution in step 2) into a vacuum oven at a temperature of 50 degrees Celsius, and vacuum bake for 48 hours until the mixed solution has no residual water;

[0037] 4) To obtain the poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com