Hydraulic internal cutter for cutting sleeve in deep sea

A hydraulic and casing technology, applied in wellbore/well components, earth-moving drilling, etc., can solve the problems of prone to cutting accidents, complex structure and operation, affecting cutting efficiency, etc., to achieve improved cutting efficiency, convenient operation, The effect of the overall structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

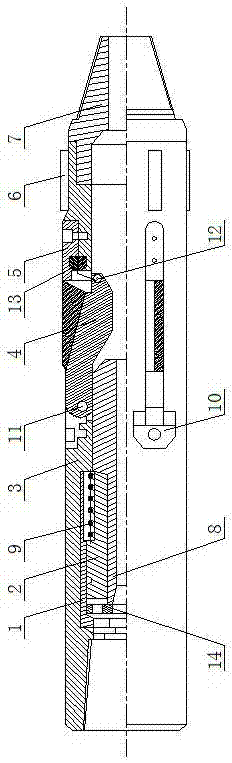

[0019] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

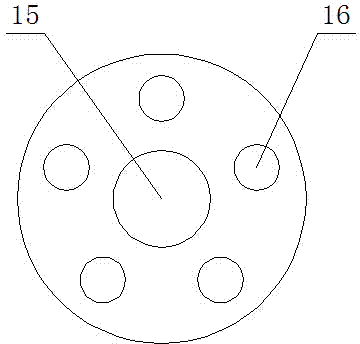

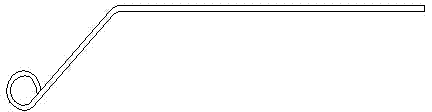

[0020] The hydraulic inner cutter for deep-sea cutting casing consists of a cylinder liner 1, a housing 3, a limit block 5, a centralizer 6, a lower joint 7, a leaf spring 12, a pressing block 13, a cutter assembly, and a piston assembly. A piston assembly is installed at one end of the housing 3, a lower joint 7 is installed at the other end of the housing 3, a cutter assembly is installed in the middle of the housing 3; a centralizer 6 is installed outside the housing 3; the middle of the piston assembly, the lower The middle of the joint 7 is formed with a flow channel; the piston assembly is composed of a piston 2, a central body 8, a spring 9, and a valve disc 14; the cutter assembly is composed of a knife body 4, a knife holder 10, and a pin shaft 11; the centralizer 6 is composed of It consists of six centralizing blocks evenly distributed along the cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com