A method of adjustable multi-suitable formwork support and gob-side entry retention in fully mechanized mining face with large mining height

A technology of fully mechanized mining face and large mining height, applied in mining equipment, earthwork drilling, filling and other directions, can solve the problems of poor roofing effect of filling body, affecting the effect of empty entry retaining, unsafe working environment, etc. The effect of reducing construction cost, strong integrity and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

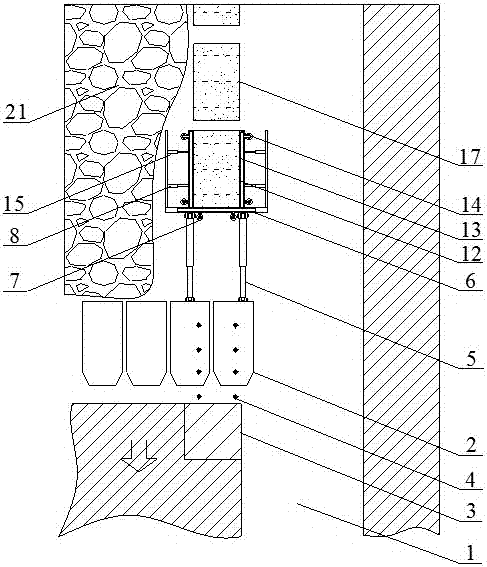

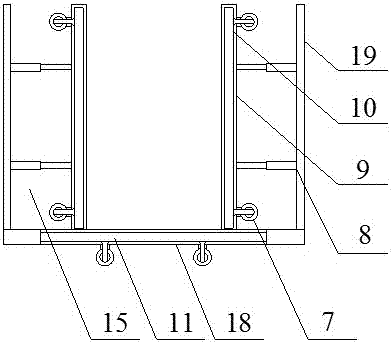

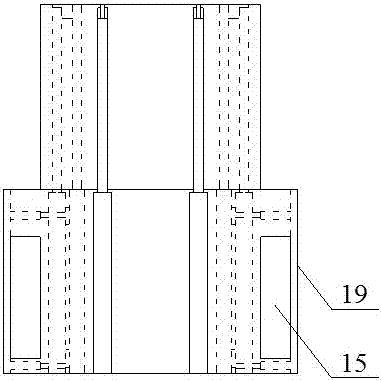

[0024] Such as figure 1 As shown, the method for retaining roadway along the gob with adjustable multi-suit formwork support in the fully mechanized mining face with large mining height of the present invention, its steps are as follows:

[0025] a. As the working face advances, a plurality of end frames 2 are set at the end of the gob-side entry retaining roadway 1, and at the coal body in front of the end frame 2, an advance gap 3 is dug along the top plate, and in the advance gap 3 Anchor rods and anchor cables 4 are installed on the roof to provide support;

[0026] b. Adjust the frame hydraulic cylinder 5 connected with the adjustable multi-fit formwork support 6, so that the adjustable multi-fit formwork support 6 is in the position where the goaf needs to be filled, estimate the width of the filling body according to the area of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com