Double-layer indirect cooling tower

A cooling tower, an indirect technology, applied in the field of energy and power engineering, can solve problems such as uneven flow field and temperature field, reduce air temperature difference and density difference, reduce ventilation volume, etc., to increase natural circulation power, eliminate impact, The effect of increasing the air temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

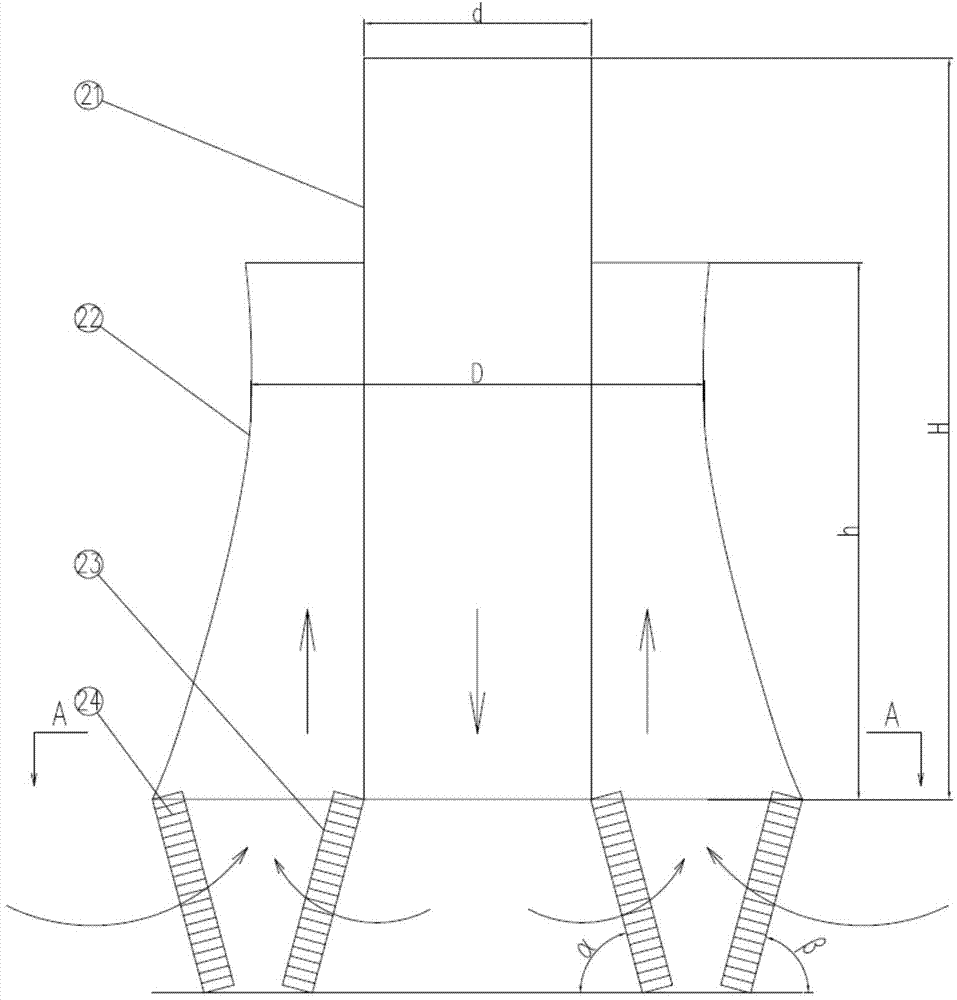

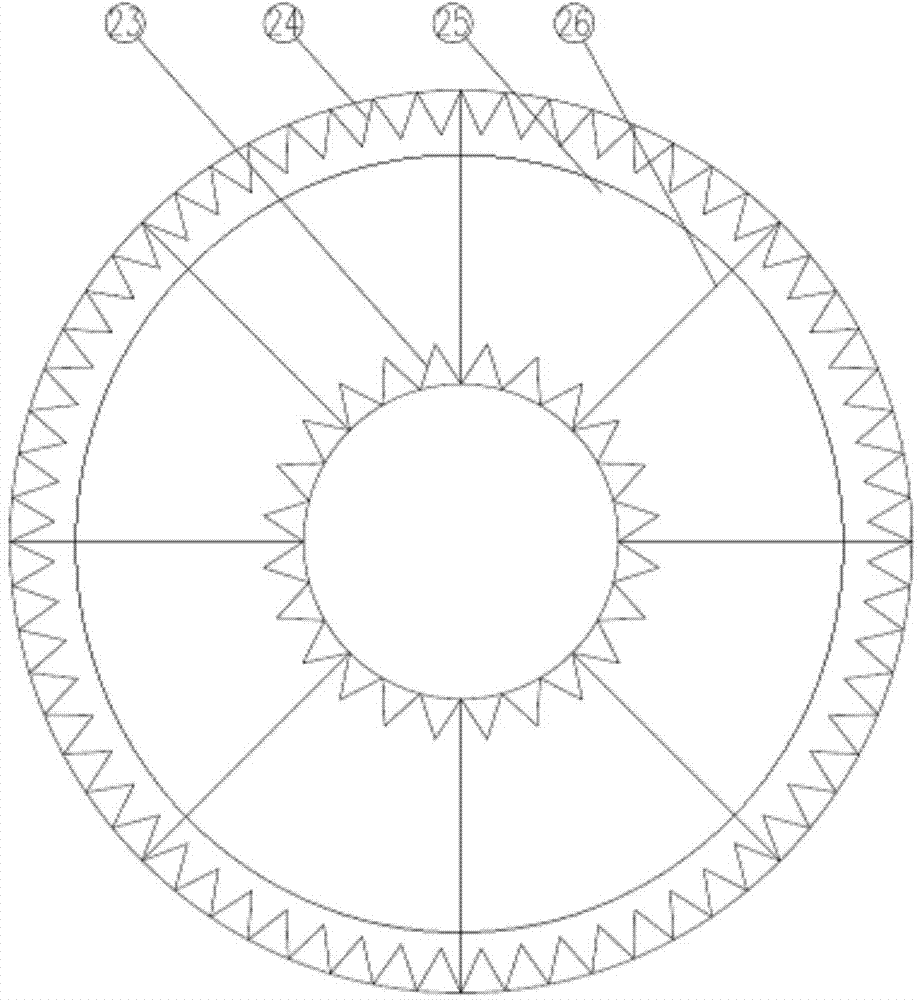

[0032] Such as figure 2 , image 3 As shown, a double-layer indirect cooling tower includes a coaxial, inner and outer nested, bottom-level inner tower tube 21 and an outer layer tower tube 22, the inner layer tower tube 21 and the outer layer tower tube 22 The tower bottoms of the tower tubes 22 are respectively fixed on the same mechanical frame, the outer layer tower tube 22 is a hyperbolic cooling tower, the inner layer tower tube 21 is a cylindrical cooling tower, and the height of the inner layer tower tube 21 is Higher than the height of the outer tower 22, the inner edge of the bottom of the outer tower 22 is placed with an outer oblique radiator 24 at a certain angle to the ground, and the outer bottom of the inner tower 21 is The inner layer inclined radiator 23 is placed at a certain angle with the ground; the bottom is installed on the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com