Preparation method of simulation stress corrosion cracks for eddy current testing

A stress corrosion cracking and eddy current detection technology, which is applied in the preparation of test samples, material magnetic variables, etc., can solve the problems of difficult preparation of artificial stress corrosion crack test pieces, uncontrollable crack parameters, etc., and achieve flexible handling, easy realization, The effect of general applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

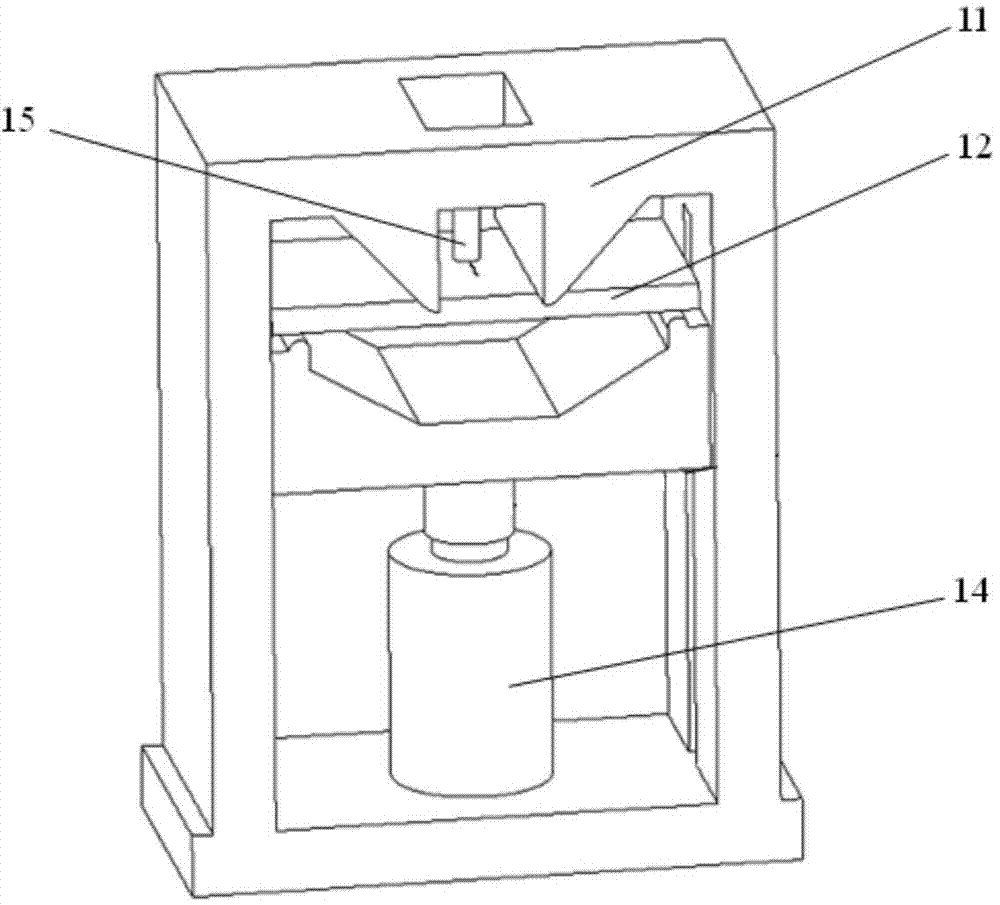

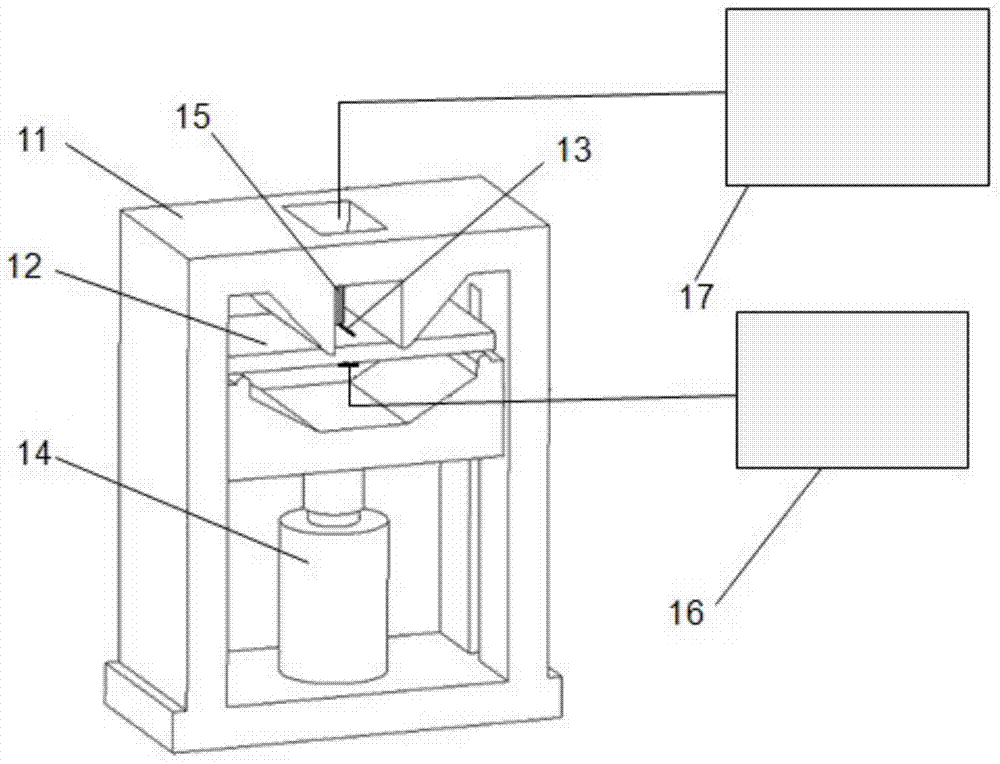

[0029] Such as figure 1 As shown, the principle of the present invention is to use the jack 14 to load the fatigue cracked plate specimen 12 through the four-point bending loading device 11, so that the fatigue crack located in the central part of the fatigue cracked specimen is closed to a certain extent, and the two crack surfaces occur Partial contact produces a conductivity weaker than that of the base material, thereby simulating a real stress corrosion test piece in the sense of eddy current testing.

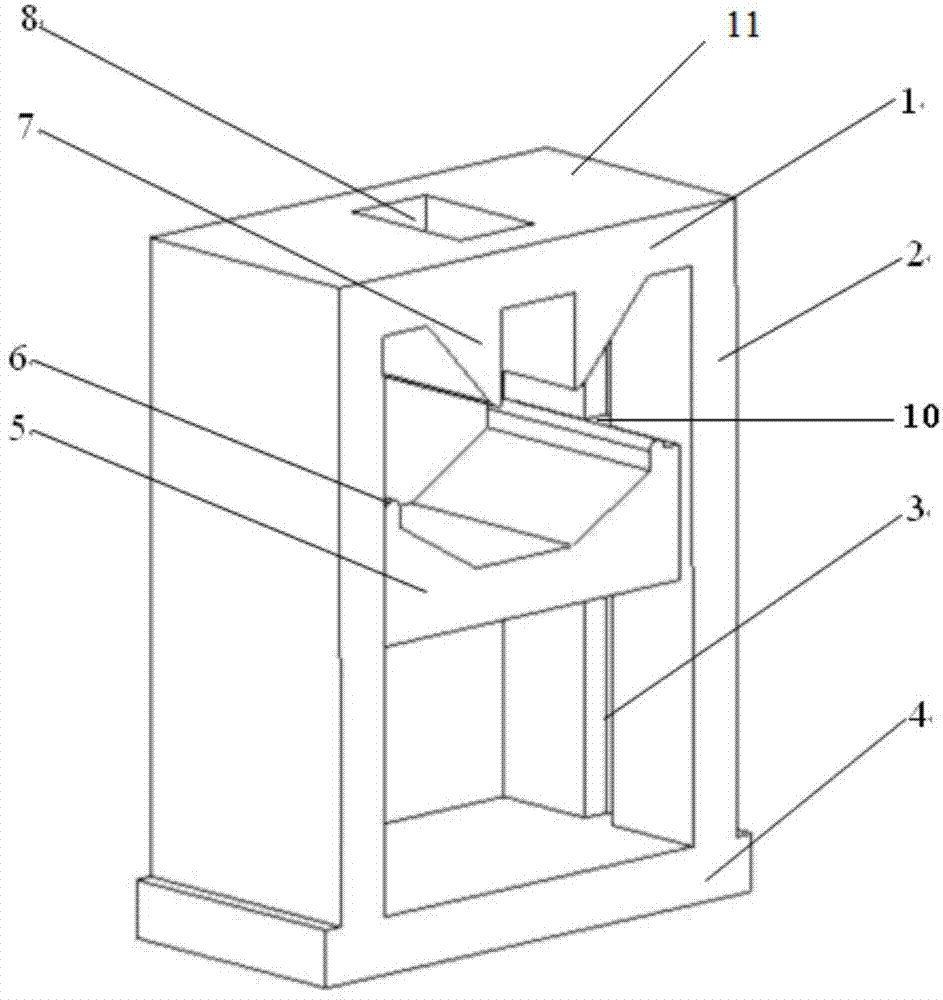

[0030] Such as figure 2 As shown, the structure of the four-point bending online loading device 11 designed by the present invention includes a lower cover plate 4, side plates 2 arranged on both sides of the lower cover plate 4, and a chute 3 is opened on the inner side of the side plate 2, and the slider 5 passes through the two sides of the lower cover plate 4. The slider guide rail 10 on the side is loaded into the chute 3, the center of the slider 5 is a groove, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com